FAQs on pellet making machine, pellet mill, or other related equipment. Common problems when using the pellet machine and how to solve it.

How much does it cost to start a 15-30 ton per day (2-4 tons per hour) cattle sheep feed mills?Generally speaking, price of capacity of 15-30 ton per day cattle sheep feed pellet processing plant costing 15000-120000USD.

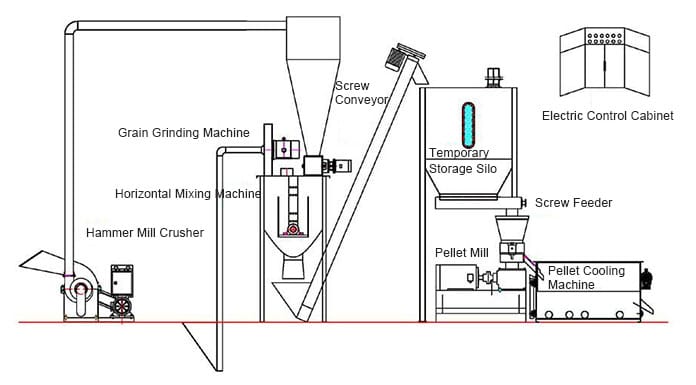

1.Stages of 15-30 ton per day cattle sheep feed production and its equipments

Richi Machinery supply turnkey solutions for 15-30 ton per day sheep and cattle feed production line: from design, project management, process engineering to procurement local manufacturing, installation, commissioning, after sales service, and financing (price & cost control). We study every details of the pelleting solution, so that to ensure you get the best ruminant sheep cattle feed milling equipment, best service and best plan.

The major operations involved in the cattle feed plant are: raw materials preparation,crushing,mixing,pelleting and packaging.

(1)Raw and auxiliary materials are first charged into silos and tanks where they are made ready for further processing. They are then processed by primary crusher. Crushed materials are further separated by means of a sieve, and then stored in the assorting tanks according to the kind of raw materials.

(2)The raw materials are then mixed by means of an animal feed mixer. In this process, fatty ingredients are added to the materials in order to raise the nutritional value of the feed. The feed obtained from the mixer is blended with molasses

(3)Assorted animal feed that is crushed into fine particles is further formed into pellets by a ring die type cattle sheep feed pellet milling machine.

(4)Cooling is a process of removing heat. As we know during conditioning we add heat and moisture and also through palleting process heat generates by extrusion process.

(5)The end of process in 15-30 ton per day small capacity cattle sheep feed making plant is bagging also called packing. After screening the finished products are filled in to bags.

Small size 15-30 ton per day cattle sheep feed pellet production plant makes 4-8 mm diameter cattle or sheep feed pellets. The last pellet length can be adjusted.

| Technical Parameters of Main Equipment of 2-4TPH Feed Production Plant for Cattle and Sheep | |||

| Item | Name | Model | Power (KW) |

| Part 1. Raw material receiving& crushing system | |||

| 1-001 | Grass hammer mill crusher | SW50-28 | 15 |

| 1-111 | cattle feed making hammer mill | SFSP66*60 | 55.0 |

| Part 2. Mixing System | |||

| 2-207 | Feeder for additive | ||

| 2-208 | machine that mix cattle feed | SLHS1.0 | 11 |

| 2-210 | Scraper Conveyor | TGSU20 | 3 |

| Part 3. pelleting system | |||

| 3-308 | pellet making machine for cattle feed | SZLH350 | 57.95 |

| 3-310 | Pellet Cooler | SKLN3 | 1.50 |

| Part 4. Packing system | |||

| 4-402 | Rotary Screener | SFJH80*2d | 2.20 |

| 4-409 | Auto Packing Scale | 10-50KG | 1.50 |

| 4-410 | Stitch conveyor | 1.50 | |

| Part 5. Auxiliary Equipment System | |||

| 5-506 | Steam Supplying System | ||

| 5-507 | Oil adding System | 2.2 | |

| 5-508 | Oil Adding Tube | ||

| 5-509 | Calabash Crane | 3.0 | |

| Contact Richi Machinery to Get Complete solution of Small Scale Cattle Sheep Feed Production | |||

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy