FAQs on pellet making machine, pellet mill, or other related equipment. Common problems when using the pellet machine and how to solve it.

Organic chicken feeds must not use chemically synthesized drugs, growth promoters and other chemically synthesized additives in their products, and are not allowed to use products obtained by genetic engineering techniques, such as genetically modified soybean meal, cottonseed meal, etc. Regulations and certification to allow the use of organic product marks on product packaging. The requirements of these products are higher than green feed. Only feeds that meet the above conditions or meet the above requirements can be called organic chicken feeds, otherwise they are not organic chicken feeds.

How to make organic chicken feed pellets?

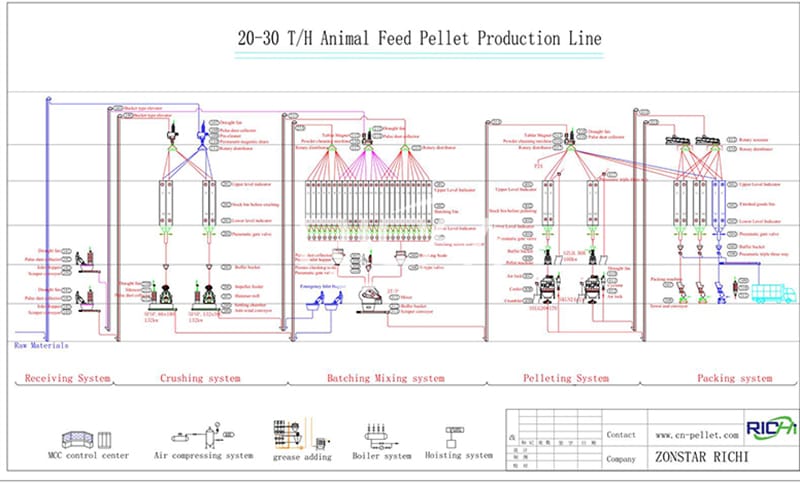

1.Complete poultry chicken feed pellet manufacturing plant process:

(1)Material Receive System

Easy to operate,every inlet has one impulse dust collector,keep environment clean,protect workers healthy.

(2)Crushing System

Pre-cleaner clean raw material ,then after magnet separator,storage bin and feeder,material goes into crusher to become powder.

(3)Batching & Mixing System

After crushing,original powder and some premix will be weighed in batching scale according to proportional,then go down to mixer to reach uniformity.

(4)Pelleting&Cooling System

After using high temperature steam to make raw material curing, the materials will be made to pellet through pellet press machine. Then the pellet will be cooled down by cooler.

(5)Packing System

The finish product contain pellet of normal size,smaller size and bigger size.By use grading sieve,we can get normal size pellet.

(6)Plant Control system

PLC is designed as per the requirement of the customer. It can also control automation level.

2.Chicken Feed machine

(1)Cleaning Machine

To ensure GMP cleaning is an important aspect. Different type of cleaner used for this purpose.

(2)Grinding machine

Raw materials need to be grinded as 225 m/microne perticle size for different type of feed.

(3)Mixing machine

Different R/M are mixed here with additives, oil/fat, medicines, etc. Good mixer ensure good quality.

(4)Pelleting machine

Produce final chicken pellet feed. A good pellet means "A complete feed" and a good chicken feed pellet mill can ensure that.

(5)Cooling machine

Extruded feeds are about 70-90°C. Cooler bring down it at normal temperature (+4° max).

(6)Screening machine

To ensure supply of quality and perfect size feed, screener plays a vital role. Uneven sizes screaned-out.

(7)Bagging machine

Ready feed need to be packed. It can be manual or automatic bagging depends on requirement.

(8)Conveying machine

All transportations like bucket elevator, screw & chain conveyor etc. for conveying RM & Finished goods.

Are you looking for popular wholesale price small plant organic chicken feed pellet production line,chicken forage pellet production line,high capacity automatic chicken feed pellet production line machine,full automatic chicken feed pellet production line with CE,chicken poultry feed line for pellet?Contact Richi Machinery.

Richi Machinery is able to provide complete chicken feed production line solutions, including total planning, civil engineering, steel construction, storage system, organic feed processing machinery, intelligent packing, electrical control system. Richi has engaged in feed machine for 25 years and thus has rich experience on feed machinery after repeated attempts and trials.

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy