Whether you are producing animal feed pellets or biomass pellets, before pelletizing, your feed formulation (grains, soybean meal, oil meal, grasses, etc.) and biomass raw materials (crop straw, wood processing waste, industrial organic waste, municipal solid organic waste, etc.) need to be pre-processed and treated to become a powder suitable for pelletizing. This process usually consists of chipping, crushing, drying, mixing and other procedures.

01

Log pelletizing pre-stage processing equipment, the necessary equipment for

slicing large-size raw materials such as logs.

02

Widely used for raw material crushing in animal feed or biomass pellet processing

enterprises, which can crush the raw material to about 5mm for

pelletizing.

03

he body is slightly tilted so that the discharge end is lower than the feed end

to transport material through the dryer under the force of gravity.

04

Necessary equipment for animal feed production, which can fully mix raw materials evenly, and greatly help the consistency and nutritional balance.

learn more →

Pelletizing is a process whereby treated raw materials are processed into tight, uniformly sized cylindrical pellets. Of course different applications require different pellet sizes. With the quick release device you can easily change the pelletizer ring die for the production of different pellet sizes. Before changing it is recommended to talk to a technician or contact us directly.

After processing at high temperatures and pressures, the temperature of the freshly produced pellets is so high that they require further processing before they can be packaged and stored for use.

01

The pellet cooling equipment cools the newly produced pellets that have undergone high temperature and high pressure to room temperature so that the pellets can be better stored.

learn more →02

Filter out unqualified particles or powders from the pellet production

process. These materials can be reintroduced into the granulator for

granulation.

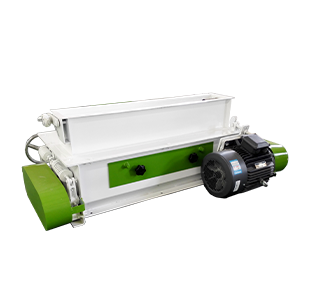

03

The crumbler adopts the principle of the differential speed of the roller to extrude and shear the incoming material, so that the large granular material is broken into irregular ...

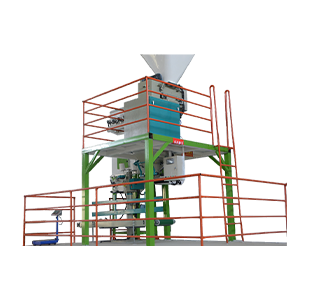

learn more →04

Consists of a finished storage bin and weighing system for packaging finished

feed pellets.

The complete pellet production process does not only depend on the above equipment, but also on the following auxiliary equipment, which often plays a vital role in keeping the pellet production line running smoothly and the quality of the pellets produced.

Each equipment in the production line, especially the main equipment, after a long time of operation, whether it is maintenance or repair, some parts contacting the material, there will be wear and tear, which will directly or indirectly lead to the occurrence of a variety of production problems. Therefore, when your pellet plant runs for a period of time, we recommend contacting the after-sales department to inquire about accessories and spare parts replacement.

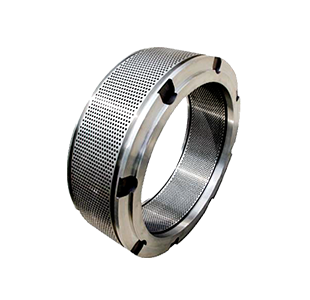

01

The ring die enhances pellet production efficiency and durability by providing consistent pressure and minimal wear.

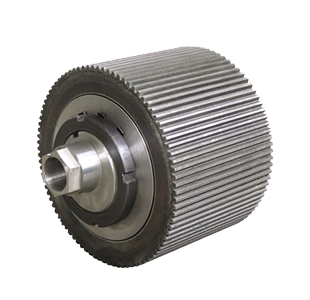

02

The pressure roller ensures uniform compression of materials, resulting in evenly formed pellets.

03

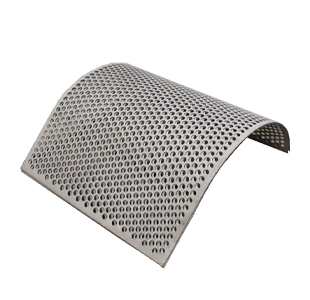

The screen allows for precise control over particle size, ensuring consistent quality in the final product.

04

The hammer effectively reduces raw material size, making it easier to process for various applications.

“Discover how RICHI combines the above equipment into a complete pellet production line.”

Contact Us

RICHI Machinery guarantees top-grade equipment built to rigorous quality standards.

Comprehensive warranties provide peace of mind and protect your investment.

Dedicated customer support assists clients through every stage of their project.

Secure payment options ensure customer confidence and transaction safety.

Reliable global logistics ensure timely delivery, no matter your location.

Note: Pellet production is a continuous and complex process, requiring many equipment to complete the production from raw materials to finished pellets. Therefore, it is suitable for commercial projects but not for personal use.

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy