Frequency conversion feeding system, steam tempering system, double pressure roller pelletizing system, Siemens electronic control system, plus alloy steel forging body, these become the core of animal feed pellet production.

Brand

RICHI

Model

SZLH 350

Application

Animal

Finished

Pellets

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

|---|---|---|---|---|---|---|---|---|

| Main Motor Power(Kw) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder Power(kw) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Conditioner Power(kw) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Ring Die Inner Diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 |

| Finished Pellets Diameter (mm) | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 |

| Production Output (TPH) | 1.0-1.5 | 3-4 | 5-6 | 10-12 | 15-16 | 20-22 | 30-33 | 38-40 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of animal feed production.

Feeding and conditioning systems

The optimized conditioning system with inverter feeding system improves the safety, nutritional value and maturation of the raw material to a great extent. This improves the overall quality of the feed from the source and ensures healthy feeding.

Drive system

High-end Siemens industrial grade drive motor drives the drive shaft of RICHI animal feed pellet mill, which is more stable and durable than traditional belt drive. In the long run, this not only improves efficiency but also saves maintenance costs.

Structure and material

The body of the machine is made of high quality and high specification alloy steel, which is sturdy and durable, reduces resonance and runs stably. The parts that come into contact with the raw material are made of high grade stainless steel, which does not affect the raw material in any way and greatly improves corrosion resistance.

Control and Safety

Each feed pellet mill is equipped with an independent electric control system and safety stop function. It can not only avoid losses caused by perceived errors, but also effectively protect the pellet mill and subsequent production equipment.

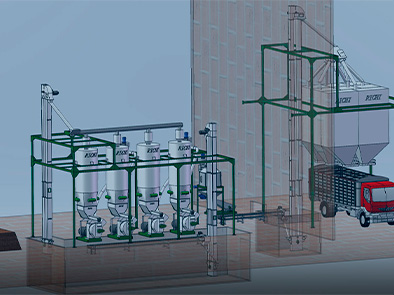

Discover our streamlined buying process that makes it simple and efficient for you to get a complete animal feed pellet production plant. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

HENAN RICHI MACHINERY CO.,LTD

Henan Richi Machinery Co., Ltd was founded in 1995. After nearly thirty years of development and expansion, RICHI Machinery has grown into a modern enterprise covering an area of 60,000 square meters and integrating independent research and development, production and sales.

The products involve feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveying equipment and engineering, steel structure engineering, silo, automation control technology and engineering, etc., and each product series has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

The system is fully automated and requires minimal labor. Customized pellet production solutions can be switched at the touch of a button in the control room for pelletizing a wide range of raw materials.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of animal feed plant do you want to establish?

How many tons per hour about this plant you want to build?

Where is this animal feed plant going to be built?

When do you plan to start the operation?

Absolutely—it’s actually one of the top choices for folks ready to move from small-scale feed mixing to real mid-level production. The SZLH350 feed pellet mill gives you 5-6 tons/hour, which is the sweet spot for businesses that want to grow but aren't ready for full industrial scale. Whether you're supplying feed to your own farm or looking to sell to neighbors or nearby cooperatives, this machine gives you enough capacity to build a profitable operation without overcomplicating things. It’s like upgrading from a motorbike to a pickup truck—more power, more load, but still manageable.

The SZLH350 is designed for mid-sized feed production, so it’s not too bulky, but it does need a bit of elbow room. Ideally, you want at least 60–80 square meters for a basic setup, including the pellet mill and supporting equipment like a grinder, mixer, and maybe a cooler. If you’ve got a small warehouse, old barn, or part of your farm building with a concrete floor—you’re good. We’ve helped set this up in chicken farms in Kenya, pig farms in Vietnam, and even cooperative mills in Brazil. You don’t need a factory; just a clean, solid, well-ventilated space with reliable power.

Not at all! While many customers use it as a poultry feed mill, the SZLH350 can handle feed for chickens, ducks, pigs, cows, sheep, goats, and more. It depends on your raw materials and die size (which we help you customize). We’ve had customers in Nigeria making broiler and layer feed, clients in Colombia making pig grower pellets, and even goat feed in Thailand. The flexibility of this pellet mill technology is what makes it great—it can adapt to your animals and your market.

That’s a common concern, and the short answer is: yes, it’s beginner-friendly. The controls are straightforward, and we include full training during installation—either on-site or by video support. Most customers pick it up in a day or two. Think of it like learning to use a rice mill or a thresher—once someone shows you the basics, you’re off and running. Plus, our team stays in touch to guide you remotely if needed. Whether you're in Cambodia or Cameroon, we make sure you're comfortable using your SZLH350 feed pellet mill from day one.

The SZLH350 feed pellet mill is built tough—solid steel frame, quality motors, and wear-resistant parts. But like any machine, it does need basic care. You’ll need to grease the bearings, check the rollers and die, and clean the feeder regularly. We supply all the spare parts, and replacements are affordable. We’ve designed it so that even a basic mechanic can handle most upkeep. A quick tip? Always clean the die after each shift—keeps it from clogging and helps it last longer. With regular TLC, this machine can run 8–10 years without major issues.

No need to import anything fancy. One of the biggest advantages of the SZLH350 feed pellet mill is that it can work with local raw materials—corn, rice bran, cassava powder, palm kernel cake, wheat bran, soymeal, fish meal—you name it. In Africa, many farmers use maize and groundnut cake. In South America, it’s often corn and soybean mix. Southeast Asia uses rice bran and palm oil residues. The key is having a grinder and mixer before the pelletizing step to get the right texture. We can help you build a balanced recipe based on what’s available in your area.

We get this one a lot. While prices vary depending on configuration and shipping, most customers agree it’s 100% worth it. Instead of buying commercial feed at rising prices, you can produce your own for a fraction of the cost. Plus, many clients start selling excess feed locally, creating a whole new revenue stream. Most pay off their investment in 12–24 months, depending on production volume. And since we’ve been doing this for 30+ years, we help you avoid common mistakes—making sure you get full value from day one.

You’ve got options. We offer the SZLH350 as a standalone pellet mill, or as part of a full turnkey feed production line. That includes the grinder, mixer, pellet mill, cooler, screener, and packaging system—all customized for your needs and space. If you're just starting, maybe the standalone is enough. But if you want to grow fast or supply other farmers, the full line gives you efficiency, better quality, and less labor. We’ve designed lines for cooperatives in Peru, poultry farms in Uganda, and commercial mills in Indonesia—every customer gets a solution tailored to their budget and goals.

Definitely. One of our biggest strengths is our global service network. We’ve shipped and installed pellet mills in over 80 countries, and we always make sure our customers are never left hanging. You get:

If you're in Africa or Southeast Asia, chances are we’ve worked in your area before. Even if you’re remote, we find a way to support you—because success stories fuel our reputation.

Great question. The SZLH350 feed pellet mill can handle 5-6 tons/hour, which is usually more than enough to support 400,000+ birds, especially if you're producing feed for 8 hours per shift.One ton of feed can supply roughly 10,000 broilers/day, depending on age and ration. So, for a size of 100,000 birds, we recommend the SZLH250 or SZLH320. Of course, if you are producing feed for sale in addition to supplying it to your own farm, then the SZLH350 is certainly sufficient and there is still room for growth. If you want to expand in the future, we can help you to upgrade to a larger model such as the SZLH420.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy