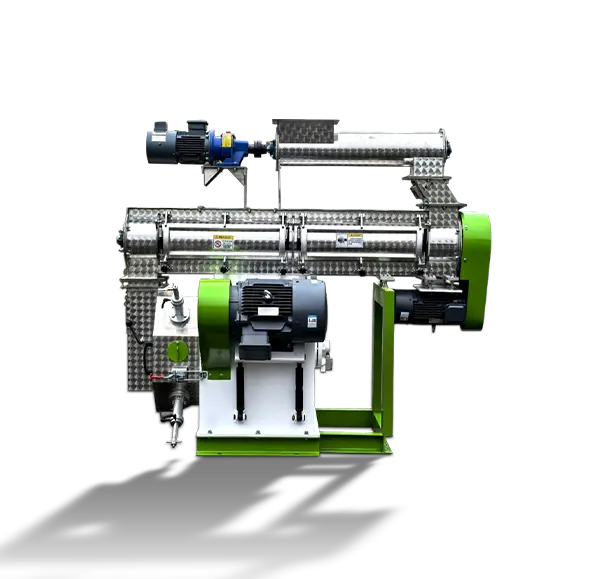

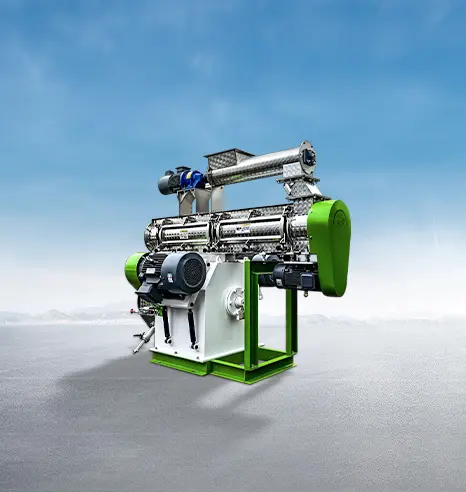

Optimized feed inlet with stainless steel conditioner, stable double belt type Siemens motor, ring die and pressure roller made of high specification alloy steel, all these advantages are enough to make it the core equipment for small scale feed pellet production.

Brand

RICHI

Model

SZLH 250

Application

Animal

Finished

Pellets

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

|---|---|---|---|---|---|---|---|---|

| Main Motor Power(Kw) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder Power(kw) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Conditioner Power(kw) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Ring Die Inner Diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 |

| Finished Pellets Diameter (mm) | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 |

| Production Output (TPH) | 1.0-1.5 | 3-4 | 5-6 | 10-12 | 15-16 | 20-22 | 30-33 | 38-40 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of animal feed production.

Feeding and conditioning systems

The optimized conditioning system with inverter feeding system improves the safety, nutritional value and maturation of the raw material to a great extent. This improves the overall quality of the feed from the source and ensures healthy feeding.

Drive system

The dual belt drive system helps distribute power evenly from the motor to the feed pellet mill. It reduces sudden torque shocks, ensuring smoother operation and less wear and tear on machine components. It extends the life of the motor and pelletizing components.

Structure and material

The body of the machine is made of high quality and high specification alloy steel, which is sturdy and durable, reduces resonance and runs stably. The parts that come into contact with the raw material are made of high grade stainless steel, which does not affect the raw material in any way and greatly improves corrosion resistance.

Control and Safety

Each RICHI feed pellet mill is equipped with an independent electric control system and safety stop function. It can not only avoid losses caused by perceived errors, but also effectively protect the pellet mill and subsequent production equipment.

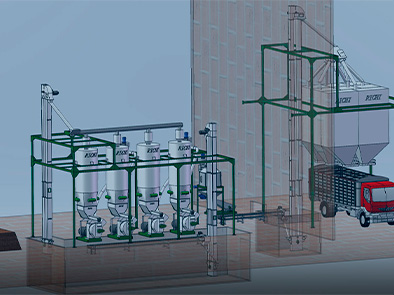

Discover our streamlined buying process that makes it simple and efficient for you to get a complete animal feed pellet mill plant. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

HENAN RICHI MACHINERY CO.,LTD

Henan Richi Machinery Co., Ltd was founded in 1995. After nearly thirty years of development and expansion, RICHI Machinery has grown into a modern enterprise covering an area of 60,000 square meters and integrating independent research and development, production and sales.

The products involve feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveying equipment and engineering, steel structure engineering, silo, automation control technology and engineering, etc., and each product series has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

The system is fully automated and requires minimal labor. Customized pellet production solutions can be switched at the touch of a button in the control room for pelletizing a wide range of raw materials.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of animal feed plant do you want to establish?

How many tons per hour about this plant you want to build?

Where is this animal feed plant going to be built?

When do you plan to start the operation?

The SZLH250 feed pellet mill is designed to be an economical choice for small to mid-size feed producers. While exact pricing can vary by supplier and added options, the feed pellet mill machine price for the SZLH250 is generally considered budget-friendly for startups. In our experience (over 30 years in the field), customers appreciate that this model offers solid output and durability without breaking the bank. Many first-time feed mill owners are relieved to find an SZLH250 feed pellet mill for sale at a reasonable cost, and they often recoup their investment quickly by producing their own feed. It’s not just about the upfront price – the long-term value comes from its efficiency and the savings you get by not having to buy external feed. Overall, if you’re starting a feed business on a tight budget, the SZLH250 is absolutely worth considering as a cost-effective, small feed pellet mill solution.

Yes, the SZLH250 is relatively compact and well-suited for places where space is tight. We often call it a small feed pellet mill because it’s designed with a smaller footprint compared to large industrial machines. Think of a unit that can snugly fit in a modest shed or a small barn corner – it’s roughly the size of a household refrigerator (with a bit more length due to the feeder and conditioner). In our global installations – from Southeast Asian villages to African countryside farms – we’ve squeezed SZLH250 pellet mills into some pretty tight spots! All you need is a solid, level floor and about a few meters of clearance for operation and maintenance. Despite its small size, it’s built sturdy, so you get a powerful poultry feed pellet mill without needing a huge dedicated space. This makes it ideal for new entrepreneurs or farmers who want to start feed processing but only have a limited area available.

The SZLH250 feed pellet mill can produce roughly 1 to 2 tons of feed pellets per hour. To put that into perspective, 1 ton of feed could roughly feed around 500–1000 chickens per day (depending on how much each chicken eats) or a good number of pigs or goats. In our experience, this output is plenty for a small to medium poultry feed operation or a livestock farm. Many of our customers running mid-sized chicken farms find the SZLH250 more than meets their daily feed production needs. And if you have a larger operation, you can run the mill longer hours or use multiple units to scale up. The key point is that the SZLH250 offers reliable throughput – you’ll get a steady stream of pellets hour after hour. So whether you’re making feed for your own chickens or selling to local farmers, this chicken feed pellet mill’s output is usually sufficient and can even create a surplus. Plus, the pellet quality is consistent, which means your animals get uniform nutrition every batch.

Don’t worry – the SZLH250 is beginner-friendly and designed with ease of use in mind. We’ve installed these machines for small farmers from Africa to South America, many of whom had never used a pellet mill before, and they usually get the hang of it quickly. The machine’s controls are straightforward: you typically have a feeder speed control, a main motor switch, and safety indicators. Our team (with 30+ years of experience) always provides initial training during installation, walking you through how to start the mill, adjust settings, and what to watch out for. After a day or two of practice, most operators feel comfortable running this poultry feed pellet mill on their own. Think of it like learning to use a new farm tractor or a maize grinder – it might seem technical at first, but with guidance and a bit of hands-on experience, it becomes routine. Plus, the SZLH250 has safety features (like overload protection) and a clear manual, so even if you’re completely new, you’re not alone – you’ve got our support and a user-friendly design on your side.

Purchasing an SZLH250 from us means you’re not just getting a machine – you’re getting our full support based on decades of experience. We pride ourselves on being there for our customers worldwide. Here’s what you can expect in terms of support:

In short, we stand behind the SZLH250 with strong after-sales service. Many of our customers stay with us for years, upgrading their equipment as they grow, precisely because they trust our support. You’ll get peace of mind knowing that help is available whenever you need it, keeping your feed pellet mill running smoothly.

From a business perspective, the SZLH250 can be a very smart investment. Many of our clients tell us that once they start producing their own feed, they see big savings. Instead of buying expensive commercial feed, they use local ingredients (corn, soy, etc.) and turn them into pellets, cutting feed costs significantly. If you’re running a farm, those savings mean the machine begins paying for itself. Some customers even produce a bit extra and sell the additional pellets to neighboring farms – suddenly your small feed pellet mill is generating revenue, not just feed.

As for ROI, it varies, but we’ve seen cases where farmers recover the cost in as quick as 1-2 years. For instance, a poultry farmer in Africa who used to spend a lot on chicken feed now uses the SZLH250 to make feed and saved enough that within a year the machine’s cost was covered. Plus, the quality of feed you get with your own poultry feed pellet mill can improve animal health and growth, which can boost your farm’s productivity (healthier chickens, faster weight gain, etc.). And remember, our company has 30+ years of experience, so we’ve optimized this model for longevity – it’s not a short-term gadget, it’s a long-term asset. Over, say, 5-10 years of use, the return multiplies because the machine keeps churning out feed with only routine maintenance costs. In summary, for most new feed businesses or farms, the SZLH250 is absolutely a worthwhile investment that can yield solid returns relatively quickly, especially when you take advantage of local materials and possibly feed sales.

The SZLH250 is quite versatile when it comes to feed types. It’s not limited to just one kind of animal feed – in fact, you can formulate pellets for poultry, livestock, and even some aquaculture with this machine. Many people start out using it as a chicken feed pellet mill, producing pellets for broilers or layers, which it does excellently. But you can certainly make feed for other animals too. For example, by adjusting your ingredient mix and maybe using a different die size, you can produce cattle feed pellets or pig feed pellets. We have customers who make feed for ducks, rabbits, goats, and sheep using the SZLH250 – it handles all those formulas well.

For fish feed, since fish (especially species like tilapia or catfish) often need sinking pellets, the SZLH250 can produce sinking fish feed pellets if you include binders and the right ingredients (floating fish feed usually requires an extruder, but sinking feed is doable on a pellet mill). In Asia, some clients use it to make duck and fish feed; in Africa, others make goat and chicken feed on the same machine. It’s basically a poultry feed pellet mill that moonlights as a multi-purpose feed machine. Our decades of experience have gone into ensuring the machine’s design is flexible. The key is to use the right feed formulation for each animal – and we can guide you on that. In short, whether you’re feeding chickens, pigs, cows, or fish, the SZLH250 can likely produce the pellets you need, making it a one-stop solution for a mixed farm or a feed supply business catering to various animals.

Maintaining the SZLH250 is straightforward – if you treat it like your farm tractor or any essential equipment, with regular check-ups, it will serve you for years. Here are some simple maintenance tips we recommend (based on our 30-year support history):

The good news is, spare parts for the SZLH250 are readily available. Since we have a global customer base, we keep a stock of common parts and can ship them to you quickly – whether you’re in South America or Southeast Asia. We’ve standardized a lot of components, so even locally you might find compatible parts. With the support network we’ve built over 30 years, maintaining an SZLH250 is not a heavy burden. Many owners tell us the machine is “low-maintenance,” needing just regular TLC. In summary: keep it clean, keep it lubed, check parts occasionally, and it will reward you with reliable service. And remember, you’re part of our family when you buy one – our after-sales team will help remind you of maintenance schedules and troubleshoot issues should they arise.

You can purchase the SZLH250 feed pellet mill directly from us (the manufacturer) or through our authorized distributors, and yes – we absolutely ship internationally. In fact, a large part of our 30+ years in business has been working with customers all over the globe. We’ve sent feed pellet mills for sale to Nigeria, Ghana, Kenya, Indonesia, the Philippines, Brazil, Ukraine – you name it. Shipping logistics are something we’re very familiar with. We prepare the machine for export (robust crating and wrapping to protect it on its journey), handle the necessary paperwork, and arrange transport to your nearest port. If you’re inland, we can coordinate with local freight companies to get it delivered to your door.

Once it arrives, we don’t leave you hanging. As mentioned earlier, we can send an engineer to help with installation, or sometimes we partner with local technicians who are trained on our equipment. Even if you’re in a remote area, we strive to make the process smooth – we’ve installed pellet mills on highlands in Peru and in tropical areas of Southeast Asia. The key is communication: we’ll work with you on power requirements (ensuring you have the right electrical setup), space prep, and scheduling the installation/training visit. Purchasing is simple too: you can contact us via our website or phone to get a quote, and we’ll guide you through payment and shipping arrangements. By buying from us, you’re tapping into a worldwide network of successful installations, so you can feel confident that distance isn’t a barrier. In short, feed pellet mill for sale isn’t just a phrase – we actively make sure that wherever you are, the SZLH250 can be delivered and set up for you to start making feed without hassle.

Installing the SZLH250 is a coordinated process, but we make it as painless as possible. If you’re technically inclined, you might handle some of it yourself, but we generally recommend letting our team help so everything is done correctly and efficiently. When the machine arrives, typically you’ll need: a solid floor or base to place it (a concrete floor is ideal to hold the weight and keep it stable), the right electrical connections (the SZLH250 usually runs on three-phase power, common in industrial settings or farms with generators), and any necessary peripherals like a feed mixer or a simple conveyor if you’re automating feed flow.

Our standard practice, honed over 30 years of global service, is to either send our engineer or coordinate with a local expert to assist you. The installation involves assembling the main parts (if it’s a single unit, it might already be mostly assembled – often just the feeder or conditioner needs attachment), aligning the pellet mill, and securing it in place. We then go through a test run: checking that the die and rollers are correctly installed, running the motors, and calibrating the feeder speed. During this process, we actually involve you or your staff – it’s a hands-on training opportunity. Within a day or two, the SZLH250 feed pellet mill should be fully set up and producing test pellets. We’ll show you how to adjust pellet size, how to change dies, and what sounds/flows are “normal” so you know everything is working right.

Many of our customers in places like Africa or Southeast Asia start off nervous about installation, but afterwards they’re amazed at how smoothly it went with our guidance. If you ever need to relocate the machine, the process is similarly straightforward: disconnect, move, and reconnect – we can advise on that too. Ultimately, while you can set it up yourself with the detailed manuals we provide, you’re never alone. We’re here to ensure your SZLH250 is installed correctly and you’re comfortable operating it. It’s all part of the comprehensive service we offer, leveraging our extensive experience to get you from delivery to production in the shortest time possible.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy