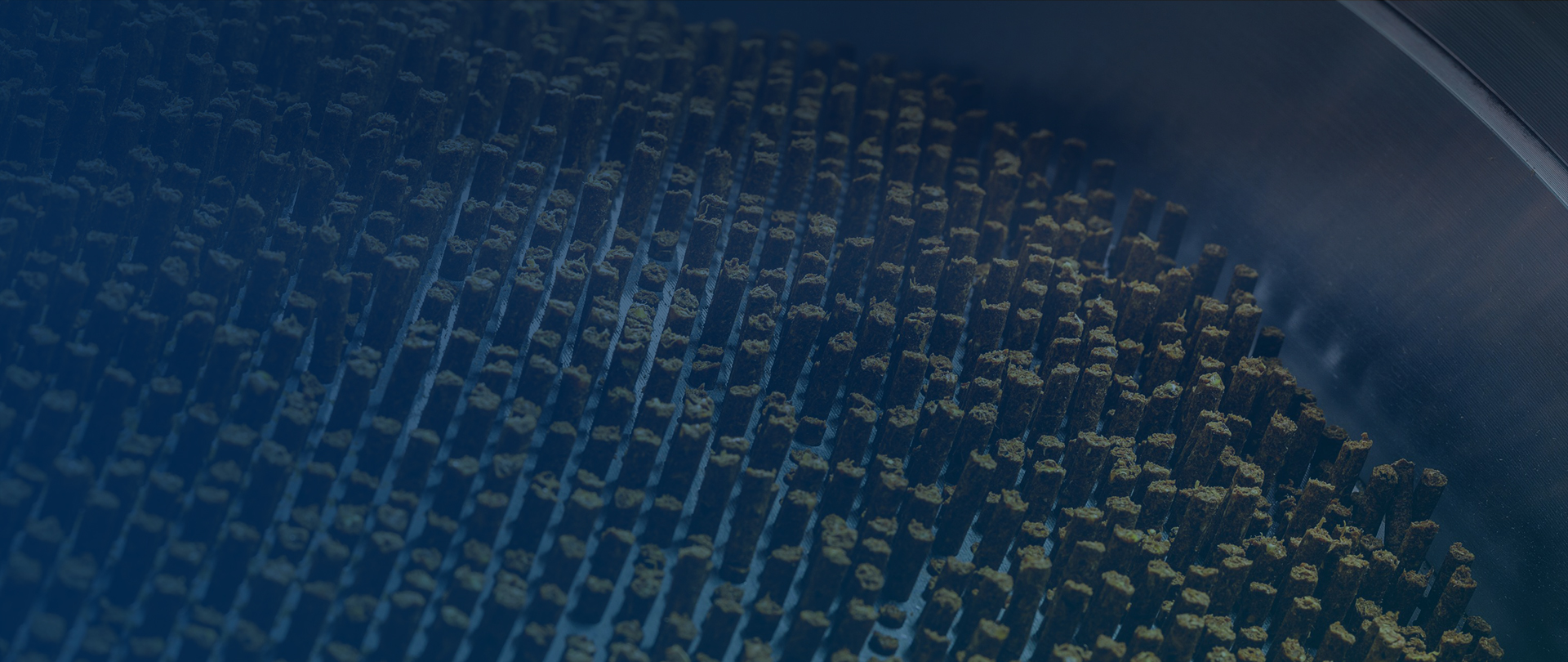

Supports 2-12mm pellet production adjustment to meet the palatability of different livestock.

Pellet production improves feed quality, nutritional value and animal feeding efficiency.

Choose from a range of pellet mills designed specifically for poultry, livestock, ruminant, or general animal feed production. Each machine is optimized for the specific nutritional requirements and production needs of different animal types.

With different models of pellet mills to choose from, you can find the perfect machine to match your production capacity and operational goals. From small-scale feed mills to large-scale industrial-scale feed plants, we have a solution for you.

Whether you’re a small scale business or a large-scale operation, our pellet mills cover production needs from low-capacity to high-capacity output, ensuring efficiency and consistent pellet quality.

Designed for high throughput, optimized feeding and pelletizing ensures fast, consistent pellet production.

Easily replace ring dies with different apertures for pellet production to meet the dietary requirements of different animal species.

User-friendly design with quick access to key components simplifies cleaning, repair and routine maintenance.

High-specification forged production, robust construction and stable operation, greatly extending service life.

What kind of pellet plant do you want to establish?

How many tons per hour about this plant you want to build?

Where is this pellet plant going to be built?

When do you plan to start the operation?

An animal feed pellet mill is a machine used to compress powdered feed materials into solid, cylindrical pellets that are easier for animals to consume and digest. These pellets are typically made for livestock, poultry, fish, and other animals, ensuring they receive balanced nutrition in a compact and convenient form.

Animal feed pellet mills are critical in modern feed production, ensuring efficient manufacturing processes and high-quality feed that meets the nutritional needs of various animals.

Feed pellet mills improve production efficiency in several key ways, making them indispensable in modern feed production processes:

By combining these benefits, feed pellet mills ensure a more efficient, cost-effective, and sustainable feed production process, meeting the needs of both small-scale and industrial-scale producers.

Yes, you can customize the pellet size in most pellet production systems. The size of the pellets is primarily determined by the die’s hole diameter used in the pellet mill. By selecting or changing the die, you can produce pellets of different sizes to meet specific requirements.

The ideal moisture content for feed pelletizing typically ranges between 10% and 15%. Maintaining this range is critical to ensure the quality, efficiency, and durability of the pellets.

Feed pellet mills require regular maintenance to ensure optimal performance, prolong equipment lifespan, and maintain consistent pellet quality. The maintenance frequency depends on factors such as production volume, material type, and operational conditions. Below is a general guideline for feed pellet mill maintenance:

By adhering to this maintenance schedule, you can minimize unexpected breakdowns, extend the life of your feed pellet mill, and ensure consistent and high-quality pellet production. Always follow the manufacturer's specific recommendations for your equipment.

Feed pellet mills are constructed from a variety of durable materials to ensure their efficiency, longevity, and ability to handle the demands of feed production. Here’s a breakdown of the primary materials used:

The lifespan of a feed pellet mill depends on several factors, including the quality of the equipment, the materials being processed, and how well it is maintained. On average, a well-maintained feed pellet mill can last between 10 to 20 years or more.

RICHI Machinery offers a diverse range of pellet production lines tailored to various capacities and material types, ensuring solutions that meet specific production requirements.

Yes, RICHI Machinery offers comprehensive technical support for both the installation and operation of their equipment. Their service system is designed to ensure that customers can utilize their pelletizing equipment effectively and without concerns.

RICHI Machinery is dedicated to providing a complete service system, aiming to free customers from any worries related to using their pelletizing equipment.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy