Frequency conversion feeding system, steam tempering system, double pressure roller pelletizing system, Siemens electronic control system, plus alloy steel forging body, these become the core of animal feed pellet production.

Brand

RICHI

Model

SZLH 420

Application

Animal

Finished

Pellets

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

|---|---|---|---|---|---|---|---|---|

| Main Motor Power(Kw) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder Power(kw) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Conditioner Power(kw) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Ring Die Inner Diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 |

| Finished Pellets Diameter (mm) | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 |

| Production Output (TPH) | 1.0-1.5 | 3-4 | 5-6 | 10-12 | 15-16 | 20-22 | 30-33 | 38-40 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of animal feed production.

Feeding and conditioning systems

The optimized conditioning system with inverter feeding system improves the safety, nutritional value and maturation of the raw material to a great extent. This improves the overall quality of the feed from the source and ensures healthy feeding.

Drive system

High-end Siemens industrial grade drive motor drives the drive shaft of RICHI animal feed pellet mill, which is more stable and durable than traditional belt drive. In the long run, this not only improves efficiency but also saves maintenance costs.

Structure and material

The body of the machine is made of high quality and high specification alloy steel, which is sturdy and durable, reduces resonance and runs stably. The parts that come into contact with the raw material are made of high grade stainless steel, which does not affect the raw material in any way and greatly improves corrosion resistance.

Control and Safety

Each feed pellet mill is equipped with an independent electric control system and safety stop function. It can not only avoid losses caused by perceived errors, but also effectively protect the pellet mill and subsequent production equipment.

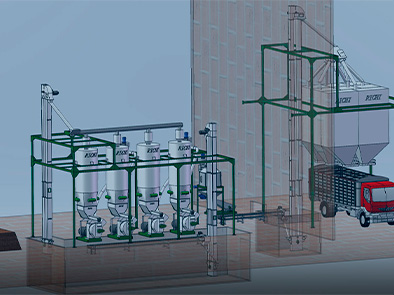

Discover our streamlined buying process that makes it simple and efficient for you to get a complete animal feed pellet production plant. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

HENAN RICHI MACHINERY CO.,LTD

Henan Richi Machinery Co., Ltd was founded in 1995. After nearly thirty years of development and expansion, RICHI Machinery has grown into a modern enterprise covering an area of 60,000 square meters and integrating independent research and development, production and sales.

The products involve feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveying equipment and engineering, steel structure engineering, silo, automation control technology and engineering, etc., and each product series has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

The system is fully automated and requires minimal labor. Customized pellet production solutions can be switched at the touch of a button in the control room for pelletizing a wide range of raw materials.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of animal feed plant do you want to establish?

How many tons per hour about this plant you want to build?

Where is this animal feed plant going to be built?

When do you plan to start the operation?

If you're planning to go big with feed production, then yes—the SZLH420 feed pellet mill is a solid match. It pumps out around 10–12 tons per hour, which makes it perfect for large farms, commercial feed plants, or cooperatives that supply multiple buyers. Whether you're producing feed for chickens, pigs, cattle, or even selling feed to local farmers, this is industrial-level stuff. It’s not for hobby setups—it’s for folks ready to take things to the next level. We've helped businesses in Kenya, Vietnam, Brazil, and Poland build entire operations around this model.

For high-capacity feed production, you’ll want to plan carefully. The SZLH420 itself is sizeable, but the full setup usually includes feed crushers, mixers, conveyors, a pellet cooler, and sometimes a bagging machine. At a minimum, you’re looking at 500 square meters for a streamlined operation. In addition, due to our feed production process, complete feed mills have requirements in terms of height, which usually require 10-15 meters or even more. Therefore you need to determine if your plant has a height restriction. Ideally, you want a proper plant layout with separate zones for raw materials, processing, and finished products. Don’t worry—we help you with layout planning based on your site. We’ve done installs in rural warehouses, farm-based mills, and even urban industrial parks, so we’ll adapt to your space.

This machine is a workhorse—it can produce poultry, cattle, pig, sheep, and goat feed, and even certain fish feed (sinking type). One of the biggest advantages of the SZLH420 is that it handles different recipes and materials without a fuss. Many clients in Southeast Asia use it for layer and broiler feed. In South America, customers often make pig and beef cattle feed. Just change the die size and tweak the recipe, and boom—you’re producing exactly what your animals need. If you’re supplying feed to multiple farms, this flexibility gives you a serious competitive edge.

You don’t need an engineering degree to run it—but for a machine this powerful, having a trained operator is a big plus. That’s where we come in. With every installation, we include on-site training or video support to teach your team how to use the system, adjust parameters, and troubleshoot. Once your team gets the hang of it, operation becomes routine—just like driving a bus instead of a motorcycle. The control panel is straightforward, and our documentation is available in multiple languages. We’ve trained teams in Africa with no prior experience who are now running like pros.

The SZLH420 feed pellet mill is built for versatility. You can use corn, wheat bran, soybean meal, rice husks, palm kernel cake, cassava flour, cottonseed meal, and more—whatever’s available in your local agri-market. Our customers in Nigeria use maize and groundnut cake; in Colombia, it’s soy and wheat bran; in the Philippines, rice bran and copra meal. The only thing to watch is moisture content and grind size—materials should be well-mixed and properly crushed before pelletizing. We also help you fine-tune the formulation to meet your nutritional goals.

A full feed pellet mill solution built around the SZLH420 usually includes:

For what it delivers, the SZLH420 is a solid investment. Pricing depends on whether you're buying just the pellet mill or a full production line. But here’s the thing: when you compare it to the cost of buying commercial feed long-term, the math adds up fast. One of our customers in Tanzania said they recovered the investment in under 18 months by producing their own feed and selling excess locally. Plus, this is heavy-duty equipment—built to last. We’re talking 10+ years of service with proper maintenance. You get ROI and peace of mind.

Great question—and the answer is: very reliable. The machine is made from high-grade carbon steel, with a robust gearbox and precision bearings. It’s designed to handle tropical climates, dusty barns, and power fluctuations. In fact, we’ve installed SZLH420s in humid regions of Southeast Asia and hot, dry zones in Africa. The secret is simple: install it right, service it regularly, and use good quality materials. And don’t worry—we walk you through proper setup and give you a maintenance checklist tailored to your environment.

You’re not just buying a machine—you’re gaining a partner. With over 30 years of global experience, we know what long-term support looks like. Here’s what you get:

Whether you’re in Bolivia, Uganda, or Malaysia, we’re just one message away. That’s one reason customers stay with us for the long haul—we don’t disappear after the sale.

The SZLH420 feed pellet mill is a powerful choice for a commercial setup. If you’re producing 80–100 tons per day, it will definitely hold its own. Many of our clients build an entire feed mill around a single SZLH420 and then expand by adding a second one as business grows. However, if you’re planning massive volume from day one—say 200+ tons/day—you might consider pairing it with a larger model like SZLH508. Either way, the SZLH420 is often the first step into serious, scalable high-capacity feed production—and it’s one you won’t regret.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy