Frequency conversion feeding system, steam tempering system, double pressure roller pelletizing system, Siemens electronic control system, plus alloy steel forging body, these become the core of animal feed pellet production.

Brand

RICHI

Capacity

5 Ton Per Hour

Application

Animal

Finished

Pellets

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

|---|---|---|---|---|---|---|---|---|

| Main Motor Power(Kw) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder Power(kw) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Conditioner Power(kw) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Ring Die Inner Diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 |

| Finished Pellets Diameter (mm) | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 |

| Production Output (TPH) | 1.0-1.5 | 3-4 | 5-6 | 10-12 | 15-16 | 20-22 | 30-33 | 38-40 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of animal feed production.

Feeding and conditioning systems

The optimized conditioning system with inverter feeding system improves the safety, nutritional value and maturation of the raw material to a great extent. This improves the overall quality of the feed from the source and ensures healthy feeding.

Drive system

High-end Siemens industrial grade drive motor drives the drive shaft of RICHI animal feed pellet mill, which is more stable and durable than traditional belt drive. In the long run, this not only improves efficiency but also saves maintenance costs.

Structure and material

The body of the machine is made of high quality and high specification alloy steel, which is sturdy and durable, reduces resonance and runs stably. The parts that come into contact with the raw material are made of high grade stainless steel, which does not affect the raw material in any way and greatly improves corrosion resistance.

Control and Safety

Each feed pellet mill is equipped with an independent electric control system and safety stop function. It can not only avoid losses caused by perceived errors, but also effectively protect the pellet mill and subsequent production equipment.

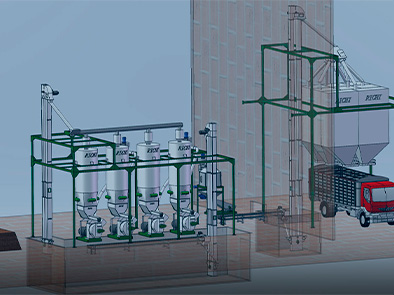

Discover our streamlined buying process that makes it simple and efficient for you to get a complete animal feed pellet mill plant. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

HENAN RICHI MACHINERY CO.,LTD

Henan Richi Machinery Co., Ltd was founded in 1995. After nearly thirty years of development and expansion, RICHI Machinery has grown into a modern enterprise covering an area of 60,000 square meters and integrating independent research and development, production and sales.

The products involve feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveying equipment and engineering, steel structure engineering, silo, automation control technology and engineering, etc., and each product series has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

The system is fully automated and requires minimal labor. Customized pellet production solutions can be switched at the touch of a button in the control room for pelletizing a wide range of raw materials.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of animal feed plant do you want to establish?

How many tons per hour about this plant you want to build?

Where is this animal feed plant going to be built?

When do you plan to start the operation?

For most mid-sized operations, yes—it’s a sweet spot. With 5 tons per hour output, this machine can easily support 30–40 tons per day of production. That’s plenty for farms feeding 10,000+ birds, or even selling to other nearby farms. We’ve got customers in Colombia, Indonesia, and Nigeria using the 5tph feed pellet mill to supply feed not just for their own animals, but also to neighboring farmers. If you're not going industrial yet but want more than a "backyard" setup, this model hits the mark.

Absolutely. It’s a true multi-purpose feed pellet machine. Whether you’re making broiler feed, layer mash, cattle feed, or pig grower pellets, the 5tph feed pellet making machine handles it all. All you need to do is adjust the die size and formulation. In Vietnam, one customer runs chicken feed during the week and switches to cattle feed production on weekends. It’s like one machine, many feed types—a real asset for farmers who want flexibility.

For a complete line (crusher, mixer, pellet mill, cooler, bagging), you’ll want around 150–250 square meters. We’ve seen it set up in small factories, old rice mills, and even custom steel sheds. In Africa, one customer built a two-room block: one for raw materials, one for processing. It doesn’t have to be fancy—it just needs to be clean, dry, and well-ventilated. We’ll send you a layout plan based on your available space so you don’t waste time or square footage.

Not at all. Most of our customers are first-timers, and we train them step by step. Once installed, running the 5tph feed pellet machine is like learning to drive a tractor—there’s a bit of learning, but once you’ve got it, it becomes second nature. We provide on-site guidance, WhatsApp support, and even video tutorials. Operators in Ghana, the Philippines, and Ecuador picked it up in just 1–2 days. If you can manage a basic motor and understand simple controls, you’re good to go.

You can use all kinds of locally available feed ingredients—corn, soybean meal, wheat bran, rice husk, cassava flour, fishmeal, sunflower cake, you name it. The pellet mill animal feed system works best with a well-ground and mixed formula, which we help you design based on your animals and region. A customer in Peru uses maize, rice bran, and fishmeal to make broiler feed, while one in Uganda mixes cottonseed cake and cassava for cattle pellets. No imports needed—local feed, local success.

Great question. The feed pellet machine price for a 5tph model depends on whether you want just the machine or a full production line. But compared to the daily cost of buying ready-made feed, most of our customers say it’s absolutely worth it. A farmer in Kenya told us, “This machine paid for itself in 14 months.” Plus, with our support and proper maintenance, it can last 10 years or more. It’s a smart mid-range investment for serious players who want control over quality and costs.

100%. This model is very popular with small feed businesses who make and sell custom poultry or cattle feed. It gives you the volume to handle customer orders but doesn’t require the massive investment of an industrial line. A customer in South Africa started with one 5tph poultry feed pellet machine and now supplies four farms with regular weekly orders. It’s fast, efficient, and the pellet quality is good enough to build a brand. If you’re looking to launch a feed brand, this machine is a strong start.

Most maintenance is simple and can be done by your team—greasing the bearings, checking the rollers and dies, cleaning the feeder, etc. We provide a maintenance checklist and spare parts list. You don’t need to be an engineer—we’ve trained teams of just 2–3 workers to manage the whole system. Parts like the ring die and rollers will need replacing after heavy use, but that’s expected. And if something goes wrong, we’ll troubleshoot with you remotely or help arrange local service.

When you buy from us, you get more than a machine—you get a full support system. That includes:

We’ve supported customers in rural Bolivia, coastal Nigeria, and the backroads of Myanmar—if you’ve got an internet signal, we’re there for you.

The biggest advantage? Room to grow. With a 5tph feed pellet making machine, you don’t need to upgrade too soon. You can start producing for your own farm and sell the rest to local customers. If you go with a 1-ton model, you might outgrow it in a year and have to reinvest. Plus, bigger machines tend to have lower production cost per ton. One client in Bangladesh said moving straight to 5tph was “the best business decision” they made—because when demand hit, they were ready.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy