Different aquatic feed solutions will be paired with the right extruder or pellet mill to ensure the nutritional and stability of the aquafeed in the water and to maximize the efficiency and quality of aquafeed production.

With precise control over pellet size, texture and density, these extruders ensure optimum feed conversion and growth in aquaculture. Designed for efficiency and versatility, these extruders are ideal for the production of floating and sinking feeds.

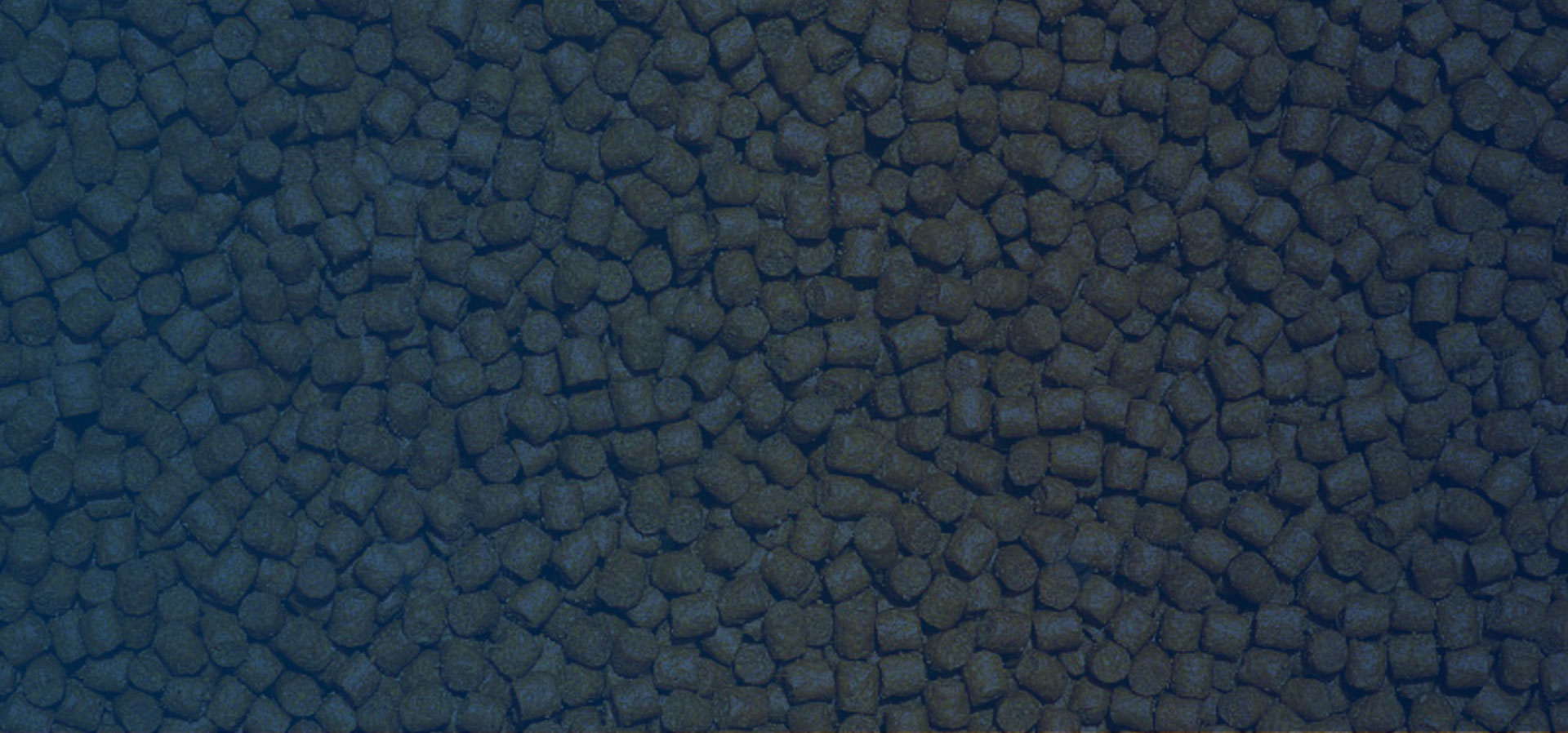

Designed to deliver consistent, durable feed pellets, our aquatic feed pellet machines are perfect for producing water-stable, nutrient-dense feed.

Designed for high output, optimized feeding, extruding and pelletizing ensure fast and consistent aquafeed production.

Highly customized aquafeed production solutions, computerized dosing system, fully automatic switching of formulas at the touch of a button.

User-friendly design, quick access to key components, simplifying cleaning, repairs and routine maintenance.

High-specification forging production, solid structure, stable operation, greatly extending service life.

What kind of pellet plant do you want to establish?

How many tons per hour about this plant you want to build?

Where is this pellet plant going to be built?

When do you plan to start the operation?

Both extrusion and pelletizing are common methods for producing aquafeed, but they differ significantly in terms of process, output characteristics, and applications. For detailed differences, please refer to the followings:

The choice between extrusion and pelletizing depends on the specific dietary needs of the aquatic species, feed type (floating, sinking, or slow-sinking), and production goals. Extrusion offers higher nutritional value and versatility but at a higher cost, while pelletizing provides a cost-effective solution for dense, sinking feed.

Extrusion is preferred for floating feed because it allows for precise control over the feed's physical properties, ensuring it remains buoyant in water for extended periods. During the extrusion process, high temperature and pressure are applied to the feed mixture, causing the starches to gelatinize and expand. This structural modification traps air within the pellets, making them less dense and enabling them to float. Additionally, extrusion enhances digestibility by breaking down complex compounds, ensures uniformity in pellet size and shape, and allows for the inclusion of various additives and nutrients without compromising feed integrity. These qualities make extruded feed highly effective and desirable for aquaculture, where controlled feeding and reduced waste are critical.

Pelletizing produces a variety of feed types tailored to the nutritional and physical needs of different animals. Livestock feed, such as for cattle, pigs, and sheep, is commonly pelletized to enhance digestibility and minimize waste. Poultry feed benefits from pelletizing as it ensures a balanced diet in a compact, easy-to-consume form for chickens, ducks, and turkeys. Aquatic feed for fish and shrimp is also pelletized, with specialized formulations and sizes to ensure stability in water and efficient nutrient absorption. Additionally, pet feed, often pelletized for uniformity and convenience, caters to dogs, cats, and other domestic animals with carefully balanced nutrients. Pelletizing ensures the production of durable, high-quality feed that meets the specific requirements of various species.

Moisture content plays a vital role in the aquafeed extrusion process, directly affecting the quality, texture and durability of the final product. We have summarized the following points after the installation and debugging of many projects:

Controlling the size of pellets in aquafeed production involves adjusting several key parameters in the pelletizing process to meet specific requirements. The primary factor is the selection of the die in the pellet mill, as the die’s hole diameter directly determines the pellet size. Dies with smaller holes produce fine pellets suitable for young or small aquatic species, while larger holes create pellets for larger fish or crustaceans.

Other factors, such as the feed formulation and particle size of the raw materials, also influence pellet size. Proper grinding and sieving ensure uniform particle sizes before pelletizing, contributing to consistent pellet dimensions. Additionally, the pressure and speed of the rollers in the pellet mill can be adjusted to regulate the density and compactness of the pellets, indirectly affecting their size.

After pelletizing, if further size customization is required, a pellet crumbler can be used to break larger pellets into smaller, uniform pieces. By carefully managing these aspects of the production process, aquafeed producers can achieve precise control over pellet size, ensuring it meets the nutritional and consumption needs of specific aquatic species.

Conditioning in extrusion is a critical pre-processing step that prepares raw materials for optimal extrusion performance. During conditioning, steam, water, or other liquids are introduced to the feed mix to adjust its temperature, moisture content, and texture. This process softens the raw materials, making them more pliable and easier to process through the extruder.

By improving the material’s consistency and homogeneity, conditioning ensures efficient energy transfer during extrusion, leading to better expansion and gelatinization. This directly impacts the quality of the final product, enhancing its durability, texture, and digestibility, particularly in applications like animal feed and aquafeed production. Proper conditioning also reduces mechanical stress on the extruder, extending its lifespan and ensuring smoother operations.

Extruders enhance nutrient retention in aquafeed by leveraging precise control over temperature, pressure, and processing time during production. This combination of factors optimizes the physical and chemical properties of the feed, ensuring better nutrient availability and stability.

If you need further information, please contact us

Note: Pellet production is a continuous and complex process, requiring many equipment to complete the production from raw materials to finished pellets. Therefore, it is suitable for commercial projects but not for personal use.

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025