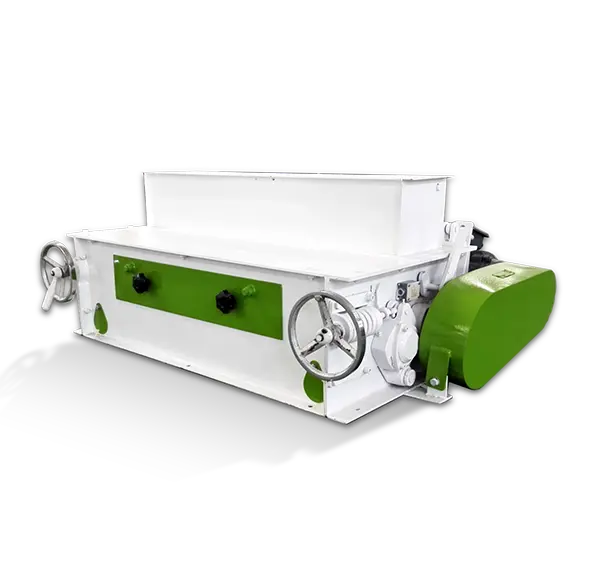

Reduce pellet size efficiently with our robust pellet crumbler. Perfect for producing uniform feed sizes for poultry and young animals.

Brand

RICHI

Model

SSLG

| Model | SSLG15*50 | SSLG15*80 | SSLG15*120 | SSLG15*150 | SSLG20*170 |

|---|---|---|---|---|---|

| Main Power(KW) | 4 | 4 | 5.5 | 7.5 | 11 |

| Crumbler Roller Dia.(cm) | 15 | 15 | 15 | 15 | 20 |

| Crumbler Roller Length(cm) | 50 | 80 | 120 | 150 | 170 |

| Number Rollers | 2 | 2 | 2 | 2 | 2 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of your production.

Precision Roller Adjustment System

Advanced mechanisms allow for micro-adjustments of the gap between the crumbling rollers, either manually or automatically via digital controls.

Enhanced Feeding Mechanism

Incorporates a controlled feeding system with even material distribution to the rollers, often with anti-blockage designs.

Energy-Efficient Drive System

Utilizes energy-saving motors and optimized power transmission systems such as high-efficiency gears or belts.

Advanced Safety and Automation

Includes overload protection, emergency stop systems, and smart sensors to monitor machine performance in real time.

Discover our streamlined buying process that makes it simple and efficient for you to get a complete pellet production line. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

Henan RICHI Machinery Co., Ltd

Henan Richi Machinery Co., Ltd was founded in 1995. After nearly thirty years of development and expansion, RICHI Machinery has grown into a modern enterprise covering an area of 60,000 square meters and integrating independent research and development, production and sales.

The products involve feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveying equipment and engineering, steel structure engineering, silo, automation control technology and engineering, etc., and each product series has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

The system is fully automated, enabling seamless operation with minimal labor and supporting sustainable agricultural practices through the use of alfalfa and other forages. Of course you can also use other materials for pelletizing.

Learn More

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of pellet production line do you want to establish?

How many tons per hour about this line you want to build?

Where is this pellet production line going to be built?

When do you plan to start the operation?

A pellet crumbler is used to reduce the size of large pellets into smaller, uniform particles. This process is essential for producing feed suitable for young animals, such as poultry chicks, piglets, or aquaculture species, which require smaller feed particles for easier consumption and digestion.

The crumbler enables precise control over the particle size by adjusting the gap between its rollers, ensuring that the crumbled feed meets specific dietary requirements. It is a vital component in feed production lines, enhancing feed versatility while maintaining nutritional integrity and pellet quality.

A pellet crumbler works by using two counter-rotating rollers to crush pellets into smaller, uniform particles. The process is precise and designed to maintain the integrity of the feed while reducing its size. Here's how it operates:

A pellet crumbler can process a wide variety of pellets, including:

Yes, a pellet crumbler can produce multiple particle sizes by adjusting the gap between the crumbling rollers. The rollers are equipped with an adjustment mechanism (manual or automatic) that allows operators to set the desired distance between them, which directly determines the size of the crumbled pellets.

The typical capacity of a pellet crumbler varies depending on the model and application. Generally, pellet crumblers are available with capacities ranging from 1 ton/hour to 20 tons/hour, making them suitable for both small-scale and industrial feed production.

No, crumbling does not affect the nutritional value. It simply reduces the pellet size for easier consumption by animals.

The pellet crumbler prevents excessive pellet breakage or the creation of fines through a combination of precise design and operational features:

Yes, modern pellet crumblers are designed with energy-saving motors and optimized drive systems to reduce power consumption.

Yes, it is designed to seamlessly integrate with conveyors, coolers, and packaging systems in fully automated production lines.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy