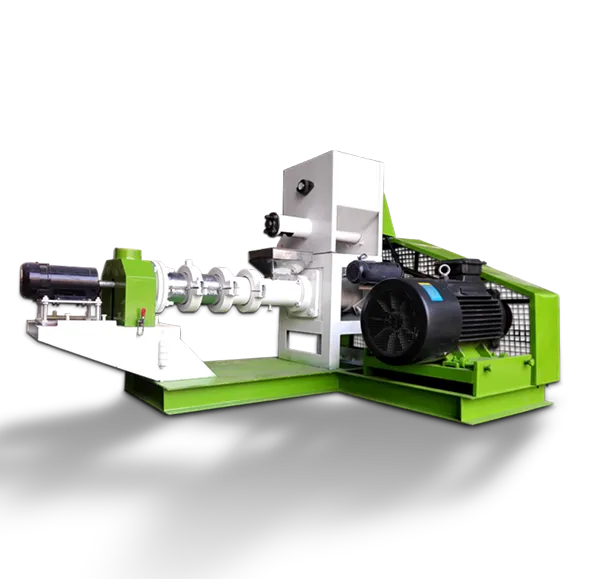

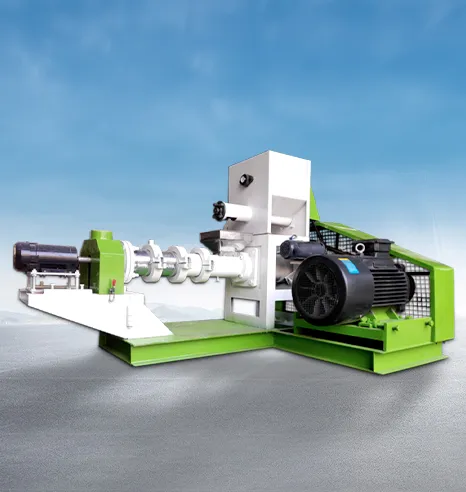

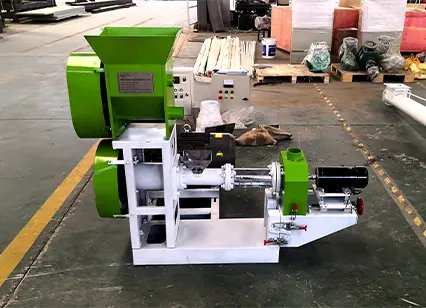

Inverter feed system with anti-clogging settings; the thicker and larger pre-conditioning zone for ingredients; the screw design for thorough mixing and expansion; the ability to set up adjustable molds of various sizes; together with Siemens motors providing a powerful and stable drive system; make the RICHI Machinery the first choice of equipment for aquafeed production.

Brand

RICHI

Application

Fish Feed

Finished

Extruded Pellets

| Model | Main Motor Power(Kw) | Feeder Power(Kw) | Cutting Power(Kw) | Screw Diameter(mm) | Overall Dimensions(mm) | Production Output(TPH) |

|---|---|---|---|---|---|---|

| DGP-90B | 37 | 0.75 | 0.55 | 90 | 2100*1450*1350 | 0.2-0.4 |

| DGP-120B | 55 | 2.2 | 1.1 | 120 | 2400*1950*1600 | 0.5-0.6 |

| DGP-160B | 90 | 3 | 1.5 | 160 | 3100*2650*1800 | 0.8-1.0 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of fish feed production.

Feeding & Extruding

The speed-regulating feeding device is convenient for operation and uniform feeding; the stepless variable speed soft knife cutting system realizes the production of products of any length and ensures the quality of products without burrs.

Design & Material

Novel and unique design, simple structure, easy to dismantle and install, easy to operate; screw sleeve and screw are made of special wear-resistant and high-temperature alloy steel material, molded by heat treatment, and the body is likewise made of high-specification alloy steel.

Control & Safety

Produces floating pellets of expanded feed that can float on the surface of the water for at least 12 hours without soaking. Maintains the nutrient content of the pellets and reduces the risk of water contamination.

Maintenance & Replacement

The simple structure is not only easy to maintain, but also easy to replace the discharge template, which requires different aperture feeds only need to replace the required aperture template. This not only greatly improves the diversity of aquatic feed pellet production, but also maximizes the return on investment.

Explore our efficient and streamlined purchasing process, designed to simplify and optimize the acquisition of a complete fish extruded feed production plant. Every stage is tailored to meet your specific requirements, from the initial schematic design and precise manufacturing processes to secure payment methods and seamless on-site installation and commissioning. Furthermore, our comprehensive spare parts service provides ongoing support and ensures optimal machine performance, offering you long-term reliability and peace of mind.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

HENAN RICHI MACHINERY CO.,LTD

Henan Richi Machinery Co., Ltd was founded in 1995. After nearly thirty years of development and expansion, RICHI Machinery has grown into a modern enterprise covering an area of 60,000 square meters and integrating independent research and development, production and sales.

The products involve feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveying equipment and engineering, steel structure engineering, silo, automation control technology and engineering, etc., and each product series has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

The system is fully automated, enabling seamless operation with minimal labor and supporting sustainable agricultural practices through the use of alfalfa and other forages.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of aquatic feed plant do you want to establish?

How many tons per hour about this plant you want to build?

Where will your aquatic feed mill plant be built?

When do you plan to start this project?

Good question—and one we hear often. A floating fish feed extruder uses high pressure and high temperature to puff up the feed and make it float on water. It’s different from regular pellet mills, which compress the feed but don’t give it that air-filled, buoyant structure. The extruder also cooks the feed as it processes, making it more digestible for fish. If you’re farming tilapia, catfish, koi, or other surface-feeding species, a floating feed extruder machine is the way to go.

The floating pellets are perfect for surface-feeding fish like:

If your fish come up to the top for food, this is the type of feed you want. Not only does it reduce waste (since uneaten feed is visible), but it also helps monitor fish health and appetite. In regions like Southeast Asia and South America, floating feed is becoming the industry standard.

Our DGP Series extruders are designed for small to medium-scale fish farmers or startups, with output ranging from 200 kg/h to 1000 kg/h. For example:

So whether you're feeding your own ponds or planning to supply a local market, there’s a size that fits. And if you grow, we help you scale up step-by-step.

Not at all. The floating fish feed extruder machine is designed with first-time users in mind. After installation, we train you or your operator to:

In places like Bangladesh and Peru, we’ve helped farmers and family-run businesses start production with zero technical background. Within a couple of days, most folks are comfortable running it on their own.

The beauty of this machine is flexibility. You can use a mix of:

Just make sure the ingredients are ground finely and mixed well before feeding into the machine. We’ll help you build a balanced formula based on the species you're farming and what’s available locally.

A basic floating fish feed production line includes:

We can help you build this step-by-step, so even if you're starting with just a grinder and extruder, you're on the right track.

Yes! When you produce buoyant feed pellets, just drop a few into a bucket of water. They should stay on the surface for at least 12–24 hours. If they sink quickly or break apart, you may need to adjust:

We’ll walk you through all this during training, and even send sample recipes. Our goal is to help you make pellets that not only float—but perform.

The small electric fish feed extruder machine price starts at just a few thousand dollars, depending on the model. It’s an affordable way to start your own feed business or stop relying on expensive commercial feed. If you’re running a small farm or looking to supply your neighbors, this is a great investment with low operating costs. Plus, we’ll give you a complete price breakdown with no hidden charges.

Yes—with a few adjustments. By modifying the moisture content, temperature, and screw speed, you can produce semi-floating or sinking feed. This is useful if you’re feeding species like catfish or shrimp that prefer feed at mid or bottom water levels. Some clients produce both floating and sinking pellets using the same machine—it’s all about fine-tuning. And we’ll teach you how to switch easily during training.

With RICHI, you’re never alone. After you purchase, we provide:

Whether you're in Vietnam, Colombia, Eastern Europe, or rural Kenya, we’ve got your back—from day one to year ten.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy