Achieve optimal feed quality with our high-performance hammer mill, designed for precise and efficient grinding. Perfect for producing fine, uniform feed particles for poultry, livestock, and aquaculture, ensuring improved animal nutrition and feed conversion.

Brand

RICHI

Model

SFSP

| Model | SFSP56*40 | SFSP66*60 | SFSP66*60 | SFSP66*80 | SFSP66*80 | SFSP66*80 | SFSP66*100 | SFSP66*100 | SFSP66*100 | SFSP66*120 | SFSP66*120 | SFSP66*120 | SFSP66*150 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rotor Dia.(mm) | 560 | 660 | 660 | 660 | 660 | 660 | 660 | 660 | 660 | 660 | 660 | 660 | 660 |

| Crushing Chamber Width(mm) | 400 | 600 | 600 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1200 | 1200 | 1200 | 1500 |

| Rotating Speed(mm) | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 |

| Line Speed of Hammers(m/s) | 88 | 103 | 103 | 103 | 103 | 103 | 103 | 103 | 103 | 103 | 103 | 103 | 103 |

| Power(kw) | 37 | 55 | 75 | 75 | 90 | 110 | 110 | 132 | 160 | 160 | 185 | 220 | 220 |

| Production Output(For Grain)(TPH) | 3-5 | 5-6 | 6-7 | / | 8-10 | 10-12 | / | 15-17 | 20-22 | / | 25-27 | 30-32 | 40-50 |

| Production Output(For Grass/Straw)(TPH) | 0.8-1.0 | 1.0-1.5 | / | 2.0-2.5 | / | / | 3.0-4.0 | / | / | / | 5.0-6.0 | / | 7.0-8.0 |

| Production Output(For Wood Chips)(TPH) | 0.5-0.6 | 1.0-1.2 | / | / | 2.0-2.5 | / | / | 3.0-4.0 | / | / | 4.0-5.0 | 5.0-6.0 | 7.0-8.0 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of your production.

Intelligent Control System

Features real-time monitoring and automated adjustments for feed rate and grinding speed.

Energy Optimization

Equipped with the latest models of high-specification Siemens motors, every machine is stable and continuously running.

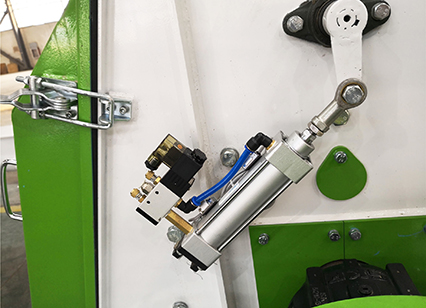

Security Apparatus

Travel switches maximize the safety of the equipment and the operator. In the event of a problem, power is immediately disconnected.

Customizable Output Control

For different raw materials, we will suggest different models of equipment to meet the crushing needs.

Discover our streamlined buying process that makes it simple and efficient for you to get a complete pellet production line. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

Henan RICHI Machinery Co., Ltd

Henan Richi Machinery Co., Ltd was founded in 1995. After nearly thirty years of development and expansion, RICHI Machinery has grown into a modern enterprise covering an area of 60,000 square meters and integrating independent research and development, production and sales.

The products involve feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveying equipment and engineering, steel structure engineering, silo, automation control technology and engineering, etc., and each product series has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

The system is fully automated, enabling seamless operation with minimal labor and supporting sustainable agricultural practices through the use of alfalfa and other forages. Of course you can also use other materials for pelletizing.

Learn More

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of pellet production line do you want to establish?

How many tons per hour about this line you want to build?

Where is this pellet production line going to be built?

When do you plan to start the operation?

A hammer mill is a machine used to grind raw materials such as grains, corn, and soybeans into fine particles for use in animal feed production. Typically in animal feed production lines the first production section is raw material handling. The grinder does not destroy the nutrition of grains, grass, straw and other raw materials, but only changes their physical properties. After grinding into powder, the multiple raw materials become more uniform when mixed into a formula, and it is easier to make a nutritionally balanced, Feed pellets with uniform texture and easy storage.

The raw material of cereals enters into the hammer mill chamber by means of a variable frequency feeding system with magnetic (removing iron impurities from the material).

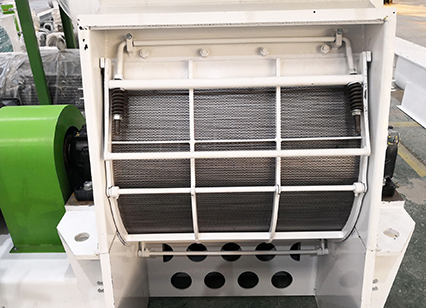

The high speed rotation of the hammer blade strikes the material. The raw material receives an impact which reduces its size, and repeated hammering further pulverizes the material to the desired size.

Coupled with the teardrop-shaped crushing cavity design, the stroke of a reasonable secondary crushing structure, greatly improving the crushing efficiency.

Reduced to a small enough material can be discharged through the screen holes. The larger ones will continue to be ground in the chamber until the desired size.

Hammer mills can handle a wide variety of materials, including grains, corn, soybeans, wheat, barley, and fibrous materials such as alfalfa and straw. In addition, RICHI Machinery's hammer mill can be used to pulverize wood chips of certain sizes. And, the same hammer mill has different outputs for different raw materials. Please contact us to find out what size of hammer mill you need for your grinding needs and we will give you the perfect solution based on your raw material and production requirements.

The output size depends on the screen mesh used, typically ranging from 1mm to 10mm, ensuring suitable particle size for different animal feed types.

Crushing particle size can be adjusted by varying screens with different apertures to achieve finer or coarser output depending on feed requirements. For animal feed production, our engineers will also help to develop and equip the right pulverizer screen when developing a plan.

Yes, modern hammer mills are equipped with energy-efficient motors and variable frequency drives to optimize power consumption while maintaining high throughput.

Regular maintenance includes inspecting and replacing worn hammers and screens, lubricating bearings, and cleaning the grinding chamber to ensure consistent performance.

Yes, it can be easily integrated with other equipment such as mixers, pellet mills, and conveyors for a fully automated production line.

Most hammer mills come with safety features such as emergency stop buttons, safety limit switches, and protective covers to prevent accidents and ensure operator safety.

It ensures uniform particle size, improves feed digestibility, and enhances overall animal nutrition while optimizing production efficiency and reducing waste.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy