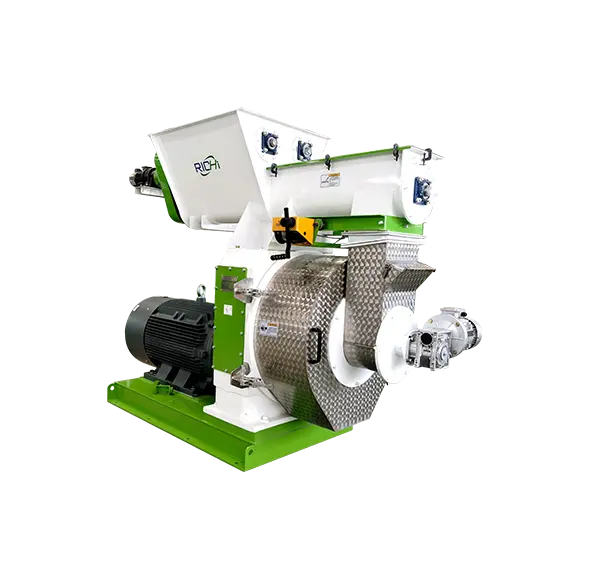

Optimized feed inlet with anti-arching configuration, supplemented by Siemens frequency conversion feeding motor, so that any straw material can be silky smooth into the pelletizing chamber, improve production efficiency and at the same time reduce the failure rate of the equipment.

Brand

RICHI

Raw Material

Straw

Finished

Pellets

| Model | CZLH320 | CZLH350 | CZLH420 | CZLH520 | CZLH678 | CZLH768 |

|---|---|---|---|---|---|---|

| Main Motor Power(Kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Arch Breaker Feeder Power(Kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(Kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter (mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished Pellets Diameter (mm) | 4~12 | 4~12 | 4~12 | 4~12 | 4~12 | 4~12 |

| Production Output (TPH) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4.0-5.0 | 6.0-8.0 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of straw pellet production.

Feeding systems

The frequency conversion feeding system with anti-arching improves the continuity and consistency of the raw material conveyed to a large extent. At the same time there is still a forced feeder escorting the feeder before pelletizing. This improves the yield and quality of the biomass pellet production from the source.

Drive system

High-end Siemens industrial grade drive motor drives the drive shaft of RICHI straw pellet mill, which is more stable and durable than traditional belt drive. In the long run, this not only improves efficiency but also saves maintenance costs.

Structure and material

The body of the machine is made of high quality and high specification alloy steel, which is sturdy and durable, reduces resonance and runs stably. The parts that come into contact with the raw material are made of high grade stainless steel, which does not affect the raw material in any way and greatly improves corrosion resistance.

Control and Safety

Each RICHI pellet machine is equipped with an independent electric control system and safety stop function. It can not only avoid losses caused by perceived errors, but also effectively protect the pellet mill and subsequent production equipment.

Explore our efficient and streamlined purchasing process, designed to simplify and optimize the acquisition of a complete straw pellet production plant. Every stage is tailored to meet your specific requirements, from the initial schematic design and precise manufacturing processes to secure payment methods and seamless on-site installation and commissioning. Furthermore, our comprehensive spare parts service provides ongoing support and ensures optimal machine performance, offering you long-term reliability and peace of mind.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

HENAN RICHI MACHINERY CO.,LTD

Henan Richi Machinery Co., Ltd was founded in 1995. After nearly thirty years of development and expansion, RICHI Machinery has grown into a modern enterprise covering an area of 60,000 square meters and integrating independent research and development, production and sales.

The products involve feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveying equipment and engineering, steel structure engineering, silo, automation control technology and engineering, etc., and each product series has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

The system is fully automated, enabling seamless operation with minimal labor and supporting sustainable agricultural practices through the use of alfalfa and other forages.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What raw materials do you intend to use for pellet production?

How many tons per hour about this plant you want to build?

Where will your pellet mill plant be built?

When do you plan to start this project?

The ideal moisture content for straw pellets is typically 10-15%. This level ensures the straw is neither too dry nor too moist, which helps the pelletizing process run smoothly and produces durable, high-quality pellets. Moisture levels outside this range can cause issues like pellet crumbling if too dry, or clogging and inefficient pellet formation if too moist.

Yes, straw pellets can be used as fuel. They are a form of biomass energy and provide an eco-friendly alternative to fossil fuels. Due to their high energy content, straw pellets are suitable for heating applications in boilers and stoves, especially in areas where straw is readily available. They burn cleanly with low ash content and can contribute to reducing carbon emissions when used as a renewable energy source.

Yes, straw pellet machines are designed to be energy-efficient, optimizing the process to produce high-quality pellets with minimal power usage. By incorporating advanced technology, they reduce energy consumption while maintaining consistent pellet quality, which is beneficial for both large-scale and small-scale production. Efficient power use not only lowers operational costs but also contributes to sustainable production practices.

Yes, straw pellets can be used as animal bedding. They are highly absorbent, helping to keep animal enclosures dry and clean. Additionally, straw pellets produce minimal dust, making them a healthier bedding option for animals. They also break down easily, making them more convenient to clean and dispose of than traditional straw bedding. This versatility makes straw pellets a popular choice for livestock and pet bedding alike.

The production capacity of straw pellet machines varies depending on the model and design but generally ranges from 500 kg to 10 tons per hour. Smaller models are ideal for limited output needs, while industrial-scale machines are suited for large-volume pellet production. The exact capacity will depend on factors like raw material consistency, moisture content, and machine specifications.

Yes, straw pellets require a cooling process after pelletizing. During production, the pellets come out hot and soft due to the heat generated by compression and friction. Cooling helps to harden the pellets, maintain their structure, and reduce moisture content to optimal levels, which improves durability and prevents mold growth. This process ensures the pellets remain stable during storage and transport, preserving quality for longer periods.

Straw pellet machines typically offer various pellet sizes, ranging from 6 mm to 10 mm in diameter, with some models supporting up to 12 mm or more. The optimal pellet size depends on the intended use, such as biofuel or animal bedding, and can be customized by changing the die in the machine. Smaller pellets are usually preferred for combustion efficiency, while larger sizes may be suitable for animal bedding due to higher absorbency.

Yes, operator training is typically recommended for using a straw pellet machine. Training ensures operators understand the machine's setup, optimal operation, and routine maintenance practices. This knowledge helps maximize efficiency, maintain consistent pellet quality, and reduce wear and tear. Training also covers safety protocols, which are essential when operating large industrial machinery, especially during prolonged use in agricultural and biomass production settings. Skilled operators can troubleshoot issues more effectively, minimizing downtime and extending the equipment's lifespan.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy