How to make animal powder feeds and pellet feeds in Uzbekistan?

(1)1-100TPH Animal mash feed manufacturing process in Uzbekistan feed making line

Procees Flow:Cleaning -- Crushing -- Mixing -- Packing

Generally,we can divide the raw materials into two parts:one need to be crushed,the other need not.So when we feed material to the feed production line,we will first separately feed them to different channels: particle materials go through feeding port to the feed grinder,mash materials go through feeding port to the feed mixing machine directly.

Usually,there are impurities in the particle material,so they will first be put into the pre-cleaner to remove the stones,clods and ropes etc. from them,and the go to the permanent magnetic tube to remove the iron part.The Cleaning system will help you to get the clean material and ensure that there's no unexpected impurities to damage the following feed processing equipment.

All cleaned materials will be stored and discharged in the bin for the hammer mill.As the hammer mill is the key machine of crushing system.Evenly mix different materials into complete mash feed.All materials are mixed together in the animal feed mixer.

Usually the volume of the bin for mixer,mixer and the buffer bin are all the same to ensure the mixer can work continuously batch after batch.

Please note that the you must make sure the materials every batch in the mixer are accurate to your formula(so you have to weigh the material every batch before feed them to the feeding port.).

If it is OK for your budget,you can change for automatic production line to let the computers do this.Premix feed are delivered into the mixer directly because of the small quantity and accurate requirement.

Mash feed(or powder feed) after mixing can be called complete feed now.If you want only to make mash feed,you can send them to the product bin to be packed.

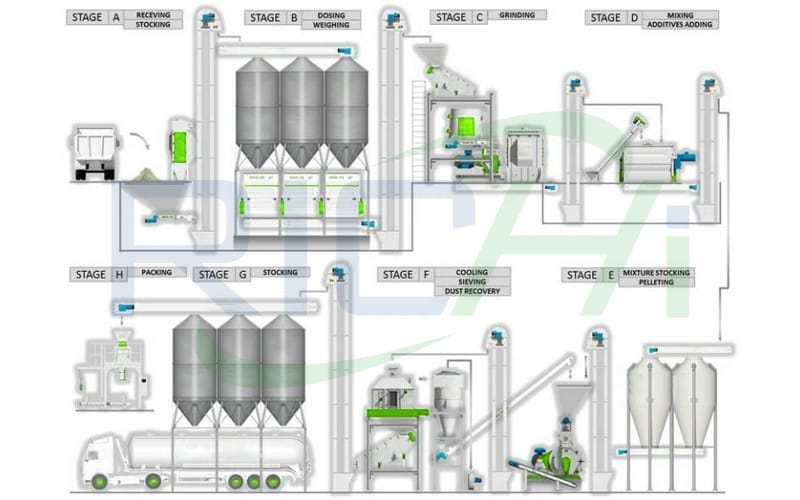

(2)1-100TPH Animal feed pellet produciton process in Uzbekistan feed mill plant

Procees Flow:Cleaning -- Crushing -- Mixing -- Pelleting -- Cooling -- Packing

For pellet feed,the mash feed will go to the following feed making machine.Animal feed pelleting machine will form the mash feed into pellet feed.Usually we use ring die pellet mill for feed production line,by changing different ring dies of the animal feed pellet milling machine we can make pellets of different sizes for different animals.

As we have add steam to the pellet mill,the pellet out from the pellet mill will be about 80℃,moisture 15%-16%,not suitable to pack,so we need to cool them.

Fan,cyclone,airlock and necessary pipes form a system to provide airflow for the counter-flow cooler,pellet feed will be cooled in the cooler and discharged. After cooling,the temperature of the pellet will be about 2-3℃ above the room temperature and with 13% moisture more or less.

Usually we will add crumble under the cooler.If we are to make small pellet,directly making it from the pellet mill will reduce the capacity of the whole plant and cost more energy,we can first make bigger pellet and then send it to crumble to make it smaller.