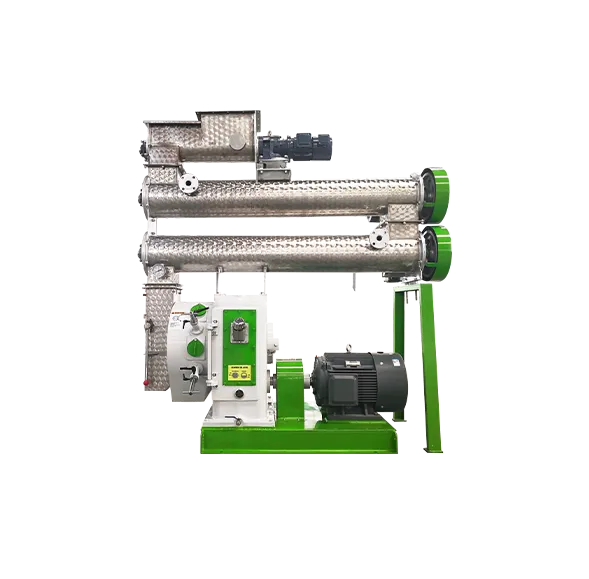

Frequency conversion feeding system, steam tempering system, double pressure roller pelletizing system, Siemens electronic control system, plus alloy steel forging body, these become the core of animal feed pellet production.

Brand

RICHI

Model

SZLH 558

Application

Animal

Finished

Pellets

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

|---|---|---|---|---|---|---|---|---|

| Main Motor Power(Kw) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder Power(kw) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Conditioner Power(kw) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Ring Die Inner Diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 |

| Finished Pellets Diameter (mm) | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 |

| Production Output (TPH) | 1.0-1.5 | 3-4 | 5-6 | 10-12 | 15-16 | 20-22 | 30-33 | 38-40 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of animal feed production.

Feeding and conditioning systems

The optimized conditioning system with inverter feeding system improves the safety, nutritional value and maturation of the raw material to a great extent. This improves the overall quality of the feed from the source and ensures healthy feeding.

Drive system

High-end Siemens industrial grade drive motor drives the drive shaft of RICHI animal feed pellet mill, which is more stable and durable than traditional belt drive. In the long run, this not only improves efficiency but also saves maintenance costs.

Structure and material

The body of the machine is made of high quality and high specification alloy steel, which is sturdy and durable, reduces resonance and runs stably. The parts that come into contact with the raw material are made of high grade stainless steel, which does not affect the raw material in any way and greatly improves corrosion resistance.

Control and Safety

Each feed pellet mill is equipped with an independent electric control system and safety stop function. It can not only avoid losses caused by perceived errors, but also effectively protect the pellet mill and subsequent production equipment.

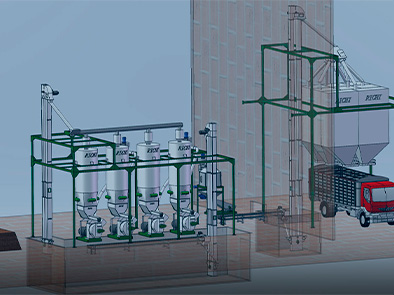

Discover our streamlined buying process that makes it simple and efficient for you to get a complete animal feed pellet production plant. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

HENAN RICHI MACHINERY CO.,LTD

Henan Richi Machinery Co., Ltd was founded in 1995. After nearly thirty years of development and expansion, RICHI Machinery has grown into a modern enterprise covering an area of 60,000 square meters and integrating independent research and development, production and sales.

The products involve feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveying equipment and engineering, steel structure engineering, silo, automation control technology and engineering, etc., and each product series has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

The system is fully automated and requires minimal labor. Customized pellet production solutions can be switched at the touch of a button in the control room for pelletizing a wide range of raw materials.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What kind of animal feed plant do you want to establish?

How many tons per hour about this plant you want to build?

Where is this animal feed plant going to be built?

When do you plan to start the operation?

Absolutely. The SZLH558 feed pellet mill is tailor-made for heavy-duty feed production, especially for businesses that are either supplying feed at an industrial scale or planning a multi-farm integration model. With a capacity of 20–22 tons per hour, it's built for serious output. We’ve installed this machine in several investment-backed projects—one client in Brazil supplies both their poultry farms and sells to external markets, running this mill nearly round the clock.

If you're building a serious feed business or expanding a commercial feed plant, then yes—the SZLH558 feed pellet mill is built for that job. With an output of 20–22 tons per hour and a double-layer conditioner, it's designed to handle heavy-duty feed production with excellent pellet quality. We’re not talking about small farm use here—this is for factories supplying regional markets, poultry integrations, or livestock feed distribution. If you're making business decisions at a company level or working with partners or investors, this is the level of equipment that delivers real ROI and scalability.

The double-layer conditioner is one of the key upgrades that sets this model apart. It gives feed more retention time for heat and moisture, which translates to better cooking and more stable pellets. That means less powder, higher feed digestibility, and improved animal performance. For investors and factory owners, that also means fewer complaints from clients, higher product quality, and stronger brand reputation. One of our customers in Vietnam told us the pellet durability index (PDI) jumped significantly after switching to this durable pellet mill with dual conditioning. It's like the difference between fast food and slow-cooked—it just performs better.

Great question, especially for commercial planners. To run this machine properly, you’ll need a facility with at least 1,000-2,000 square meters, especially if you're operating a full production line: grinding, mixing, pelletizing, cooling, screening, bagging, and raw material silos. You’ll also want to plan for logistics space—truck access, loading bays, storage. We've helped clients in Kenya and Colombia design compact yet efficient layouts for the SZLH558 line. If you’re building a new factory, we can even support with CAD layout drawings and recommend building specs. You won’t be left guessing—we walk with you from blueprint to production.

The ROI depends on your market, but in most cases, we’ve seen break-even within 1.5 to 2.5 years. Let’s say you’re producing 400 tons/day and saving $30–50 per ton compared to purchasing feed—that's a huge operational saving. Plus, the ability to control your formulation and cost structure is a game-changer. One investor in West Africa recovered their costs in just 18 months by selling feed to partner farms and distributing to smallholders. When paired with a smart distribution model, this heavy-duty feed production system becomes not just a cost-saver, but a profit generator.

The feed pellet mill price for the SZLH558 varies depending on configuration, but let’s talk about value: this is not just a machine—it’s an asset. With its output, many of our customers recoup their investment in 12–24 months, especially if they're replacing expensive commercial feed or supplying contract farms. One client in Egypt who switched to in-house pelletizing using the SZLH558 saved over 30% in feed costs and started selling surplus feed within six months. When you calculate feed production per ton and the value of stable, high-quality pellets, this machine makes a lot of sense commercially.

While it’s a heavy-duty unit, the SZLH558 is surprisingly operator-friendly. We’ve designed the controls to be intuitive, and our standard support includes on-site training or remote video commissioning, depending on your location. You’ll want at least 3–5 trained workers to run the line efficiently—including operators for raw material handling, pelletizing, and bagging. Maintenance is mostly routine checks, lubrication, and scheduled part replacements. We provide a full maintenance guide and spare parts plan, and we’re available 24/7 for tech support. If you’ve run any factory machinery before, your team will adjust quickly.

The price of the SZLH558 feed pellet mill varies depending on whether you want the standalone machine or a full turnkey line. For a complete system—including grinder, mixer, conditioner, cooler, screener, dust control, and bagging—you’re looking at a serious but scalable investment. But we break it down clearly for you, line by line. No hidden costs, no guesswork. Our team will also help you compare options: semi-auto vs. full-auto, bulk handling vs. manual bagging, etc., so you get a solution that fits your budget and vision. And remember—this isn't a short-term buy, it’s a 10-15 year asset.

Absolutely, and in fact, we recommend it for high-volume plants. The SZLH558 can be integrated into fully automated feed production lines with batching systems, PLC control cabinets, touch screen monitoring, and even real-time data tracking for feed performance. In South America, we’ve helped several clients automate everything from raw material intake to final packaging—cutting labor needs in half and improving product consistency. Automation isn't just a luxury; it's a smart move when you're producing 500+ tons daily.

Definitely. We’ve installed machines in 80+ countries, and logistics is part of our core service. We handle everything from container packing and port shipment to customs documents and insurance. For installation, we offer:

We’ve done this in hard-to-reach rural towns in Kenya and busy industrial zones in Mexico. If you’re investing in a durable pellet mill, we make sure the entire process—from shipping to startup—is smooth and hassle-free.

100%. That’s one of the smartest things about choosing the SZLH558—it fits well into both a standalone line or a modular multi-line setup. Many clients start with one line, and as the business grows, they add a second or third SZLH558 or upgrade with bigger silos, bulk loading systems, or automated packaging lines. We design your system with future scalability in mind, so expansion later doesn't require starting over. Whether you’re in Ghana, Vietnam, or the US Midwest, we’ll help you build a feed production line that grows with your ambitions.

If you need further information, please contact us

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy