FAQs on pellet making machine, pellet mill, or other related equipment. Common problems when using the pellet machine and how to solve it.

This 6tph biomass pellet plant business plan is suitable for industrial construction projects and was provided by Richi Machinery to customer(Sanming Yuanfu Biomass Technology Co., Ltd) in Fujian Province, China in 2017.

1. Origin of the project

The development of biomass pellets is restricted by factors such as raw materials, climate, production cost, etc., and the Chinese government has not made enough efforts to encourage its development, and the development speed has not been fast. However, as the environment continues to deteriorate, people's awareness of environmental protection continues to increase, and natural resources are non-renewable, people are increasingly favoring "low-carbon, environmentally friendly" biomass pellet fuels. In particular, biomass pellet fuel, with its simple production process, high product density, high calorific value, high combustion efficiency, and environmental protection, has made people's energy demand more focused on biomass pellet fuel.

This project is located in Jishan Park, Jiangle Economic Development Zone, Jiangle County, Fujian Province. The project land leases a local factory vacant land for construction and production. The land is industrial land. The total investment of the project is about 9 million U.S. dollars (62 million RMB). , The equipment investment is 1.2 million US dollars, the total land area is 1000m², the main construction area is 1000m², and the main production scale is an annual output of 15,000 tons of biomass pellet fuel.

The total investment of this 6 tons per hour biomass materials wood straw powder pellet manufacturing plant project is 9 million USD, of which 5.3 million is circulating funds, and 4.7 million is construction funds, including: equipment purchase (around 1.1 million USD) and installation costs, engineering construction costs, real estate maintenance costs, management fees during construction, and unforeseen costs.

2. Geographical location

This project is located in Jishan Park, Jiangle Economic Development Zone, Fujian. Fujian Jiangle Economic Development Zone Jishan Industrial Park is located in the northeastern suburbs of Jiangle County, with a planned total land area of 1200m², surrounded by mountains. The project location has convenient transportation and flat terrain, and there are no rare protected species and historical sites in the surrounding area.

The project leases the land of Sanming Yuanfu Biomass Technology Co., Ltd. The north side of the project is the storage tank area of Sanming Yuanfu Biomass Technology Co., Ltd., the east side is the sewage treatment station of Sanming Yuanfu Biomass Technology Co., Ltd., and the south side is open space and the west side. It is the office and living area of Sanming Yuanfu Biomass Technology Co., Ltd. The surrounding area of Sanming Yuanfu Biomass Technology Co., Ltd. is planned to be used for construction of industrial projects. The north side is the central heating project of the park, the west side is Hongyan Chemical, the east side is Tonghai Nickel Industry Company, and the south side is adjacent to unbuilt land. Open space, there are no nature reserves and cultural relics protection units in the surrounding area of the project.

3. Project engineering

| Name | Main construction content | |

| 1 | Main project | Biomass pellet production line for wood straw pellets |

| (1) | Production workshop | Covers an area of 1000 square meters |

| 2 | Public and auxiliary projects | |

(1) |

Water supply | Municipal water supply in the park |

| (2) | Power supply | Supplied by the park's power supply pipe network |

| 3 | Environmental protection projects | |

| (1) | Wastewater treatment | ①Domestic sewage enters the park sewage treatment plant after being treated by sewage treatment facility; ②The boiler's wastewater is recycled, and a circulating pool is set up, and only a small amount of evaporation is needed. |

| (2) | Exhaust gas treatment | ①The process dust is treated by a set of bag filters and discharged through a 15m high exhaust cylinder; ②The boiler exhaust gas is treated by a set of bag filters and discharged through a 35m high chimney. |

| (3) | Noise control | Plant sound insulation, equipment foundation vibration reduction |

| (4) | Solid waste treatment | ①Set up household garbage bins in the factory area, and after unified collection, entrust the sanitation department to clean and transport them daily; ② Production scraps and collected dust production are collected and reused for production. |

| 4 | Storage and transportation engineering | |

| (1) | Finished product storage yard | Set up a finished product storage area in the production workshop, covering an area of 200 square meters |

| (2) | Raw material storage yard | Set up a raw material storage area in the production workshop, covering an area of 200 square meters |

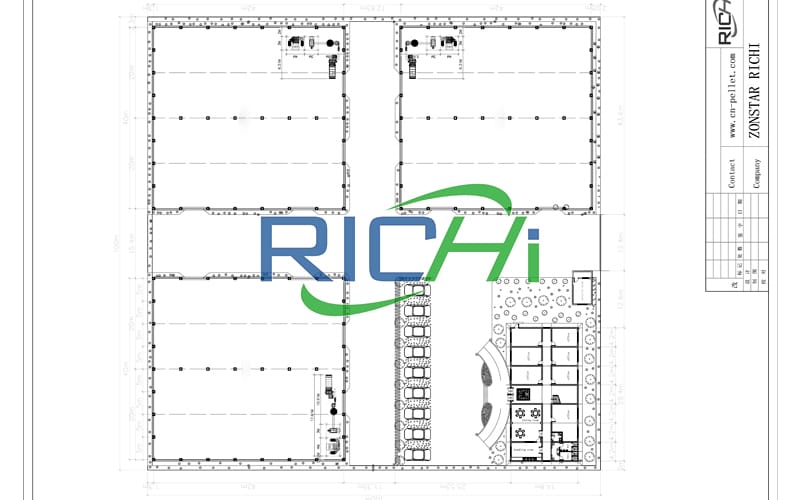

4. General layout

The 6 tons capacity turnkey wood staw pellet production factory area is composed of finished product warehouse, production workshop, boiler room, waste gas treatment facility bag filter, etc. The direction of the factory production workshop from northwest to southeast is raw material storage yard, granulation workshop, waste gas treatment facility bag filter, and finished product warehouse. ,Boiler Room. The overall layout of the plant is compact, the process flow is smooth, and the overall layout is relatively reasonable.

5. Main production equipment needed in 6 tons per hour complete biomass wood sraw pellet line

| Number | Equipment | Quantity |

| 1 | Belt conveyors | 2 |

| 2 | Buffer bin | 1 |

| 3 | Ring die biomass wood straw pelletizer machine | 11 |

| 4 | Screw conveyor | 1 |

| 5 | Finished product warehouse | 1 |

| 6 | Double-tube bag vacuum cleaner (with side suction hood) | 2 |

| 7 | Electric control | 11 |

| 8 | 4 ton/hour biomass boiler | 1 |

6. Consumption of main raw and auxiliary materials and energy consumption

(1) Use of raw and auxiliary materials

This project makes full use of the leftover wood scrap powder, straw powder, and lignin powder produced by surrounding enterprises to process biomass molding fuel (particles). The project will produce 15,000 tons of biomass molding fuel per year and require various types of biomass each year. Leftovers are about 15,000 tons.

Biomass pellets: It uses pressure rollers and ring molds to perform cold compact molding of crushed biomass, forestry waste and other raw materials under normal temperature conditions. The density of raw materials is generally 0.1-0.13t/m3, and the density of pellets after molding is 1.1-1.3t/m3, which is convenient for storage and transportation, and greatly improves the combustion performance of biomass.

| Biomass materials name | Annual consumption (t/a) |

| Wood scrap powder | 9600 |

| Straw powder | 3400 |

| Lignin powder | 2000 |

(2) Main energy and water consumption consumption

| Serial number | Annual consumption |

| Water | 1526 t/a |

| Power | 270000 kwh/a |

| Biomass fuel materials | 2200 t/a |

7. Complete 6 tons per hour biomass energy pellet production process flow

(1) Wood scrap powder, straw powder, and lignin powder are mixed and dried and fed into the feeding bin, and then conveyed by a screw conveyor into the pelletizer for compression and granulation molding. Finally, the finished pellets are packaged in packaging bags. Warehousing.

(2) Drying: raw wood scrap powder, straw powder, lignin powder, etc. will be dried using a 4t/h biomass boiler to provide steam after entering the plant;

(3) Feeding: mix the purchased raw materials wood scrap powder, straw powder, and lignin powder into the feed bin;

(4) Granulation: The mixed raw materials are sent to the granulator through the screw conveyor, and the finished product is formed by extrusion molding. The extrusion process is a physical process without any adhesives and no chemical reaction. Except for the connection of the feeding screw auger and the discharge port, the production equipment and the material conveying process are all sealed.

(5) Packing: After granulating by the granulator, the products are packed and packed into storage.

This project will build a 4t/h biomass test boiler, whose main function is to provide steam for the drying process of the project, and the excess energy will be used for production gas.

8. Analysis of industrial policy compliance

This project mainly uses outsourcing peripheral companies to produce scrap wood scrap powder, straw powder, and lignin powder for biomass pellet production. The project belongs to the encouraged category by comparing with the "Industrial Structure Adjustment Guidance Catalog (2017) (Revised)" :Agriculture and forestry, 48: Deep processing and product development of three leftovers, and the production of biomass-forming particulate fuel complies with the “Policies to Promote the Accelerated Development of the Biological Industry” (Guobanfa [2014] No. 45). , Potato, Jatropha, Pistacia chinensis, light bark tree, Aronia fruit and plant fiber The development of bio-energy such as liquid fuel production using non-food crops as raw materials and biomass compact fuels. "The construction of this project is conducive to increasing employment opportunities, and promoting regional economic development, in line with national industrial policies and environmental protection policies.

9. Environmental feasibility analysis

(1) Industrial policy compliance and cleaner production

This project belongs to the encouraged project in the "Industrial Structure Adjustment Guidance Catalog (2011 Edition) (Revised)". This project complies with the country's current industrial policies and environmental protection policies. The raw and auxiliary materials and energy used in this project basically meet the requirements of cleaner production. The production technology adopted by the project is relatively advanced. The production equipment is made by a domestic manufacturer with its own technology, which can realize continuous automated production. The "three wastes" generated by the project can be discharged up to the standard after corresponding treatment measures are taken, and the solid waste generated can be comprehensively utilized or properly disposed of. In summary, this project meets the requirements of cleaner production.

(2) Reasonability of site selection

The project is located in Jishan Park, Jiangle Economic Development Zone. The land used for the project is industrial land and leased workshops. The surrounding environment of the project is of good quality, conforms to the environmental function zoning, has a certain environmental carrying capacity, and restricts the project Not much. After implementing various environmental protection measures, the project can achieve up-to-standard emissions and have little impact on the environment. Therefore, the site selection of this project is feasible.

(3) Status of Environmental Quality

Water environment: The water quality of the surrounding water body Jinxi meets the "Surface Water Environmental Quality Standards" (GB3838-2002) in Class III water quality standards; Atmospheric environment: The current ambient air quality in the area where the project is located is relatively good, which can reach the "Ambient Air Quality" Quality Standard (GB3095-2012) in the requirements of the secondary standard; Acoustic environment: the environmental noise of the project location meets the Class 3 standard of the Acoustic Environmental Quality Standard (GB3096-2008).

10. Environmental impact analysis

(1) Wastewater

The boiler steam and water used in the project are recycled and not discharged. The main wastewater of the project is the domestic wastewater of the employees. The employees of the project rely on the existing public facilities of Sanming Yuanfu Biomass Technology Co., Ltd. for toilets, meals and lodging. The generated domestic sewage is treated in the septic tank of Sanming Yuanfu Biomass Technology Co., Ltd. and enters the plant area. After the pretreatment of the sewage treatment station reaches the third-level standard in Table 4 of the "Integrated Wastewater Discharge Standard" (GB8978-1996), it enters the park sewage treatment plant for unified treatment. The tail water of the sewage treatment plant in the Jishan Industrial Park will be discharged after it reaches the first level B standard of the Pollutant Discharge Standard for Urban Sewage Treatment Plants (GB18918-2002). The project wastewater has a relatively small impact on the surrounding water environment.

(2) Exhaust gas

★Dust

①Organized: through the collection of dust generated by the main production equipment of each process, the collected dust will be uniformly processed by a bag filter and discharged through a 15m high exhaust cylinder. The dust volume is 0.0855t/a, and the emission rate is 0.0855t/a. It is 0.0356kg/h, and the emission concentration is 7.125mg/m3. The organized dust emission of the project can meet the requirements of the maximum allowable emission concentration limit of 120mg/m3 in the "Comprehensive Emission Standard of Air Pollutants" (GB16297-1996), and the organized dust emission of the project can meet the emission standards.

②Unorganized: The unorganized dust emission of the project is 0.45t/a, and the emission rate is 0.1875kg/h. According to the forecast, the maximum landing concentration of unorganized dust emission is 0.1472mg/m3, which can meet the emission standards. Through strengthening management and workshop ventilation, through natural diffusion, the project has no unorganized dust emission exceeding the standard point. The project needs to set a 50m sanitation protection distance, and there are no sensitive targets such as residential areas within the sanitation protection distance. The impact on the surrounding atmospheric environment is small.

★Boiler flue gas

The project boiler is planned to be equipped with a bag filter to treat the boiler flue gas, with a treatment efficiency of 99%, but the dust removal device has no ability to reduce nitrogen oxides and sulfur dioxide. The treated exhaust gas is discharged through a 35m high chimney. The emission concentration and emission rate of project boiler exhaust gas and dust (9.92mg/m3, 0.0045kg/h), nitrogen oxide emission concentration (155.67mg/m3, 0.935kg/h), sulfur dioxide emission concentration (51.89mg/m3, 0.312kg) /h), mercury and its compounds (0.0305mg/m3, 0.00018kg/h) can meet the "Boiler Air Pollutant Emission Standard" (GB13271-2014) Table 2 limit standard for coal-fired boilers.

(3) Noise

After the noise of the production equipment is attenuated by the sound insulation of the workshop wall and the distance, the noise emission value of the factory boundary can reach the standard of category 3 in the "Environmental Noise Emission Standard for Industrial Enterprises" (GB12348-2008), that is, daytime ≤65dB (A).

(4) Solid waste

The solid waste generated by the project has basically been rationally utilized and comprehensively disposed of.

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy