Achieve superior feed quality with our SFSP fine grain hammer mill. Designed for efficient grinding of grains and raw materials, it delivers fine, uniform particles to enhance feed digestibility and improve animal nutrition. Perfect for high-capacity feed production lines.

Brand

RICHI

Model

SFSP

| Model | SFSP56*40 | SFSP66*60 | SFSP66*60 | SFSP66*80 | SFSP66*80 | SFSP66*80 | SFSP66*100 | SFSP66*100 | SFSP66*100 | SFSP66*120 | SFSP66*120 | SFSP66*120 | SFSP66*150 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rotor Dia.(mm) | 560 | 660 | 660 | 660 | 660 | 660 | 660 | 660 | 660 | 660 | 660 | 660 | 660 |

| Crushing Chamber Width(mm) | 400 | 600 | 600 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1200 | 1200 | 1200 | 1500 |

| Rotating Speed(mm) | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 |

| Line Speed of Hammers(m/s) | 88 | 103 | 103 | 103 | 103 | 103 | 103 | 103 | 103 | 103 | 103 | 103 | 103 |

| Power(kw) | 37 | 55 | 75 | 75 | 90 | 110 | 110 | 132 | 160 | 160 | 185 | 220 | 220 |

| Production Output(For Grain)(TPH) | 3-5 | 5-6 | 6-7 | / | 8-10 | 10-12 | / | 15-17 | 20-22 | / | 25-27 | 30-32 | 40-50 |

| Production Output(For Grass/Straw)(TPH) | 0.8-1.0 | 1.0-1.5 | / | 2.0-2.5 | / | / | 3.0-4.0 | / | / | / | 5.0-6.0 | / | 7.0-8.0 |

| Production Output(For Wood Chips)(TPH) | 0.5-0.6 | 1.0-1.2 | / | / | 2.0-2.5 | / | / | 3.0-4.0 | / | / | 4.0-5.0 | 5.0-6.0 | 7.0-8.0 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of your production.

Intelligent Control System

Features real-time monitoring and automated adjustments for feed rate and grinding speed.

Energy Optimization

Equipped with the latest models of high-specification Siemens motors, every machine is stable and continuously running.

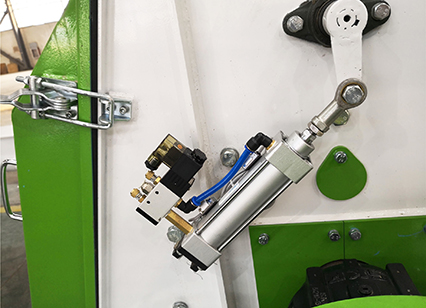

Security Apparatus

Travel switches maximize the safety of the equipment and the operator. In the event of a problem, power is immediately disconnected.

Customizable Output Control

For different raw materials, we will suggest different models of equipment to meet the crushing needs.

Discover our streamlined buying process that makes it simple and efficient for you to get a complete pellet production line. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

Henan RICHI Machinery Co., Ltd

Henan Richi Machinery Co., Ltd was founded in 1995. After nearly thirty years of development and expansion, RICHI Machinery has grown into a modern enterprise covering an area of 60,000 square meters and integrating independent research and development, production and sales.

The products involve feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveying equipment and engineering, steel structure engineering, silo, automation control technology and engineering, etc., and each product series has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

The system is fully automated, enabling seamless operation with minimal labor and supporting sustainable agricultural practices through the use of alfalfa and other forages. Of course you can also use other materials for pelletizing.

Learn More

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of pellet production line do you want to establish?

How many tons per hour about this line you want to build?

Where is this pellet production line going to be built?

When do you plan to start the operation?

The SFSP hammer mill stands out from standard hammer mills due to its specialized design for fine grinding and higher efficiency. Here are the key differences:

These features make the SFSP hammer mill a superior choice for industries requiring precise and efficient grinding, such as animal feed and aquaculture.

Yes, the SFSP hammer mill can handle materials with moderate moisture content, but its efficiency may decrease as the moisture level increases. For optimal performance, it is recommended to use materials with a moisture content between 10-15%. Higher moisture levels can lead to issues such as clogging, reduced grinding efficiency, and increased energy consumption. To process high-moisture materials effectively, pre-drying systems or specialized hammer mills designed for wet grinding may be required.

The hammer mill plays a crucial role in enhancing feed quality by ensuring the feed particles are ground to a uniform size, which improves digestibility and nutrient absorption for animals. Here’s how:

By optimizing the grinding process, the hammer mill directly contributes to the production of high-quality, nutritionally balanced feed that meets the dietary needs of livestock, poultry, or aquaculture.

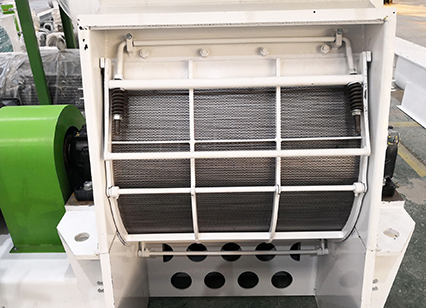

Yes, changing the screen mesh in the SFSP hammer mill is designed to be quick and straightforward. The machine typically features an accessible grinding chamber and a simple locking mechanism for the screens. This allows operators to easily remove and replace the screen with minimal downtime. The ability to quickly switch screens enhances productivity by enabling fast adjustments to achieve the desired particle size for different feed formulations.

No, it comes equipped with a dust collection system or can be connected to an external dust collector to minimize dust emissions and maintain a clean working environment.

The SFSP hammer mill is designed to minimize dust production during operation. It features an enclosed grinding chamber and can be equipped with integrated dust collection systems or connected to external dust collectors. These measures effectively reduce dust emissions, ensuring a cleaner and safer working environment. Regular maintenance, such as inspecting seals and cleaning filters, further helps in controlling dust levels.

The hammer mill typically requires a three-phase power supply, which provides the necessary voltage and current for its high-capacity motor. The specific power requirements depend on the machine’s model and capacity, with power ratings generally ranging from 10 kW to 200 kW or more. It's important to ensure that your facility’s electrical system meets these requirements to guarantee optimal performance and safe operation.

The hammers and screens in the SFSP Fine Grain Hammer Mill are designed for high durability. They are typically made from wear-resistant, hardened steel or other robust materials, ensuring long service life even under continuous, heavy-duty operation. With proper maintenance, such as regular inspections and timely replacements, these components can withstand the demands of grinding tough materials, maintaining optimal performance and minimizing downtime

Yes, the SFSP Fine Grain Hammer Mill is designed to handle both coarse and fine grinding.

Interchangeable Screens: The machine comes with various screen meshes that can be easily swapped to achieve different particle sizes. Finer screens produce smaller particles, while coarser screens allow for larger particle output.

Adjustable Operating Parameters: The hammer mill’s speed and feed rate can be adjusted to suit different grinding requirements, optimizing performance for both coarse and fine grinding applications.

This adaptability makes it ideal for a wide range of feed production needs, allowing users to process different raw materials efficiently and meet specific feed quality standards.

Yes, technical support is available for the installation and operation of the SFSP Fine Grain Hammer Mill. Manufacturers typically offer comprehensive services, including:

For instance, we provides detailed instructions and support for our SFSP Fine Grain Hammer Mill, ensuring customers can effectively utilize the equipment in their feed production processes.

It's advisable to contact the manufacturer or authorized dealer directly to discuss your specific needs and arrange for the necessary support services.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy