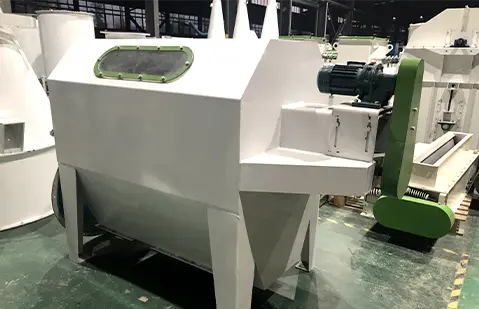

High output, low energy consumption, simple structure, small footprint, these are the advantages of cylindrical particle cleaning screen. According to the nature of the material, suitable screen can be selected. In professional animal feed mills, this has become a special equipment for cleaning impurities from various formulated raw materials together with powder cleaning screen.

Brand

RICHI

Model

SCY

| Model | Power(kw) | Production Capacity(TPH) | Screen Drum Speed(RPM) |

|---|---|---|---|

| SCY63 | 0.75 | 15-30 | 21 |

| SCY80 | 0.75 | 20-40 | 17 |

| SCY100 | 1.5 | 30-50 | 12 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of your production.

Optimized Screening Efficiency

Advanced design features, such as precision-engineered sieve apertures and variable drum speeds, have significantly improved the separation efficiency of the particle cleaning screen.

Enhanced Transmission System

The integration of energy-efficient motors and adaptive speed controls allows for optimized drum rotation and reduced energy consumption.

Durable and Wear-Resistant Materials

The use of high-strength, wear-resistant alloys and corrosion-resistant coatings on key components, such as the drum and frame, has boosted the durability of the equipment.

User-Friendly Design and Automation

Incorporating automated features, such as self-cleaning mechanisms and real-time monitoring systems, has simplified the operation and maintenance of the particle cleaning screen.

Discover our streamlined buying process that makes it simple and efficient for you to get a complete pellet production line. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

Henan RICHI Machinery Co., Ltd

Henan Richi Machinery Co., Ltd was founded in 1995. After more than 20 years of development and growth, RICHI has grown into a modern enterprises engaged in independent research and development, production and sales, Including feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveyor equipment and engineering, steel structure engineering, silos, automation control technology and engineering product development and manufacturing, design and installation. The company has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

The system is fully automated, enabling seamless operation with minimal labor and supporting sustainable agricultural practices through the use of alfalfa and other forages. Of course you can also use other materials for pelletizing.

Learn More

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of pellet production line do you want to establish?

How many tons per hour about this line you want to build?

Where is this pellet production line going to be built?

When do you plan to start the operation?

Yes, a pellet cleaning sieve can significantly help reduce dust in the production facility. By effectively separating and removing fine particles and dust from the feed pellets, the sieve minimizes the amount of airborne dust released into the environment, creating a cleaner, safer, and healthier working space. This reduction in dust not only improves air quality but also enhances the overall cleanliness and safety of the facility.

To determine the right mesh size for your pellet cleaning sieve, consider the following factors:

By carefully considering these factors and conducting tests as needed, you can select the appropriate mesh size for your pellet cleaning sieve to ensure effective separation and high-quality pellets.

The typical lifespan of a pellet cleaning sieve can range from 5 to 10 years or more, depending on factors such as the quality of materials used in construction, the frequency of operation, the type of materials processed, and the level of maintenance performed. Regular maintenance and proper handling can significantly extend the lifespan of the equipment.

Vibration frequency plays a crucial role in determining the cleaning efficiency of a pellet cleaning sieve. Specifically, higher vibration frequencies increase the energy transmitted to the pellets and fine particles, which improves the separation of small debris and dust from the pellets. This helps to ensure that fine particles pass through the mesh quickly and efficiently.

On the other hand, lower vibration frequencies may be more effective for separating larger impurities or handling heavier pellets, as they allow for more controlled movement of the materials across the screen. Adjusting the frequency based on the type and size of the material being processed can optimize the cleaning performance, ensuring that the sieve effectively separates impurities while maintaining a smooth flow of quality pellets.

Yes, it is possible to integrate the pellet cleaning sieve into an automated production line. Modern pellet cleaning sieves are designed with features that facilitate seamless integration with other equipment, such as conveyors, mixers, and packaging systems. Automation enhances the overall efficiency of the production line by enabling continuous operation, reducing the need for manual intervention, and ensuring consistent pellet quality throughout the process. Additionally, many sieves come with options for programmable controls and sensors that can communicate with the central control system for real-time monitoring and adjustments.

Pellet cleaning sieves are typically constructed from high-quality, durable materials to ensure longevity and optimal performance in feed production environments. The primary materials used include:

These materials are chosen to ensure the sieve can withstand the rigorous conditions of feed production, including exposure to dust, moisture, and abrasive particles, while maintaining performance and hygiene.

Improving the performance of your pellet cleaning sieve can be achieved through several key practices:

By following these practices, you can optimize the performance of your pellet cleaning sieve, ensuring efficient and reliable operation in your feed production line.

Common problems that may occur with a pellet cleaning sieve include:

These problems can often be mitigated with regular maintenance, proper usage, and timely adjustments to ensure the sieve continues to function efficiently in the feed production line.

To troubleshoot a clogged pellet cleaning sieve, follow these steps:

By following these steps, you can effectively address and prevent clogging issues, ensuring the pellet cleaning sieve operates efficiently.

The pellet cleaning sieve is generally designed for use with dry feed pellets. Using it with wet or sticky materials may cause clogging, reduced efficiency, or damage to the screen. If you need to process wet materials, it is recommended to dry them first or consider using specialized equipment designed to handle moisture-laden or sticky substances.

If you need further information, please contact us

Note: Pellet production is a continuous and complex process, requiring many equipment to complete the production from raw materials to finished pellets. Therefore, it is suitable for commercial projects but not for personal use.

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025