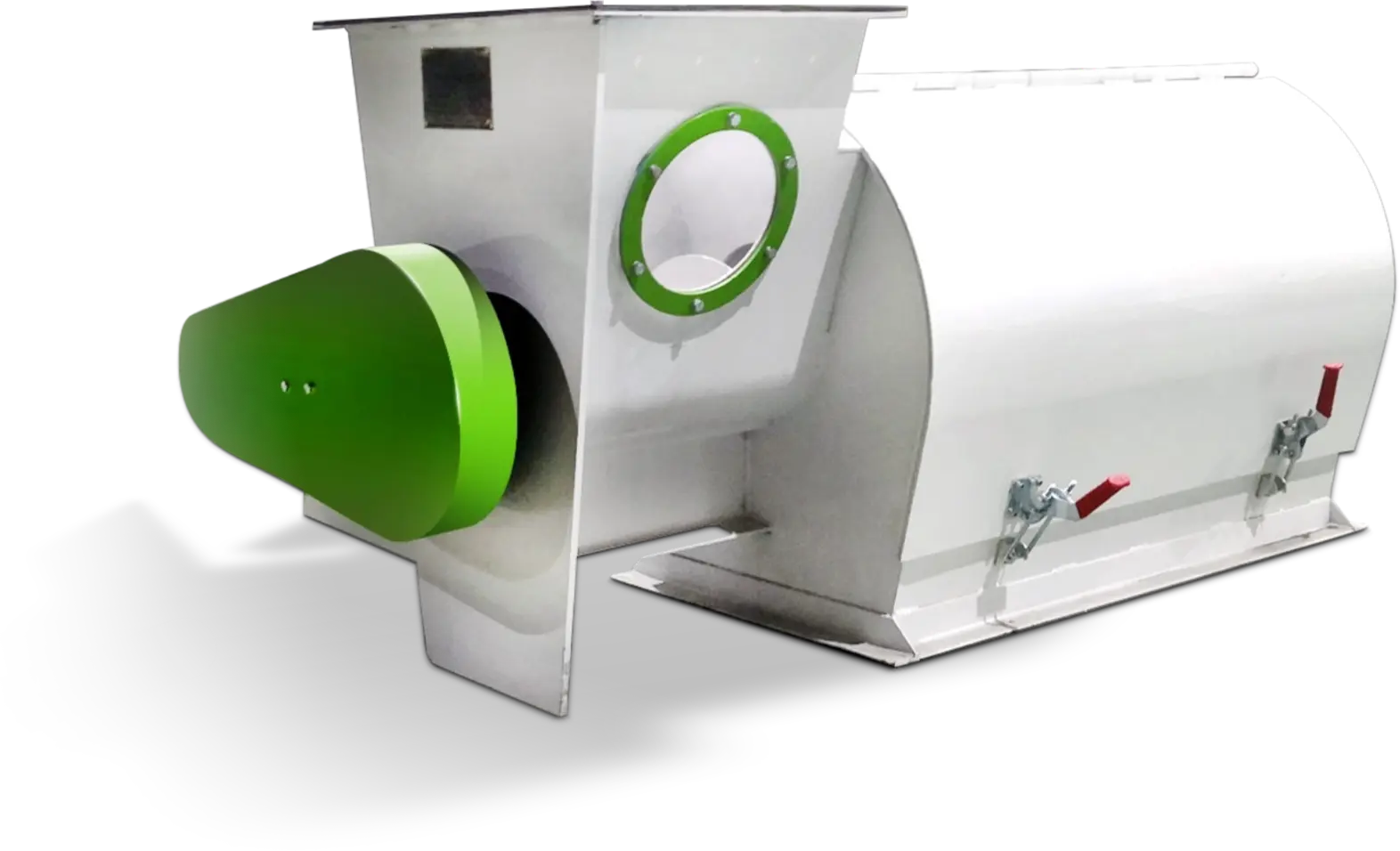

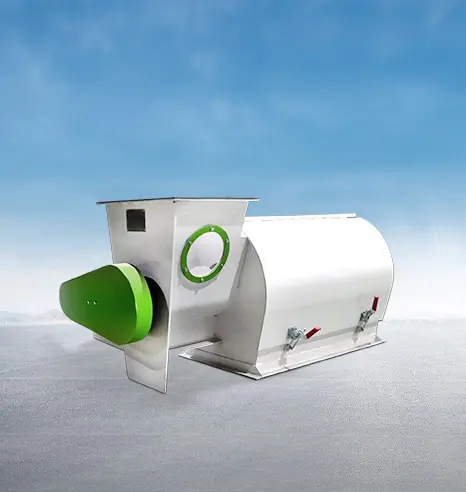

Efficient and smooth operation; compact and simple installation; easy maintenance and easy replacement of the screen drums; all these become excellent qualities to deal with all kinds of impurities in the powder part of the formulated raw materials. They are also essential for the cleaning phase of raw materials in animal feed production, together with pellet cleaning screens.

Brand

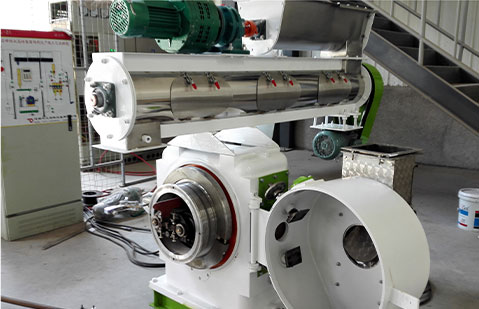

RICHI

Model

SCQZ

| Model | Power(kw) | Screen Diameter(mm) | Screen Inclination Angle | Capacity(TPH) | Removal Rate |

|---|---|---|---|---|---|

| SCQZ60*50*100 | 5.5 | φ16~φ30 (can be customized according to materials) | 3° | 10-15 | ≥95% |

| SCQZ90*80*110 | 7.5 | φ16~φ30 (can be customized according to materials) | 3° | 50-50 | ≥95% |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of your production.

Smooth Material Flow

The optimized feeding and discharge ports ensure a smooth and continuous flow of materials, minimizing blockages and reducing downtime. This contributes to a more efficient feed production process.

Adjustable and Flexible Design

The adjustable screen mesh allows for customization based on the type of raw material being processed. Operators can easily switch mesh sizes to handle different feed ingredients, making the equipment highly versatile.

Durability and Longevity

Constructed from high-quality, wear-resistant materials, the powder cleaning screen is designed to withstand heavy use in demanding production environments. The robust construction ensures a long lifespan and minimal maintenance requirements.

Protection for Downstream Equipment

By removing impurities early in the feed production process, the cleaning screen protects downstream equipment such as grinders and mixers from potential damage caused by foreign materials. This reduces repair costs and extends the life of other machinery in the production line.

Discover our streamlined buying process that makes it simple and efficient for you to get a complete pellet production line. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

Henan RICHI Machinery Co., Ltd

Henan Richi Machinery Co., Ltd was founded in 1995. After more than 20 years of development and growth, RICHI has grown into a modern enterprises engaged in independent research and development, production and sales, Including feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveyor equipment and engineering, steel structure engineering, silos, automation control technology and engineering product development and manufacturing, design and installation. The company has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

The system is fully automated, enabling seamless operation with minimal labor and supporting sustainable agricultural practices through the use of alfalfa and other forages. Of course you can also use other materials for pelletizing.

Learn More

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of pellet production line do you want to establish?

How many tons per hour about this line you want to build?

Where is this pellet production line going to be built?

When do you plan to start the operation?

The purpose of the powder cleaning sieve in animal feed production is to remove impurities such as stones, metal particles, and large debris from raw materials, ensuring that only clean and safe ingredients are used in the feed. This process enhances the quality of the final product and protects downstream equipment from potential damage.

The powder cleaning sieve improves feed quality by efficiently removing impurities such as stones, metal fragments, dust, and large debris from raw feed materials. This ensures that only clean, pure, and high-quality ingredients proceed to the next stages of production, resulting in safer and more nutritious feed for animals. Additionally, by eliminating contaminants, the sieve helps prevent potential damage to processing equipment, contributing to a smoother and more consistent feed production process.

The powder cleaning sieve can process a variety of raw materials commonly used in animal feed production, including:

The sieve is versatile, efficiently removing contaminants from these diverse materials to ensure optimal feed quality.

Yes, the screen mesh size of the powder cleaning sieve can be adjusted. This feature allows operators to customize the sieve for different types of raw materials, ensuring optimal impurity removal and achieving the desired level of cleanliness for various feed production needs.

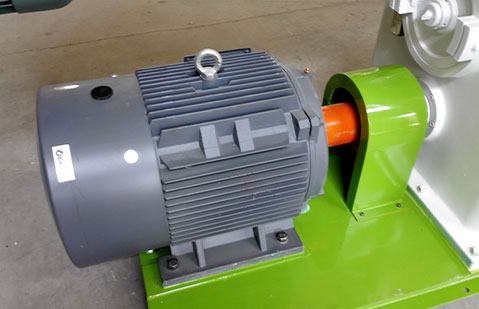

The vibrating mechanism in the powder cleaning sieve operates by generating continuous and controlled vibrations that move the screen mesh. These vibrations are typically created using an electric motor or an eccentric weight system. As the screen vibrates, raw materials fed into the sieve are agitated and spread across the mesh surface.

The movement forces fine particles to pass through the mesh, while larger impurities are carried to the discharge port for removal. This efficient vibrating action ensures thorough and rapid separation of unwanted materials from the raw feed ingredients, optimizing the cleaning process and maintaining a steady material flow.

The powder cleaning sieve is typically constructed from high-quality, wear-resistant materials, such as stainless steel for the screen mesh and contact parts, ensuring durability and resistance to corrosion. The frame and support structure are often made from reinforced steel or heavy-duty alloy, providing stability and reducing vibrations during operation. These materials are chosen to withstand the rigors of continuous use in feed production environments while maintaining easy maintenance and a long service life.

The powder cleaning sieve is typically constructed from high-quality, wear-resistant materials, such as stainless steel for the screen mesh and contact parts, ensuring durability and resistance to corrosion. The frame and support structure are often made from reinforced steel or heavy-duty alloy, providing stability and reducing vibrations during operation. These materials are chosen to withstand the rigors of continuous use in feed production environments while maintaining easy maintenance and a long service life.

Yes, the powder cleaning sieve plays a crucial role in protecting other equipment in the production line. By effectively removing impurities like stones, metal fragments, and large debris from the raw materials, the sieve prevents these contaminants from reaching downstream machinery, such as grinders, mixers, and pellet mills. This protection reduces the risk of damage, wear, and potential breakdowns, ultimately extending the lifespan of the equipment and lowering maintenance costs.

The powder cleaning sieve is designed with noise-reducing features, and the noise level typically ranges from 70 to 85 decibels during operation. This is comparable to the noise level of a vacuum cleaner or a busy office, making it manageable in most industrial settings. However, the exact noise level may vary depending on the model and installation environment.

The typical capacity of a powder cleaning sieve can vary significantly depending on the model and design. Generally, it ranges from 1 ton per hour for smaller models to 20 tons per hour or more for larger, industrial-scale units. The specific capacity needed will depend on the volume of raw materials being processed in your feed production line.

If you need further information, please contact us

Note: Pellet production is a continuous and complex process, requiring many equipment to complete the production from raw materials to finished pellets. Therefore, it is suitable for commercial projects but not for personal use.

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2026