Frequency conversion feeding system, steam tempering system, double pressure roller pelletizing system, Siemens electronic control system, plus alloy steel forging body, these become the core of animal feed pellet production.

Brand

RICHI

Capacity

10 Ton Per Hour

Application

Animal

Finished

Pellets

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

|---|---|---|---|---|---|---|---|---|

| Main Motor Power(Kw) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder Power(kw) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Conditioner Power(kw) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Ring Die Inner Diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 |

| Finished Pellets Diameter (mm) | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 |

| Production Output (TPH) | 1.0-1.5 | 3-4 | 5-6 | 10-12 | 15-16 | 20-22 | 30-33 | 38-40 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of animal feed production.

Feeding and conditioning systems

The optimized conditioning system with inverter feeding system improves the safety, nutritional value and maturation of the raw material to a great extent. This improves the overall quality of the feed from the source and ensures healthy feeding.

Drive system

High-end Siemens industrial grade drive motor drives the drive shaft of RICHI animal feed pellet mill, which is more stable and durable than traditional belt drive. In the long run, this not only improves efficiency but also saves maintenance costs.

Structure and material

The body of the machine is made of high quality and high specification alloy steel, which is sturdy and durable, reduces resonance and runs stably. The parts that come into contact with the raw material are made of high grade stainless steel, which does not affect the raw material in any way and greatly improves corrosion resistance.

Control and Safety

Each feed pellet mill is equipped with an independent electric control system and safety stop function. It can not only avoid losses caused by perceived errors, but also effectively protect the pellet mill and subsequent production equipment.

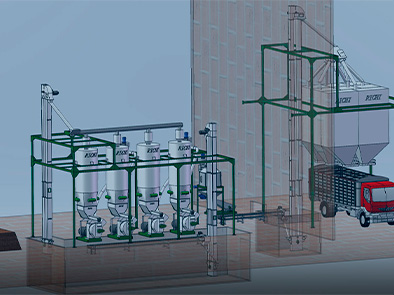

Discover our streamlined buying process that makes it simple and efficient for you to get a complete animal feed pellet mill plant. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

HENAN RICHI MACHINERY CO.,LTD

Henan Richi Machinery Co., Ltd was founded in 1995. After nearly thirty years of development and expansion, RICHI Machinery has grown into a modern enterprise covering an area of 60,000 square meters and integrating independent research and development, production and sales.

The products involve feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveying equipment and engineering, steel structure engineering, silo, automation control technology and engineering, etc., and each product series has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

The system is fully automated and requires minimal labor. Customized pellet production solutions can be switched at the touch of a button in the control room for pelletizing a wide range of raw materials.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of animal feed plant do you want to establish?

How many tons per hour about this plant you want to build?

Where is this animal feed plant going to be built?

When do you plan to start the operation?

Definitely. The 10TPH feed pellet making machine is built for high-volume feed production—that’s about 80 to 100 tons per day if you run two shifts. It’s ideal for medium to large commercial feed plants, integrated farms, or companies supplying feed to multiple livestock operations. One customer in Colombia uses it to feed thousands of cattle and sells the extra to neighboring ranches. It’s not an overkill—it’s a smart investment if you're producing at serious scale and want consistency, power, and durability.

Yes, and that’s one of the machine’s biggest strengths. It comes equipped with a forced feeder, which solves a common issue with fibrous or light materials like hay, straw, or alfalfa. Most regular pellet mills struggle with this, but this model feeds the material evenly without clogging. So whether you’re working with grass silage, dry hay, or mixed alfalfa, this machine presses it into durable pellets. In South Africa, a client mixes 50% chopped hay with grain and makes beautiful cattle feed with no problem

Absolutely. It’s a multi-purpose animal feed pellet mill. You can use it to produce feed for broilers, layers, pigs, cattle, goats, sheep, and more. All you need is a good formulation and the right die size. Some of our customers run chicken feed in the morning, clean the machine, and switch to ruminant feed with grass in the afternoon. It’s like one machine with many personalities. We’ll even help you design the formulas for your region and animals.

The biggest advantage is output + flexibility. The 10TPH feed pellet machine can handle much more volume, which means lower cost per ton, faster turnaround, and the ability to take on larger contracts or more customers. But beyond that, it can also handle more complex raw materials—especially grass-containing formulas—thanks to its forced feeder. So if you’re thinking about feed for cattle, sheep, goats, or planning to go semi-industrial, this machine gives you room to grow without limits.

For a full feed production line built around the 10TPH feed pellet making machine, we recommend 300–500 square meters, depending on how much storage and automation you want. The line typically includes a crusher, mixer, pellet mill, cooler, screener, bagging station, and sometimes bulk silos or conveyors. We’ve installed similar setups in tight workshops and larger industrial zones. In Thailand, one client fit a full 10tph line into a converted warehouse using a smart U-shaped layout. We’ll help you optimize your space, no matter the size.

It handles a wide range of raw materials: corn, soybean meal, wheat bran, rice husk, cassava flour, cottonseed cake, grass powder, alfalfa meal, and more. For grass, we recommend chopping or crushing it first, so it flows better into the feeder. A customer in Argentina uses alfalfa plus maize bran, and the pellets come out beautifully with strong density and minimal fines. As long as your materials are dry, ground, and properly mixed, this machine can process them like a champ.

The feed pellet machine price for a 10tph system is higher than smaller models, of course—but it's designed to pay for itself fast. You’re getting a commercial-grade machine with top performance, long service life, and support for complex formulas. In places like Nigeria and Brazil, customers often recover the cost within 18 to 24 months, especially if they’re producing for both their own farm and outside sales. It’s a serious machine for serious business, and we help you make every dollar count.

Yes, and we’d even say it’s built for that job. The forced feeder and large feed port make this model ideal as a hay pellet machine or alfalfa pellet making machine. In Morocco, a dairy farm uses chopped alfalfa and molasses to produce their own nutrient-rich cattle pellets. The pellets are dense, store well, and reduce waste. If you’re looking to convert dry forage into convenient, high-quality feed, this machine will do the job reliably.

Not at all. With 2–3 trained operators, you can run the whole line smoothly. We offer full training during installation, plus simple manuals, video guides, and ongoing WhatsApp support. Operators need to understand basic mechanics—feeding the machine, checking for blockages, adjusting moisture—but it’s not complicated. We’ve worked with village co-ops, farms, and family-run businesses who had no prior experience, and they’re now producing 80+ tons a day with no issues.

When you choose us, you’re getting more than just an animal feed pellet machine for sale—you’re getting our full support network. That includes:

Whether you're in Tanzania, Indonesia, or the USA, we stick with you long after delivery. It’s not just a sale—it’s a long-term relationship built on trust.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy