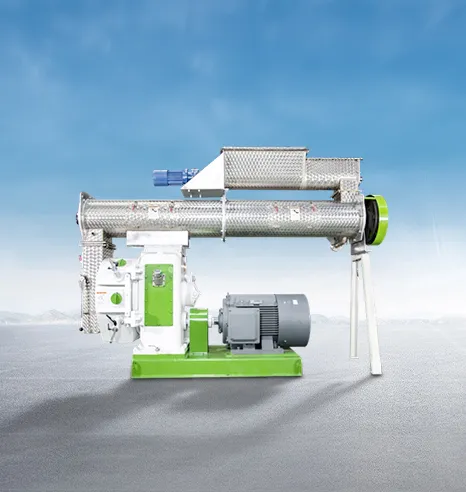

Frequency conversion feeding system, steam tempering system, double pressure roller pelletizing system, Siemens electronic control system, plus alloy steel forging body, these become the core of animal feed mill pellet machine.

Brand

RICHI

Model

SZLH 320

Application

Animal

Finished

Pellets

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

|---|---|---|---|---|---|---|---|---|

| Main Motor Power(Kw) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder Power(kw) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Conditioner Power(kw) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Ring Die Inner Diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 |

| Finished Pellets Diameter (mm) | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 |

| Production Output (TPH) | 1.0-1.5 | 3-4 | 5-6 | 10-12 | 15-16 | 20-22 | 30-33 | 38-40 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of animal feed pellet production.

Feeding and conditioning systems

The optimized conditioning system with inverter feeding system improves the safety, nutritional value and maturation of the raw material to a great extent. This improves the overall quality of the feed from the source and ensures healthy feeding.

Drive system

High-end Siemens industrial grade drive motor drives the drive shaft of RICHI animal feed pellet machine, which is more stable and durable than traditional belt drive. In the long run, this not only improves efficiency but also saves maintenance costs.

Structure and material

The body of the machine is made of high quality and high specification alloy steel, which is sturdy and durable, reduces resonance and runs stably. The parts that come into contact with the raw material are made of high grade stainless steel, which does not affect the raw material in any way and greatly improves corrosion resistance.

Control and Safety

Each feed pellet mill is equipped with an independent electric control system and safety stop function. It can not only avoid losses caused by perceived errors, but also effectively protect the pellet mill and subsequent production equipment.

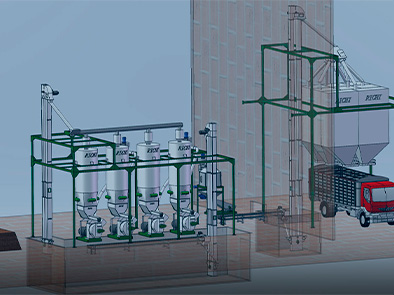

Discover our streamlined buying process that makes it simple and efficient for you to get a complete animal feed pellet production plant. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

HENAN RICHI MACHINERY CO.,LTD

Henan Richi Machinery Co., Ltd was founded in 1995. After nearly thirty years of development and expansion, RICHI Machinery has grown into a modern enterprise covering an area of 60,000 square meters and integrating independent research and development, production and sales.

The products involve feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveying equipment and engineering, steel structure engineering, silo, automation control technology and engineering, etc., and each product series has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

The system is fully automated and requires minimal labor. Customized pellet production solutions can be switched at the touch of a button in the control room for pelletizing a wide range of raw materials.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of animal feed plant do you want to establish?

How many tons per hour about this plant you want to build?

Where is this animal feed plant going to be built?

When do you plan to start the operation?

If you're planning to enter the animal feed game with a bit more scale than a backyard setup, the SZLH320 feed pellet mill is a sweet spot. It produces 3–4 tons of pellets per hour, which is ideal for growing farms or medium-sized feed factories. Unlike small machines that limit your capacity, this feed mill pellet machine gives you room to grow without jumping into industrial-size costs. We've seen it used successfully across Africa, Southeast Asia, and South America where farmers want to scale up their poultry or livestock operations without blowing the budget. It’s reliable, scalable, and backed by our 30+ years of on-the-ground installation experience. A solid starting point if you're serious about feed production.

Good question, and one we get a lot. The SZLH320 isn’t a giant, but it does need a bit more breathing room than smaller units. You’ll want a workspace with at least 30–50 square meters, ideally with a concrete floor and proper ventilation. Remember, it’s not just the animal pellet mill itself—you’ll also need space for raw material storage, mixers, maybe a cooler or crusher depending on your setup. Think of it like a mini feed processing line. If you’re setting this up on a farm or in a rural workshop, just make sure you have enough headroom and clear access for maintenance. We can help design the layout so you don’t waste space or time.

The main difference comes down to output and production scale. The SZLH320 feed pellet mill delivers around 3–4 tons per hour, putting it right in the middle of our range. Smaller models like the SZLH250 are great for beginners or small farms producing 1–1.5 tons/hour. If you’re aiming to feed thousands of animals daily or even sell feed commercially, the SZLH320 gives you more flexibility. It’s like the “Goldilocks” machine—not too big, not too small. Compared to bigger models (like SZLH420 or SZLH508), it’s easier to install, costs less upfront, and uses less power. If you’re stepping up from manual or semi-auto production, this machine is a great next move.

Pretty much anything in the animal feed world! The SZLH320 is a multi-purpose animal pellet mill, meaning it can handle feed formulas for poultry (like broilers and layers), pigs, cattle, sheep, goats, and even rabbits. We’ve had customers in Latin America using it to make dairy cow pellets, and others in Southeast Asia making poultry layer mash into pellets for improved feed efficiency. You can also switch die sizes to adjust pellet diameter depending on your animals. If you want help fine-tuning your formula for your region, we’re happy to guide you—we’ve done this in over 80 countries!

Yes, totally manageable—even if you’re new to this. We designed the SZLH320 to be user-friendly and low-maintenance, especially for farmers and first-time mill owners. It comes with a full manual, and our technicians offer on-site or remote training. Once you get the basics down (feeding materials, adjusting moisture, monitoring the die and roller wear), you’re good to go. Maintenance is simple: regular greasing, cleaning the ring die, and checking wear parts. And since this animal feed pellet machine for sale has a robust build, it doesn't break down easily—so you spend more time producing and less time fixing.

The machine is quite flexible. Most customers use local agricultural materials like corn, soybean meal, rice husk, wheat bran, cassava flour, and fish meal. You can even add vitamins, minerals, and premixes for balanced nutrition. The SZLH320 feed pellet mill has a conditioner that steams and softens the materials before pelletizing, which improves pellet quality. We've seen farms in Africa using maize and sunflower cake, while customers in Asia often include palm kernel meal. No matter your region, we can help you build a recipe that suits your animals and your budget.

The feed mill pellet machine price depends on configuration (basic machine vs. full production line with mixer, crusher, cooler, etc.), but it’s definitely a cost-effective investment. Compared to importing feed or buying commercial pellets, owning your own mill reduces your cost per ton significantly. In fact, many of our customers recover their investment in 1 to 2 years, especially if they produce extra feed to sell to neighbors or local farms. We’ll give you a detailed quotation with freight, installation, and parts, so you know exactly what you’re investing in.

Absolutely. We’re not just a manufacturer—we’re your long-term partner. When you purchase the SZLH320 animal feed pellet mill for sale, we provide:

Whether you're in Ghana, Colombia, Vietnam, or Poland, we’ve got experience installing in your type of environment. Our team knows how to handle voltage differences, local raw materials, and even climate-specific concerns.

The SZLH320 is the heart of your feed mill, but you’ll also need a few other pieces of equipment to get a full production line:

We help customers design these systems based on their needs and budget. Whether you're just starting or upgrading, we’ll recommend a layout that saves space, power, and time. With our 30+ years of experience, you’ll get a solution that works from day one.

100%. The SZLH320 feed pellet mill is widely used as a feed mill machine for poultry, especially in regions where chicken and duck farming are growing fast. It’s great for making layer feed, broiler feed, grower or starter pellets—and you can adjust the size of the pellets according to your poultry's age and breed. Because you control the recipe, you can make more nutritious feed than some mass-produced commercial brands. Many poultry farms use it to guarantee quality and save money. If you’re raising poultry and thinking long-term, this machine pays off quickly.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy