FAQs on pellet making machine, pellet mill, or other related equipment. Common problems when using the pellet machine and how to solve it.

This is a business proposal of 8t/h reasonable design new miscellaneous wood peanut shell straw pellet manufacturing plant for biomass fuel production,which is provided in 2017 by Richi Machinery.

1. Origin of the 8 tons per hour wood peanut shell pellet making line project

The comprehensive utilization of agricultural and forestry waste recycling is an industry strongly supported by the state. The implementation of agricultural and forestry waste solidification and molding fuel projects will replace traditional petrochemical energy with clean and renewable green energy, which can not only reduce local towns and rural areas on petrochemical energy Dependence on economic development can reduce the pressure on energy supply caused by economic development, and while effectively protecting the ecological environment, it can also produce considerable economic and social benefits. In order to accelerate the development and implementation of the construction of "beautiful villages", protect the ecological environment, and use agricultural and forestry wastes rationally and efficiently, customer has decided to invest 8,000,000 yuan(around 1,200,000USD) to build a biomass pellet fuel project with production output of 8 tons per hour. The project address is located in Yanzhou District. 260m southeast of Sizhuting Village, Xinglongzhuang Street.

2. Industrial policy compliance

(1) According to the "Industrial Structure Adjustment Guidance Catalogue (2011 Edition)" (2013 revision), it can be known that this project belongs to the encouraged category. "1. Agriculture and Forestry Article 20: Return of Crop Straw to Field and Comprehensive Utilization (Ensilage) , Straw ammoniated cattle breeding, returning to the field, straw biogas and pyrolysis, gasification, cultivating edible fungi, solidified fuel, straw man-made board, straw cellulose fuel ethanol, development and utilization of non-grain feed resources, etc.). Project"; it also belongs to the encouraged category "Article 28. Comprehensive Utilization of Environmental Protection and Resource Conservation: Industrialization of Renewable Resources Recovery and Utilization"; therefore, the construction of this project conforms to the national industrial policy.

(2) The "Restricted Land Project Catalog (2012 Edition)" and the "Prohibited Land Project Catalog (2012 Edition)" jointly issued and implemented by the Ministry of Land and Resources and the National Development and Reform Commission do not impose restrictions or prohibitions on this project According to the regulations, this project can be regarded as a permitted project.

According to the above analysis, this project is an industry encouraged to develop. At the same time, the construction of this project meets the requirements of relevant laws and regulations and the requirements of the local environmental protection department. Therefore, the construction of this project is in line with the requirements of national and local industrial policies.

3. Project overview

This project with an annual output of 20,000 tons of biomass pellet fuel is a new project. The project site is located 260m southeast of Sizhuting Village, Xinglongzhuang Street, Yanzhou District. The main construction content includes biomass pellet fuel production facilities, auxiliary facilities and public works, etc. , All production workshops, offices, etc. are leased. The project has a total investment of 8,000,000 yuan, including environmental protection investment of 260,000 yuan, a total area of 3000 square meters, a total construction area of 2071 square meters; the date of commissioning is September 2018, and the project will have an annual production scale of 20,000 tons of biomass pellet fuel. The number of employees is 10, the annual production time is 300 days, the annual production time is 7,200 hours, and the investment payback period is 2.5 years.

4. Customized 8t/h peanut shell biomass wood pellet processing line project composition

| Engineering category | Engineering name | Engineering Content |

| Structural Engineering | Production workshop | Tower 1, 1F, with a construction area of 2000m2. Set up one crusher (chipper), one crusher, three biomass pelletizers, and four belt conveyors. Mainly used for chipping, crushing, granulating and other processes. |

| Supporting Engineering | Raw material area | This project sets up a raw material area in the southwest corner of the production workshop, covering an area of 200m2. |

| Finished product area | This project sets up a finished product area in the southeast corner of the production workshop, covering an area of 200m2. | |

| Office | The office is located on the west side of the production workshop, covering an area of 50m2, mainly used for production and operation management. | |

| Public Engineering | Water supply | The water for the proposed project is provided by the running water pipe network of Xinglongzhuang Street. |

| Drain | The proposed project adopts the rain and sewage diversion system, and constructs rainwater pipe network and sewage pipe network separately. | |

| Powered by | Provided by the street power supply station, the annual electricity consumption is about 2.8 million kW·h. | |

| Environmental Engineering | Exhaust | Crushing dust, granulating dust, and crushing (chip) dust: After being collected by their respective air collecting hoods, they are treated by a secondary bag filter with a treatment efficiency of 99%. After treatment, they are discharged through a 15m high exhaust tube.Unorganized dust: Strengthen the ventilation and exhaust measures in the workshop. |

| Waste water | The domestic sewage is treated in the septic tank and then transported out to make agricultural fertilizers without being discharged. | |

| Noise | Measures such as shock absorption, sound insulation and noise reduction. | |

| Solid waste |

Dust collection by dust collector: after collection, it will be sold for disposal. Domestic garbage: collected and disposed of by the sanitation department. |

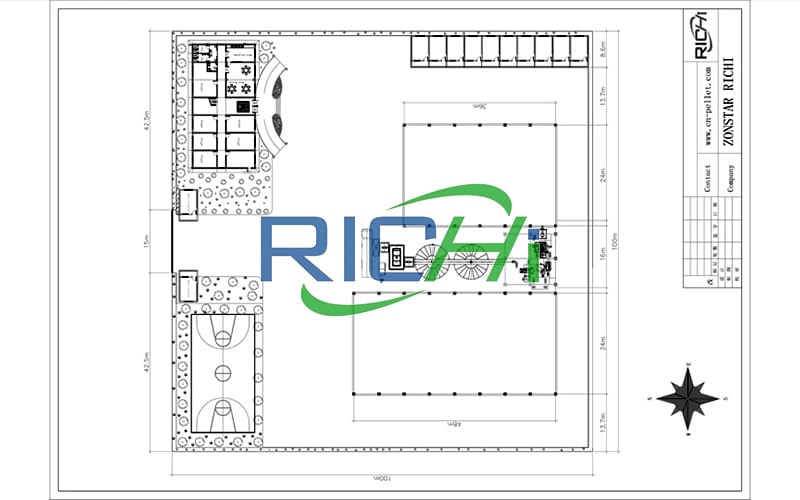

5. General layout in this 8 tons capacity wood pellet plant

(1) Layout plan

The 8tph complete biomass wood peanut shell pellet production line project is located at 260m southeast of Sizhuting Village, Xinglongzhuang Street, Yanzhou District. The leased factory area covers an area of about 3000m², including 2000m²for production workshops, 50m² for offices, 21m² for power distribution rooms, and 929m² for other roads and greening. The production workshop is located on the north side of the factory. The office is located on the west side of the production workshop. The finished product area and the raw material area are set inside the production workshop. There is no need to build structures. The leased production workshop has a total length of 50m and a width of 40m. The project site is flat. According to the project's geographic location, topography and meteorological conditions, the project has carried out a more reasonable distribution of the 8t/h biomass pellet factory buildings. The plant area of this project is divided into production area and living area according to functions, and the specific distribution is as follows:

①Production workshop: lease a workshop with an area of 2000m², located on the north side of the factory.

②Office and living area: It is mainly an office, located on the west side of the production workshop, with an area of 50m², used for production and operation management.

③Road system planning: starting from the requirements of convenient transportation, reasonably arrange the internal roads of the factory to form a complete road system. Due to the small flow of people and goods, relying on the original roads and entrances and exits can meet the production needs of this project.

(2) Rationality analysis

①According to the regional wind frequency map and meteorological data, the dominant wind direction in the project area is S (southern wind), and the living area is not in the downward wind direction from its dominant wind, and the exhaust gas generated during the production process is small, which has a greater impact on the office and living area small.

②The main noise of this project mainly comes from the noise generated by the operation of crushers, pulverizers, pelletizers, belt conveyors, etc., because the noise sources are all arranged in the production workshop, and all noise sources adopt certain shock absorption , After the sound insulation measures, the impact on the surrounding environment is small.

③The facilities in the production area of this project are reasonably arranged in accordance with the technological process, and the material transportation is short and quick, which can meet the needs of the material flow, and at the same time can meet the purpose of rapid material transportation.

④The functional areas of the project area are clearly arranged to meet the requirements for non-production and irrelevant personnel to enter the production area.

⑤This project has a compact layout, which can meet the requirements of saving land.

Through the above analysis, the division of the project is clear, the overall layout of the project satisfies the smoothness of the process flow, and reflects the convenience of material transportation, which simplifies the transportation of materials in the plant area and facilitates production; After the treatment measures, the impact of production dust and equipment operation noise on the office and living area is relatively small; the layout of the general plan is reasonable.

(3) Main buildings of the 8t/h new design fuel pellet production line project

| Name | Length×width×height | Building area (m2) | Structure | Quantity |

| Production workshop | 50m×40m×8.0m,1F | 2000 | Steel structure | 1 |

| Office | 10m×5m×3.5m,1F | 50 | Steel structure | 1 |

| Switch room | 7m×3m×3.5m,1F | 21 | Steel structure | 1 |

| Total:2071 m2 | / | / | ||

6. Main raw and auxiliary materials and power consumption

| Number | Name | Annual consumption |

| 1 | Miscellaneous wood | 16610 t/a |

| 2 | Peanut shells | 2300 t/a |

| 3 | Straw | 1150 t/a |

| 4 | Water | 150 m3/a |

| 5 | Electricity | 2.8 million Kw·h/a |

7. The main equipment of the 8t/h new type peanut shell biomass wood pellet production line project

| Serial number | Equipmet name | Model | QTY |

| 1 | good wood chipper shredder with ce | W-Disc-800 | 2 |

| 2 | wood sawdust making machine | SFSP66*80a | 2 |

| 3 | biomass wood pellet mill with CE | MZLH series | 4 |

| 4 | belt conveyor | / | 4 |

| 5 | dust collector | / | 5 |

8. Public works in in the 8t/h biomass wood pellet plant

(1) Power supply: The power supply of this project is provided by the Xinglongzhuang Street Power Supply Office. The annual power consumption of this project is about 2.8 million kW·h. A new 250KVA transformer is installed to meet the needs of production and life.

(2) Water supply: The water for this project is provided by the tap water pipe network of Xinglongzhuang Street, relying on the tap water pipe network system of the leased workshop, which can meet the needs of production and living.

The water used in this project is mainly domestic water, and the total water consumption is 150m3/a. The project has a staff quota of 10, and the water consumption quota is 50L/person·d, and the annual water consumption is 150m3/a.

9. 8TPH good quality peanut shell biomass wood pellet line project process flow

According to the actual requirements of the customer, the processing flow of this project is relatively simple. Natural cooling is adopted and no packing scale is configured. The finished pellets will directly enter the warehouse, and then be loaded and transported to leave the factory. The process of this project: purchase miscellaneous wood, peanut shells, and straw, which can be stored after crushing, crushing and granulating.

(1) Chipping process

Chipping: Use a high quality wood shredder chipper to cut large pieces of miscellaneous wood into small pieces;

(2) Crushing process

Crushing: After crushing a large piece of raw material to a size of 600mm by a hing capacity wood peanut shell hammer mill grinder, it is directly transported to the wood pellet granulator;

(3) Granulation process

Pelletizing: the crushed raw materials are fed into the ring die wood peanut shell pellet press for pelleting;

(4) Finished product

Include finished pellet products into finished product area.

10. Reasonable analysis of project site selection

This project is located 260m southeast of Sizhuting Village, Xinglongzhuang Street, Yanzhou District. The land for this project is construction land, which meets the planning requirements. This project leases the already built production workshop and does not build new buildings; there is no bad geology in the occupied area and is suitable for building a new wood and peanut shell fuel pellet production factory; after effective pollution prevention measures are taken during the production and operation of the project, pollutants are discharged up to the standard and meet the environmental and health protection distance requirements; The environmental impact is small; the project is surrounded by guaranteed water, electricity, heating supply, convenient transportation and other conditions, and there are no scenic spots, ecological fragile zones, etc., so the site selection of the project is reasonable.

11. Pollutant discharge situation

(1) Exhaust gas emission situation

①Organized waste gas: crushed dust, granulated dust, crushed (chip) dust

The pulverized, granulated, and crushed (chip) dust of this project is collected by their respective air collecting hoods and introduced into a secondary bag filter for treatment. After treatment, they are uniformly introduced into a 15m high exhaust cylinder for high-altitude discharge. After treatment, the emission concentration meets the requirements of "Shandong The emission requirements of the key control area (Yanzhou District) in Table 2 of the Provincial Comprehensive Emission Standard of Air Pollutants (DB37/2376-2013), and the emission rate meets the requirements in Table 2 of the Comprehensive Emission Standard of Air Pollutants (GB16297-1996) Relevant requirements of secondary standards.

②No organization: no dust collected

The amount of uncollected dust in this project is 0.6t/a. The ventilation and exhaust measures of the workshop should be strengthened, and the greening around the production workshop should be strengthened. After taking the above-mentioned measures, the emission concentration of dust at the boundary of the project meets the requirements of the concentration limit of unorganized emission monitoring in Table 2 of the "Comprehensive Emission Standard of Air Pollutants" (GB16297-1996).

(2) Wastewater discharge situation

The domestic sewage of the employees of this project is treated in a septic tank and then transported for composting to realize resource utilization and not discharge. The impact on the surrounding surface water environment quality is small.

(3) Lighter groundwater pollution

The main aspects of the project that will affect groundwater are the sewer network and septic tank storage links. After the construction and production of this project have adopted anti-seepage measures for all structures and floors in the production and storage areas of this project, the impact of the construction and production of this project on the quality of the groundwater environment is relatively small.

(4) Noise compliance

The noise sources generated during the production process of this project mainly include the operating noise of crushers, pulverizers, granulators, belt conveyors, induced draft fans and other equipment. By selecting low-noise equipment and reasonably arranging noise sources, and taking basic measures such as vibration reduction and sound insulation according to the location and characteristics of the noise sources, the daytime (no production at night) noise at the plant boundary of this project meets the requirements of "Environmental Noise Emissions at the Boundary of Industrial Enterprises" "Standard" (GB12348-2008) Class 2 functional zone standard requirements, which have little impact on the surrounding acoustic environment quality.

(5) Zero discharge of solid wastes

The solid waste generated in the production process of this project mainly includes dust collection by dust collectors and domestic waste of employees. After various solid wastes are collected and sold outside, and collected and disposed by the environmental sanitation department, general industrial solid waste treatment measures And the disposal plan meets the requirements of the "General Industrial Solid Waste Storage and Disposal Pollution Control Standard" (GB18599-2001) and the amendments, and will not adversely affect the surrounding environment.

(6) Low environmental risk level

There are risks such as fire and environmental pollution accidents during the operation of this project. During the operation, various safety rules and regulations must be implemented in strict accordance with national technical specifications and operating procedures, and monitoring and management must be strengthened to avoid fire accidents. After earnestly implementing the safety measures to be taken by the project and the safety facilities and safety countermeasures proposed in the evaluation, the impact of the project accident on the surroundings is at an acceptable level.

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy