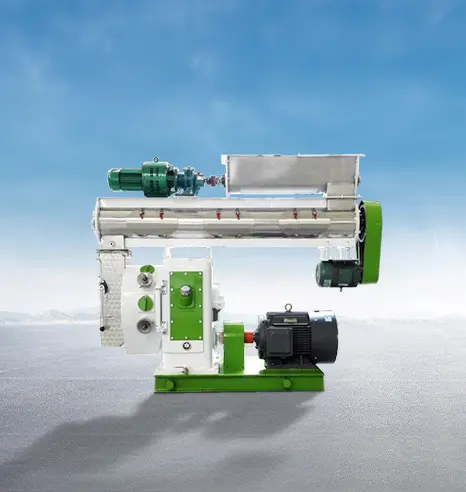

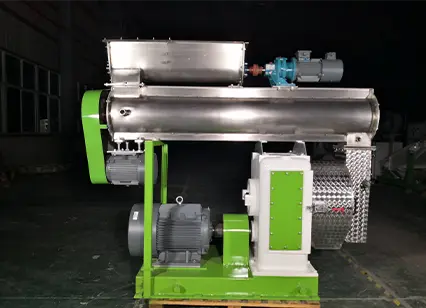

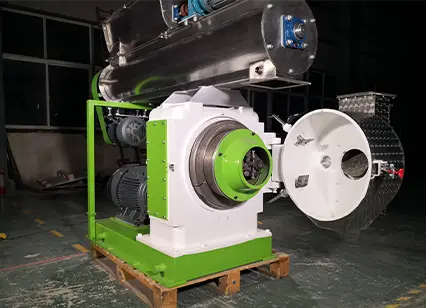

With optimized feed inlets, well-designed conditioners, efficient pelletizing chambers, and stable Siemens motors, RICHI Machinery’s high-specification body structure is engineered to be the core of any feed pellet production process. These features ensure maximum efficiency, stability, and durability, making it an essential component for producing high-quality feed pellets in large-scale operations.

Brand

RICHI

Application

Poultry

Finished

Pellets

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

|---|---|---|---|---|---|---|---|---|

| Main Motor Power(Kw) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder Power(kw) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Conditioner Power(kw) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Ring Die Inner Diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 |

| Finished Pellets Diameter (mm) | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 |

| Production Output (TPH) | 1.0-1.5 | 3-4 | 5-6 | 10-12 | 15-16 | 20-22 | 30-33 | 38-40 |

The aim of technological innovation is to serve the customer. Let the convenience of RICHI's products and technology and the solutions we offer in the production of animal feed pellets give you perfect results.

Feeding and conditioning systems

The optimized conditioning system with inverter feeding system improves the safety, nutritional value and maturation of the raw material to a great extent. This improves the overall quality of the feed from the source and ensures healthy feeding.

Drive system

High-end Siemens industrial grade drive motor drives the drive shaft of RICHI poultry feed pellet mill, which is more stable and durable than traditional belt drive. In the long run, this not only improves efficiency but also saves maintenance costs.

Structure and material

The body of the machine is made of high quality and high specification alloy steel, which is sturdy and durable, reduces resonance and runs stably. The parts that come into contact with the raw material are made of high grade stainless steel, which does not affect the raw material in any way and greatly improves corrosion resistance.

Control and Safety

Each feed pellet mill is equipped with an independent electric control system and safety stop function. It can not only avoid losses caused by perceived errors, but also effectively protect the pellet mill and subsequent production equipment.

Discover our streamlined buying process that makes it simple and efficient for you to get a complete poultry feed pellet production plant. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

HENAN RICHI MACHINERY CO.,LTD

Henan Richi Machinery Co., Ltd was founded in 1995. After more than 20 years of development and growth, RICHI has grown into a modern enterprises engaged in independent research and development, production and sales, Including feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveyor equipment and engineering, steel structure engineering, silos, automation control technology and engineering product development and manufacturing, design and installation. The company has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

The system is fully automated, enabling seamless operation with minimal labor and supporting sustainable agricultural practices through the use of alfalfa and other forages.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of animal feed plant do you want to establish?

How many tons per hour about this plant you want to build?

Where is this animal feed plant going to be built?

When do you plan to start the operation?

The purpose of the powder cleaning sieve in animal feed production is to remove impurities such as stones, metal particles, and large debris from raw materials, ensuring that only clean and safe ingredients are used in the feed. This process enhances the quality of the final product and protects downstream equipment from potential damage.

These raw materials can be combined to meet the specific nutritional needs of poultry at different growth stages.

The ideal pellet size for poultry varies based on the age and type of bird. For chicks, the recommended pellet size is 2-4 mm to make it easy for them to consume and digest. For adult poultry, such as chickens and ducks, the pellet size typically ranges from 4-6 mm. This size ensures that the birds can efficiently eat and process the feed, promoting better growth and overall health. Proper pellet size also reduces waste and enhances feed conversion efficiency.

The power consumption of feed pellet mills varies depending on their size, model and capacity. Individual pellet makers range from 20-300kW, and complete feed pellet production lines contain more equipment, so depending on the size of the solution and the level of production, the total power ranges from tens kilowatts to hundreds kilowatts, with high capacity production lines capable of reaching thousands kilowatts. Energy-efficient models are designed to reduce power consumption while maintaining high output. To determine the exact power consumption, it is important to check the specifications of the machine you are using or planning to purchase.

Yes, operator training is necessary for running poultry feed pellet making machines effectively. Proper training ensures operators understand how to set up, operate, and maintain the equipment, resulting in efficient production and consistent pellet quality. Training also covers safety measures to prevent accidents and teaches best practices for troubleshooting and maintaining the machine. Skilled operators can maximize the machine’s lifespan and minimize operational disruptions, which is crucial for maintaining productivity in poultry feed production facilities.

The time it takes to produce pellets with a chicken feed pellet machine depends on factors such as machine capacity, raw material preparation, and pellet size. Generally, a well-maintained machine can produce feed pellets within 30 minutes to a few hours, depending on the size of the batch and the efficiency of the equipment. Larger machines with higher capacities can produce pellets faster than smaller, manual machines.

Yes, chicken feed making machines can handle multiple types of feed formulations. These machines are designed to process various ingredients such as corn, soybean meal, wheat, and other grains, as well as different additives based on the nutritional requirements for poultry at different growth stages. By adjusting the machine's settings and formulations, you can produce feed for different types of birds, such as broilers, layers, and breeders, ensuring that each type of poultry receives the appropriate nutrition for optimal growth and health.

Maintenance on a chicken feed pellet making machine should generally be performed regularly to ensure optimal performance. Daily maintenance includes checking for any blockages, cleaning the feed inlet, and inspecting moving parts for wear. Weekly or bi-weekly maintenance may involve lubricating key components, tightening any loose bolts, and checking the condition of the die and rollers. Additionally, a more thorough monthly or quarterly maintenance should be conducted, including inspecting electrical systems and replacing worn parts. Regular maintenance helps extend the lifespan and efficiency of the machine.

Yes, a pellet machine can be customized based on specific production requirements. Customization options often include adjusting the pellet size, machine capacity, feed inlet design, and even adding features like automation for better control and efficiency. Depending on the type of raw material and the desired pellet output, the machine can be tailored to produce feed for various animals, including poultry, livestock, or aquatic species. This flexibility allows manufacturers to optimize production for different scales and applications.

The expected lifespan of a chicken feed making machine is typically between 10 to 15 years with proper maintenance. Regular maintenance, such as lubrication, cleaning, and timely replacement of wear parts like dies and rollers, helps extend the machine's life and ensure consistent performance. The durability of the machine also depends on the quality of materials used in its construction and the working conditions it operates under. Proper usage and care can maximize its operational lifespan.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy