FAQs on pellet making machine, pellet mill, or other related equipment. Common problems when using the pellet machine and how to solve it.

Feed is an indispensable part of the breeding process. Nowadays, as the price of feed products continues to rise, more and more farmers have begun to choose to prepare their own broiler feed. Scientific and practical broiler feed formulas and detailed feed preparation methods for broiler farmers can help improve the breeding efficiency and ensure the healthy growth of chickens. Therefore, whether it is a senior farmer or a person in the field of agriculture, this will be an essential professional knowledge. The following Richi Machinery introduces broiler feed formulation and broiler feed preparation to you in detail.

The nutritional requirements of broilers vary at different growth stages and at different ages. For example, from starter to six weeks of age, broilers require a high-protein, moderate-energy feed to support rapid growth. A typical starter-age formula might include 55 percent corn, 20 percent soybean meal, 3 percent fish meal, and essential vitamins and minerals. All ingredients should be finely ground and evenly mixed to ensure that each bite of feed contains a balanced amount of the required nutrients.

1. Broiler feed formula

(1) Feed formula of broiler chicks

a. Corn 55.3%, soybean meal 38%, calcium hydrogen phosphate 1.4%, stone powder 1%,salt 0.3%, oil 3%, additives 1%.

b. Corn 54.2%, soybean meal 34%, rapeseed meal 5%, dicalcium phosphate 1.5%, stone powder 1%, salt 0.3%, oil 3%, additives 1%.

c. Corn 55.2%, soybean meal 32%, fish meal 2%, vegetable meal 4%, calcium hydrogen phosphate 1.5%, stone powder 1%,salt 0.3%, oil 3%, additives 1%.

(2) Feed formula of chicken in meat

a. Corn 58.2%, soybean meal 35%, calcium hydrogen phosphate 1.4%, stone powder 1.1%,salt 0.3%, oil 3%, additives 1%.

b. Corn 57.2%, soybean meal 31.5%, rapeseed meal 5%, dicalcium phosphate 1.3%, stone powder 1.2%, salt 0.3%, oil 2.5%, additives 1%.

c. Corn 57.7%, soybean meal 27%, fish meal 2%, vegetable meal 4%, cotton meal 3%, calcium hydrogen phosphate 1.3%, stone powder 1.2%, salt 0.3%, oil 2.5%, additives 1%.

(3) Feed formula of meat chicken

a. Corn 60.2%, wheat bran 3%, soybean meal 30%, calcium hydrogen phosphate 1.3%, stone powder 1.2%, salt 0.3%, oil 3%, additives 1%.

b. Corn 59.2%, wheat bran 2%, soybean meal 22.5%, vegetable meal 9.5%, calcium hydrogen phosphate 1.3%, stone powder 1.2%, salt 0.3%, oil 3%, additives 1%.

c. Corn 60.7%, soybean meal 21%, fish meal 2%, vegetable meal 4.5%, cotton meal 5%, calcium hydrogen phosphate 1.3%, stone powder 1.2%, salt 0.3%, oil 3%, additives 1%.

3. How to process broiler pellet feed and broiler powder feed?

(1)If you want to make chicken mash feed, the manufacturing process: Cleaning -- Crushing -- Mixing -- Packing

Generally,we can divide the raw materials into two parts:one need to be crushed,the other need not.So when we feed material to the feed production line,we will first separately feed them to different channels: particle materials go through feeding port to the feed grinder,mash materials go through feeding port to the feed mixer directly.Usually,there are impurities in the particle material,so they will first be put into the pre-cleaner to remove the stones,clods and ropes etc. from them,and the go to the permanent magnetic tube to remove the iron part.

The Cleaning system will help you to get the clean material and ensure that there's no unexpected impurities to damage the following feed equipment.All cleaned materials will be stored and discharged in the bin for the hammer mill.

As the hammer mill is the key machine of crushing system.Evenly mix different materials into complete mash feed.All materials are mixed together in the feed mixer.Usually the volume of the bin for mixer,mixer and the buffer bin are all the same to ensure the mixer can work continuously batch after batch.

Please note that the you must make sure the materials every batch in the mixer are accurate to your formula(so you have to weigh the material every batch before feed them to the feeding port.).If it is OK for your budget,you can change for automatic production line to let the computers do this.Premix feed are delivered into the mixer directly because of the small quantity and accurate requirement.Mash feed(or powder feed) after mixing can be called complete feed now.If you want only to make mash feed,you can send them to the product bin to be packed.

(2)If you want to make pellet feed, the manufacturing process: Cleaning -- Crushing -- Mixing -- Pelleting -- Cooling -- Packing

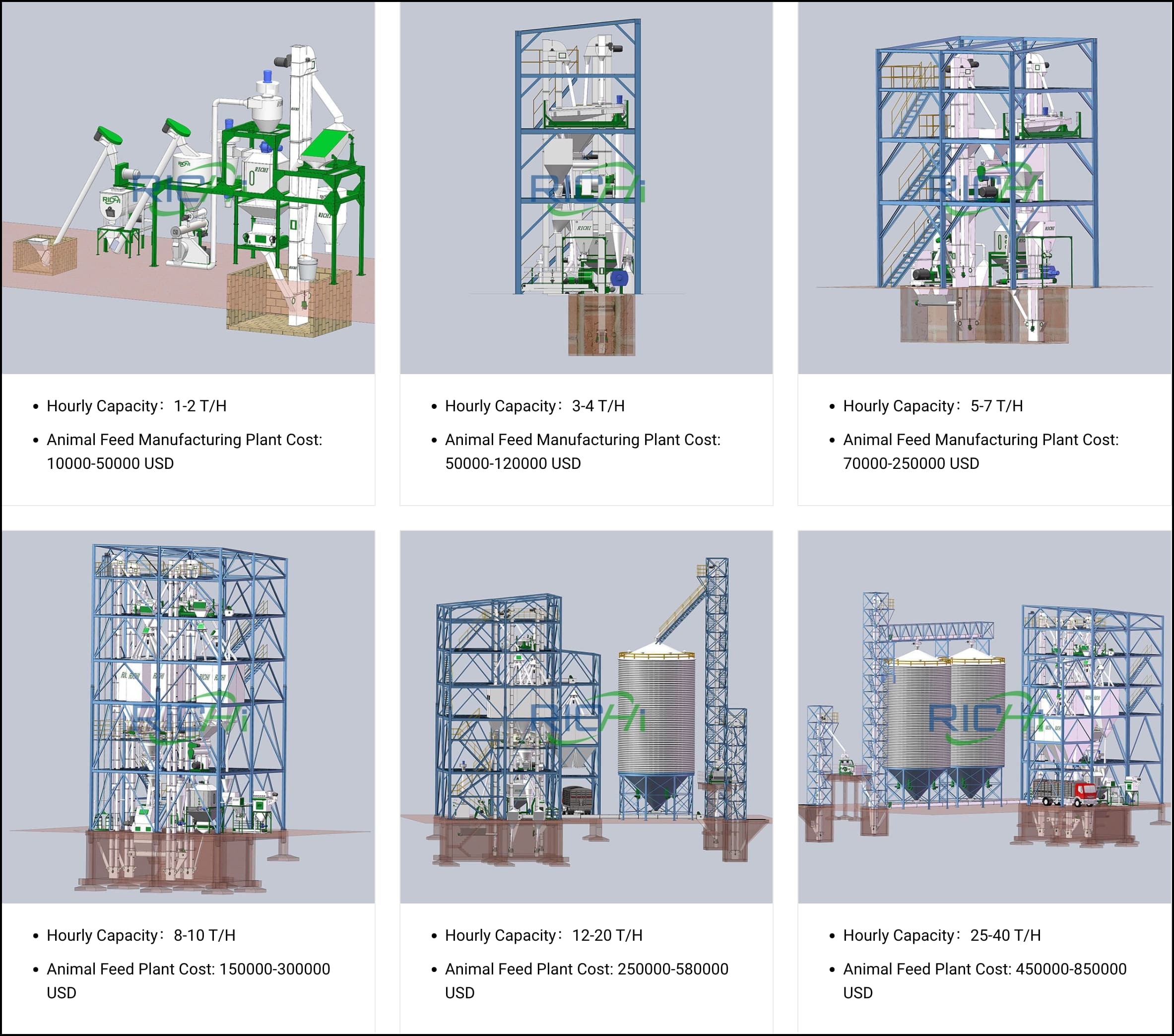

The following is the process diagram of RICHI Machinery’s complete feed pellet production line:

2. Problems needing attention in the preparation of broiler feed:

The cost of broiler feed accounts for about 80% of the feeding cost. The rationality of the preparation of broiler feed not only directly determines the growth rate of broiler but also affects the feeding efficiency, so the following points should be strictly followed when preparing broiler feed:

(1) Formulating

When formulating feed formulas, it is necessary to base on local feed materials, and to choose raw materials with sufficient resources, good palatability, rich nutrition, low prices, and non-toxic materials, and to greatly reduce feed costs under the premise of a certain nutritional value.

(2) Purchase of raw materials

When buying raw materials, you should pay attention to buying high-quality raw materials with high purity, fresh and free from impurities, and no moldy deterioration from large-scale and reputable stores. High-quality feed can not only provide rich nutrients for broilers, reduce the occurrence of diseases, but also create higher feeding benefits.

(3) Storage of raw materials

Feed materials should be stored in a dedicated raw material storage room, and the storage location should be dry, well ventilated, fresh air, and free of pollution. Feed materials should be protected from mold and deterioration during storage, to prevent expiration and expiration, to prevent contamination and stealing by rats, beasts and wild birds.

(4) Feed preparation

The feed should be accurately weighed in strict accordance with the types and proportions of raw materials specified in the feed formula, neither more nor less, more waste, and less nutrition. Additives can be added to a small amount of feed first, and then more feeds are added one by one. Various feeds and additives should be stirred evenly.

The above content is a detailed introduction to broiler feed formulation and broiler feed preparation. Feed factories and chicken farms must have an understanding of the above knowledge, so that feeds that meet the needs of broilers can be formulated to reduce breeding costs.

For chicken broiler pellet feed,the broiler mash feed will go to the following animal poultry chicken broiler feed pellet machine.Chicken feed pellet mill machine will form the mash feed into pellet feed.

Usually we use high quality ring die pellet mill for chicken feed production line,by changing different ring dies of the pellet mill we can make pellets of different sizes for different animals.As we have add steam to the poultry chicken feed pellet mill,the pellet out from the pellet mill will be about 80℃,moisture 15%-16%,not suitable to pack,so we need to cool them.

Fan,cyclone,airlock and necessary pipes form a system to provide airflow for the counter-flow cooler,pellet feed will be cooled in the cooler and discharged. After cooling,the temperature of the pellet will be about 2-3℃ above the room temperature and with 13% moisture more or less.Usually we will add crumble under the cooler.If we are to make small pellet,directly making it from the pellet mill will reduce the capacity of the whole plant and cost more energy,we can first make bigger pellet and then send it to crumble to make it smaller.

Some typical poultry chicken broiler animal feed pellet making plant projects:

Afghanistan 10T/H chicken poultry feed manufacturing plant

Uzbekistan 15 tons per hour poultry animal feed processing plant

...

You can directly consult Richi Machinery for more questions about"high quality chicken feed pellet making plant"" how to make chicken feed for layers by chicken feed equipment"" poultry chicken mash feed mill machinery""advanced small poultry feed mill price""ring die poultry feed mill equipment",Email: enquiry@cn-pellet.com,Whatsapp/Cel: +86 185 7410 3366

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy