FAQs on pellet making machine, pellet mill, or other related equipment. Common problems when using the pellet machine and how to solve it.

How to define "large wood pellet plant wood pellet manufacturing equipment"? Not only 10t/h new design completely biomass wood pellet production line, 20t/h large biomass pellet production line for wood pellets can be called big capacity wood fuel pellet production line, Different from the production of feed pellets, for the production of wood pellets, even the 2tph high quality ce wood pellet mill line is not a small output. Of course, big or small is always a relative concept, and we just judge it based on the wood pellet market.

1.Introduction of Biomass Wood Fuel Pellets

In natural, there are plenty of biomass energy stored in organic material such as agricultural and forest products. In most developing countries, biomass fuel is generally used for cooking and heating in rural areas in the form of firewood. In developed countries, biomass fuel is widely used in electricity generation industry. Using biomass as the fuel of power plant can ensure continuous fuel supplement, unlike solar and wind, which rely on weather conditions. Wood materials are the main feedstock for large biomass pellet production line. Agricultural residues such as grass, crop straw, peanut shell and rice husk are also hot choice for making pellets with different quality and utilization.

Wood pellets are made from wood residues and wastes such as saw dust, wood chips and shavings. There are plenty of wood wastes produced in the wood processing factories including the manufacture of furniture and lumber. Wood pellets are the most common type of compressed or densified biomass fuel.

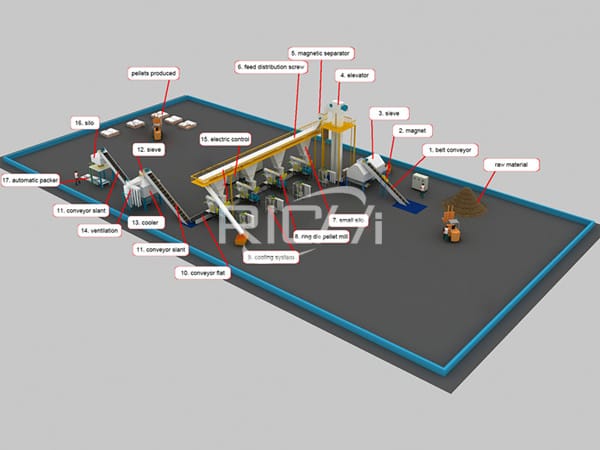

China factory professional design 10-20tph large capacity heavy duty wood pellet line pellet making process can generally be divided into wood crushing, drying,wood pelleting, wood pellets cooling and packing or bagging. Before wood pelletizing, the raw materials need to be processed to certain moisture content and size, so that to meet proper specifications. Sometimes, steam conditioner is used in a pellet plant to soften the wood materials and make them less abrasive to the wood pellet making equipment.

Then in the high quality wood pellet press machine, under high pressure, the crushed biomass materials will be extruded through holes in the pellet die. Because of pressure and fiction, the temperature will increase during the extruding. High temperature helps soften the lignin in wood materials and improve the pelletizing process. When discharged from the wood pellet mill pellet press, the pellets are hot and need to be cooled in the open air or by using wood pellet cooling machine. After cooling, the lignums solidify, and the pellet is formed.

3.What is needed to start a 10-20tph wood pellet plant?

What is needed to start a 10-20tph wood pellet plant?The following will introduce the machines for wood pellet line 10-20 ton per hour.

(1)High efficiency wood chips crusher

This ultimate diagnostic system monitors hydraulic pressures, temperatures, clutch systems and engine efficiency to maximize performance.

(2)Professional factory offer good quality wood hammer mill

Ce certificated wood hammer mill crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials.

(3)Hot selling high quality biomass sawdust rotary dryer

Rotary drum drying machine is mainly used for drying the wood_pellet with a certain degree of humidity and particle size.

(4)Large capacity good performance wood pellet mill

Dual motor driving system, low noise and no need for lubrication, screw feeder adopts frequency converter; Start current is half of single motor gear pellet mill,low working voltage. SKF bearing and Siemens motor;Automatic oil adding device for main shaft and roller.

(5)Wood Pellet Cooling Equipment

Advanced theory of countercurrent cooling, widely applied in wood pellet cooling, such as Granulation, Expansion, extruder, expanded and so on.

(6)Packing Machine

Wood packing machine is applied to pack the wood pellets into bags ,according to a certain speed and weight.Widely used in grain, feed, food, biomass,light structuring and chemical industry.

4.Institute standards of Wood Pellet Fuels

Industry groups have make standards on the density, dimensions and other characteristic of wood pellets. In the United States, a set of standards for wood pellets grading is designed by the pellet fuel institute.

Institute standards of Pellet Fuels, effective October 27, 2010 (PFI 2010)

| Fuel property | Premium grade | Standard grade | Utility grade |

| Bulk density | 40.0–46.0 | 38.0–46.0 | 38.0–46.0 |

| Diameter (inches) | 0.230–0.285 | 0.230–0.285 | 0.230–0.285 |

| Diameter (mm) | 5.84–7.25 | 5.84–7.25 | 5.84–7.25 |

| Pellet durability index | ≥96.5 | ≥95.0 | ≥95.0 |

| Fines (percent at mill gate) | ≤1.0 | ≤1.00 | ≤1.00 |

| Inorganic ash percentage | ≤1.0 | ≤2.00 | ≤6.0 |

| Length (percentage > 1.5 inches) | ≤1.0 | ≤1.0 | ≤1.0 |

| Moisture percentage (wet basis) | ≤6.0 | ≤10.0 | ≤10.0 |

| Chloride (parts per million) | ≤300 | ≤300 | ≤300 |

5.Prospects for biomass wood fuel pellets

From the view of global market, the demand for wood pellets is keep increasing all these years. The pellet fuel production has reached 12 million metric tons every year since 2009. And the number is predicted to increase to 100 million by 2020. Environment situation, global agreements (support of renewable sources of energy) and government policies are all the dives for this trend.

Compared with 2010, the global energy consumption will grow 50% by the year 2035. At present, coal, oil and natural gas are the top three energy sources in the world. And 86% of the world's energy is supplied by these three traditional sources. However, there are also many new types of renewable energy are discovered and put to use, such as biomass energy, tidal and wave, solar, wind, geothermal and hydroelectric. It is projected that the renewable energy will take 15% of global energy consumption (100 quadrillion British Thermal Units (BTU)) by 2035.

6.10-20TPH big capacity complete wood pellet production line price

The cost of 10-20 ton per hour turn-key biomass wood pellet manufacutring plant project is usually between 600000USD-1500000USD.

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy