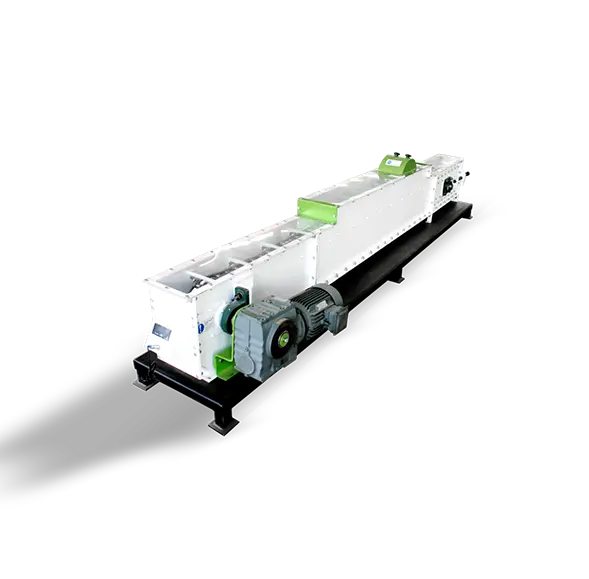

Ensure smooth and efficient material transfer with our heavy-duty scraper conveyor, built for high-capacity pellet production lines.

Brand

RICHI

Model

TGSS

| Model | TGSS16 | TGSS20 | TGSS25 | TGSS32 | TGSS40 |

|---|---|---|---|---|---|

| Output(m³/h) | 20~30 | 50~60 | 80~90 | 120~140 | 180~210 |

| Distance of scraper chain link(mm) | 66.75 | 66.75 | 66.75 | 66.75 | 66.75 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of your production.

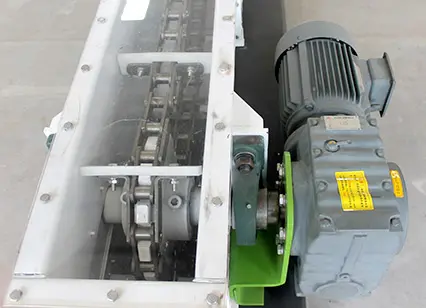

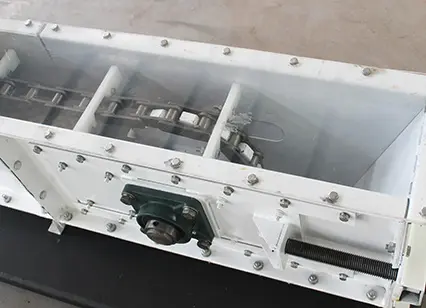

Optimized Scraper Chain Design

The scraper chain is designed with wear-resistant materials and precision-engineered links to ensure durability and efficiency in material handling.

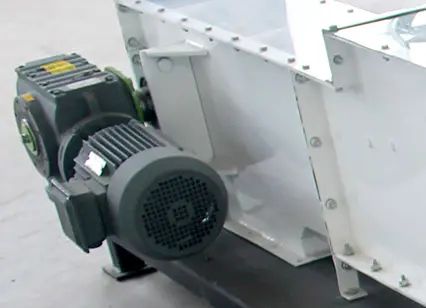

Energy-Efficient Drive System

Incorporates high-efficiency motors and advanced gearboxes, with variable speed control options.

Advanced Sealing and Dust Control

Features enhanced sealing systems to minimize dust leakage and maintain cleanliness in the production environment.

Modular and Customizable Construction

Modular design allows for flexible configurations and easy integration with other production line equipment.

Discover our streamlined buying process that makes it simple and efficient for you to get a complete pellet production line. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

Henan RICHI Machinery Co., Ltd

Henan Richi Machinery Co., Ltd was founded in 1995. After more than 20 years of development and growth, RICHI has grown into a modern enterprises engaged in independent research and development, production and sales, Including feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveyor equipment and engineering, steel structure engineering, silos, automation control technology and engineering product development and manufacturing, design and installation. The company has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

The system is fully automated, enabling seamless operation with minimal labor and supporting sustainable agricultural practices through the use of alfalfa and other forages. Of course you can also use other materials for pelletizing.

Learn More

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of pellet production line do you want to establish?

How many tons per hour about this line you want to build?

Where is this pellet production line going to be built?

When do you plan to start the operation?

A scraper conveyor is used to transport bulk materials, such as raw materials, semi-processed products, or finished pellets, within a pellet production line. Its design allows for efficient and continuous horizontal or inclined material movement while preventing spillage. The conveyor plays a critical role in streamlining production workflows, reducing manual handling, and ensuring that materials are delivered to subsequent stages of the production process smoothly and efficiently.

The scraper conveyor operates by moving a chain with attached scrapers through a conveyor trough. The scrapers push or pull the material along the trough, depending on the conveyor’s configuration. The movement is powered by a drive system consisting of a motor and gearbox, ensuring consistent and controlled material flow. This design allows the conveyor to handle a variety of bulk materials, even those that are granular, powdery, or sticky, making it highly versatile in production environments.

Scraper conveyors are designed to handle a wide range of materials, including:

This versatility makes the scraper conveyor suitable for various industries, such as feed, biomass, and food processing.

Yes, scraper conveyors can handle both horizontal and inclined transport. For inclined setups, the scrapers are designed to maintain material stability and prevent sliding. The angle of inclination depends on the specific design and material type, but most systems can handle inclinations up to 30 degrees effectively.

The capacity of a scraper conveyor depends on its size, chain speed, and material type. Capacities can range from 1 ton/hour to over 50 tons/hour, making it suitable for both small-scale and large industrial production lines. Manufacturers can customize the conveyor to match specific production needs.

Scraper conveyors are designed for energy efficiency, utilizing optimized drive systems and low-friction components to reduce power consumption. Additionally, their ability to handle high volumes of material in a compact space further improves energy efficiency by minimizing operational steps and equipment use.

Yes, scraper conveyors are highly compatible with automated systems. They can be integrated with other equipment such as pellet mills, dust collectors, and bagging systems. Advanced control systems allow for synchronized operation, ensuring smooth material flow and consistent production efficiency in fully automated lines.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy