FAQs on pellet making machine, pellet mill, or other related equipment. Common problems when using the pellet machine and how to solve it.

Today Richi Machinery will share you a business plan of 18t/h poultry pig feed mill and 2t/h expanded corn production line project in China, this is a customized poultry pig feed factory project with 18 tons per hour, there is also a small expanded corn production line added. This 20t/h animal feed factory project was completed in 2018 and is now running well.

1. Origin of the 18t/h poultry pig feed mill and 2t/h expanded corn production project

Complete feed is also called pellet feed, which can be fed directly without reprocessing. The complete feed is composed of protein feed (such as fish meal, beans and meal, etc.), energy feed (such as corn, wheat bran, etc.), rough feed (used only in low-standard batches) and additives (excluding grain and its supplements). Additives other than the product are called additives) a four-part compound feed. This type of feed product is also called a complete ration compound feed. It is usually divided into various models according to the feeding object (animal type, age, production purpose, etc.).

This kind of feed can fully meet the nutritional needs of the feeding objects, and the user does not need to add any additional nutritive feeding materials, but must pay attention to choosing a full-price compound feed that is consistent with the feeding objects. The feed contains energy, protein, mineral feed and various feed additives. The various nutrients are complete, sufficient in quantity, and proportioned to meet the production needs of feeding animals. It can be directly used for production and generally any other feed does not need to be supplemented.

Expanded corn is also called expanded corn flour, which refers to the starch paste of corn under the combined effects of moisture, heat, mechanical shear, friction, kneading and pressure difference. It can be used as the main raw material for food and feed. Expanded corn has a loose, porous and uniform structure. , The texture is soft and the starch gelatinization degree is improved. It not only has good color, aroma and taste, but also improves the nutritional value and digestibility. It can especially improve the weaning stress problem of young animals. Therefore, the use of puffed raw materials It is an effective way to promote the growth of piglets.

In view of the large market potential of full-price feed and expanded corn, combined with its own capital and technical advantages and the advantages of human resources around the project area, the client company decided to invest in the construction of an annual feed and expanded corn project.

The project was completed in April 2018. It has been completed and put into production, and has formed an annual production scale of 50,000 tons of poultry and pig feed and expanded corn (annual production of 45,000 tons of full-price feed and 5 million tons of expanded corn). The annual sales income can be 80 million yuan and the annual profit is 2 million yuan. yuan. Not only that, the completion and commissioning of this project can also solve the employment problem of 15 people, which has good economic and social benefits.

2. Overview of 18t/h poultry pig feed mill business and 2t/h expanded corn production business project

This 18tph poultry pig feed mill and 2t/h expanded corn project is a new project. The factory is located 410 meters southwest of Xibuyin Village, Baotai Town, Pingyi County, Linyi City. The main construction content is feed and expanded corn production facilities, auxiliary facilities and public works.

The animal pig poultry feed mill cost is 4.8 million yuan, including environmental protection investment of 400,000 yuan, with a total area of 3564m2 and a total construction area of 3762m2. The project was completed and put into production in April 2016, and has formed an annual output of 50,000 tons of pig poultry food and extruded corn (complete feed 45,000 t/a, expanded corn 5 000 t/a), and an annual sales income of 8,000 RMB,the annual average profit is RMB 2 million; the number of employees is 15; the annual production time is 300 days, 4800 hours, and the investment payback period is 2 years.

| Serial number | Name | Unit | QTY |

| 1 | Production scale | ||

| (1) | Complete livestock feed | t/a | 45,000 |

| (2) | Extruded corn | t/a | 5,000 |

| 2 | Annual operating days | d | 300 |

| 3 | Consumption of main raw materials and auxiliary materials | ||

| (1) | Corn | t/a | 30000 |

| (2) | Soybean meal | t/a | 10000 |

| (3) | Corn germ meal | t/a | 5000 |

| (4) | DDJS | t/a | 5000 |

| (5) | Dicalcium Phosphate | t/a | 500 |

| (6) | Soybean oil | m3/a | 100 |

| (7) | Methionine | t/a | 5 |

| (8) | Stone powder | t/a | 200 |

| (9) | Salt | t/a | 10 |

| 4 | Utility consumption | ||

| (1) | Water | m3/a | 6180 |

| (2) | Electricity | kW·h/a | 500000 |

| (3) | Gas | million m3/a | 45.5 |

| 5 | Factory-wide quota | People | 15 |

| 6 | Plant area | ㎡ | 3564 |

| 7 | Total construction area | ㎡ | 3762 |

| 8 | Financial Evaluation | ||

| (1) | Total project investment | Ten thousand yuan | 480 |

| ① | Investment in fixed assets | Ten thousand yuan | 400 |

| ② | Working capital | Ten thousand yuan | 80 |

| (2) | Annual sales revenue | Ten thousand yuan | 8000 |

| (3) | Total production cost | Ten thousand yuan | 7800 |

| (4) | Average annual total profit | Ten thousand yuan | 200 |

| (5) | Payback period | Year | 2 |

3. Project engineering content of 2t/h expanded corn and 18t/h poultry feed mill factory

| Engineering category | Engineering name | Engineering Content | Remarks |

| Structural work | Production workshop | One, 1F, construction area of 1386m2, steel frame structure, inside is divided into boiler room, raw material storage area, production area, etc. Among them, the previous process and equipment of corn crushing (including) are shared by poultry pig feed and extruded corn. | An annual output of 45,000 tons of complete feed and 5,000 tons of expanded corn. |

| Storage and Transportation Engineering | Warehouse | One, 1F, building area of 1980m2, steel frame structure, the interior is divided into small material production area, finished product storage area, small material preparation room, etc. Mainly used for storage of finished products and small materials. | |

| Supporting project | Office building | One building, 2F, with a construction area of 396m2, is mainly used for office and business management. | |

| Public works | Water supply | The water source for this project is groundwater, which is supplied by a 20m deep self-provided well in the plant area. The water used is mainly domestic water and boiler water. | One-time water consumption is 6180m3/a. |

| Drain | The plant area implements rain and sewage diversion, and newly builds a rainwater pipe network and a sewage pipe network. Rainwater is finally discharged to Lubu River through nearby drainage ditches; The sewage is mainly domestic sewage, which is treated in a septic tank and then transported for compost without being discharged. | ||

| Powered by | It is powered by the local power supply and has a 400kVA transformer. | The annual electricity consumption is 500,000 kW·h. | |

| Heating | The heat supply for this project is provided by a 1t/h natural gas steam boiler. The fuel is natural gas and is provided by the local gas company. | ||

| Environmental Engineering | Exhaust | Boiler exhaust gas: 1 15m exhaust pipe (8#). | Discharge |

| Corn unloading dust: air collecting hood (collection efficiency 90%) + bag filter (1 set, dust removal efficiency 99%) + 1 15m exhaust tube (1#) | Discharge | ||

| Corn crushing dust 1. Puffed corn cooling dust 1. Puffed corn crushing dust 1: Negative pressure collection + bag filter (1 set, dust removal efficiency 99%) + 1 15m exhaust tube (2#) | Discharge | ||

| Complete feed dust: air collecting hood (collection efficiency 90%) + bag filter (2 sets, dust removal efficiency 99%) + 1 15m exhaust tube (3#) | Discharge | ||

| Corn crushing dust 2. Puffed corn crushing dust 2. Complete feed crushing dust, full-price feed ingredients mixed dust: negative pressure collection + bag filter (4 units, dust removal efficiency 99%) + 1 15m exhaust pipe ( 4#) | Discharge | ||

| Expanded corn cooling dust 2: negative pressure collection + cyclone dust collector (1 set, dust removal efficiency 85%) + 1 15m exhaust tube (5#) | Discharge | ||

| Complete feed pelleting cooling dust: negative pressure collection + cyclone dust collector (1 set, dust removal efficiency 85%) + 1 15m exhaust tube (6#) | Discharge | ||

| Small material feeding dust, mixed dust of small material ingredients: air collecting hood (collection efficiency 90%) + bag filter (2 units, dust removal efficiency 99%) + 1 15m exhaust tube (7#) | Discharge | ||

| Waste water | The domestic sewage is treated in a septic tank and then transported for compost without being discharged. | Resource utilization | |

| Noise | Measures such as shock absorption, sound insulation and noise reduction. | Discharge | |

| Solid waste | Raw material sieve residue: Sanitation and transportation; | zero emission | |

| Raw material waste packaging: take-out waste recycling station; | |||

| Non-conforming product: reused in production; | |||

| Dust collected by dust collector: reused in production; | |||

| Domestic waste: The sanitation department collects and bury the waste in a unified manner. | |||

| Waste reverse osmosis membrane: Sanitation and transportation. |

4. Product plan of 2t/h expanded corn and 18t/h animal poultry feed factory

| Serial number | name | Annual output (t/a) |

| 1 | complete feed | 45000 |

| 2 | extruded corn | 5000 |

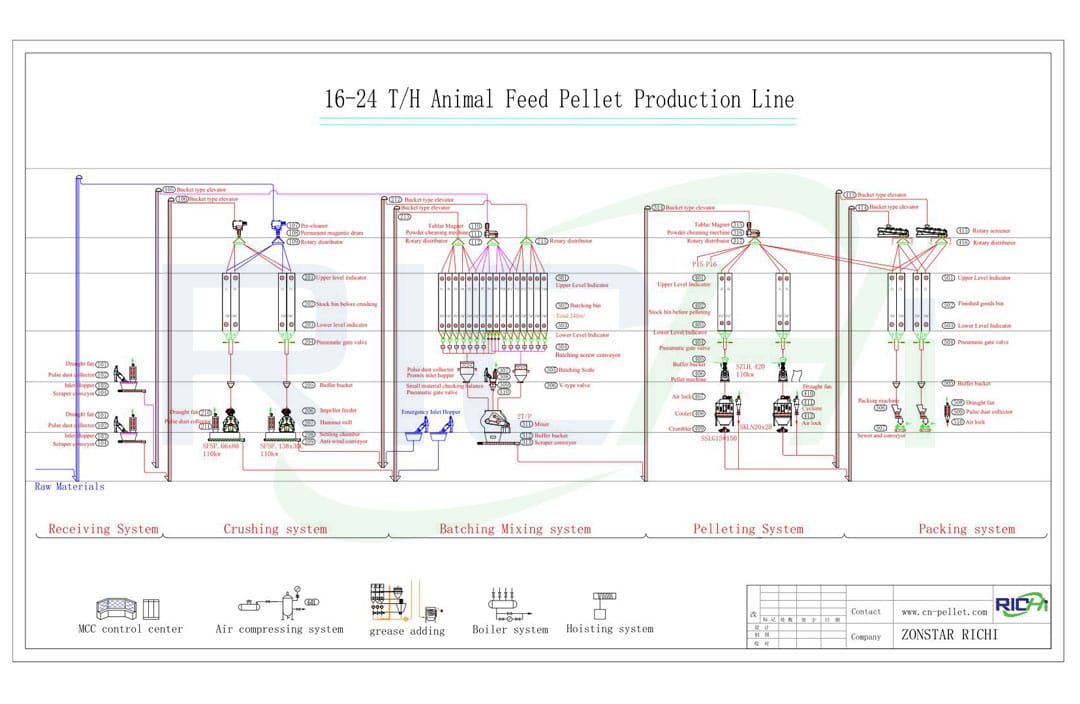

5.Complete 2t/h expanded corn and 18t/h poultry feed mill design

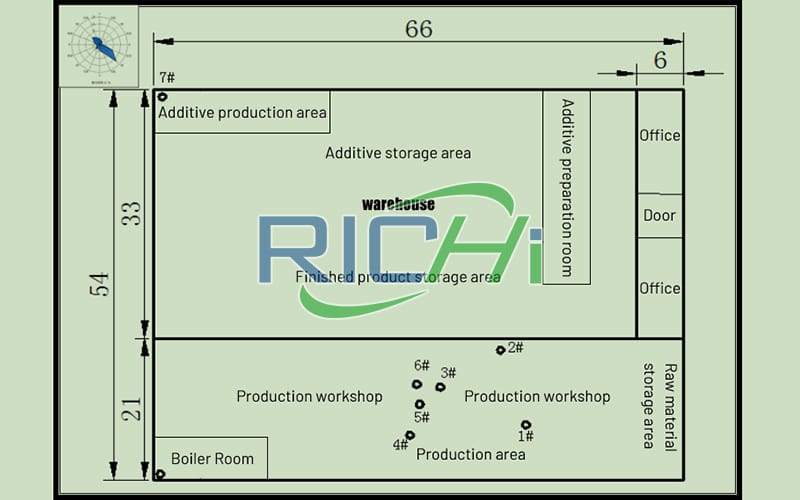

(1)Turnkey project 2t/h expanded corn and 18 tons capacity poultry feed mill plant layout

The project site is rectangular, with a width of 54m from north to south and a maximum of 66m from east to west. The topography of the project site is flat. The main buildings include 1 production workshop, 1 warehouse, and 1 office building. According to the project's geographic location, topography and meteorological conditions, the 20 tons per hour animal feed production project has carried out a more reasonable distribution of the factory buildings. The function of the 18t/h poultry animal feed manufacturing factory area of this project is mainly production area and office area.

①Production area: The production workshop is located in the west of the factory area, and the warehouse is located in the north of the east side of the factory area.

② Office area: Located on the north side of the eastern part of the plant, it is mainly an office building.

③Road system planning: starting from the requirements of convenient transportation, reasonably arrange the internal roads of the factory to form a complete road system. Since the flow of people and goods in this project is usually small, there is a common import and export for people and goods in the middle of the first floor of the east office in the south of the plant, which can ensure the smooth transportation of product production and goods.

(2)Rationality analysis of this 20t/h poultry pig animal feed mill line

①According to the regional wind frequency map and meteorological data, the dominant wind direction in the project area is SE (southeast wind), and the office area is not located in the downwind direction of the production area. Exhaust gas from the production area of the project will affect the office area little after strict control measures are taken.

②The noise generated by this project mainly comes from the operating noise of sieving machines, animal feed crushing machines, animal feed mixers, extruders, animal feed pelleting machine, balers, palletizers, fans, pumps and other equipment, because the noise sources are all arranged in the inside the workshop and far from the office area, the noise source has little impact on the office area.

③The facilities in the animal feed production area are reasonably arranged in accordance with the technological process, and the material transportation is short and quick, which can meet the needs of the material flow and the purpose of rapid material transportation.

④The layout of each functional area of this project is clearly defined, which can meet the requirements of non-production and irrelevant personnel to enter the production area.

⑤The layout of this project is compact, which can meet the requirements of saving land.

6.Poultry feed mill machinery and expanded corn production equipments for 18t/h poultry food plant & 2tph expanded corn plant

| Serial number | Livestock feed machine name | QTY | Remarks |

| 1 | Corn grinder machine | 2 | Corn crush |

| 2 | Expanded Corn Crusher | 2 | Expanded corn crush |

| 3 | Electric animal poultry feed mill grinder | 1 | Crushing of complete feed ingredients |

| 4 | poultry feed pellet making machine | 1 | Granulation |

| 5 | Baler | 2 | Package |

| 6 | Extruder for corn | 2 | Puffing |

| 7 | Air compressor | 1 | Gas source |

| 8 | Premix mixer | 1 | Mixing |

| 9 | poultry feed mixer machine | 2 | Mixing |

| 10 | Screening equipment | 1 | Filter |

| 11 | Palletizer | 1 | Temporary storage |

| 12 | Oil storage tank | 1 | Oil storage (capacity 1t) |

| 13 | Corn storage | 2 | Store |

| 14 | Forklift | 2 | Transport |

| 15 | Fan | Several | Draw the wind |

| 16 | 1T/H natural gas steam boiler heating | 1 | Heat |

| 17 | Soft water preparation system | 1 | Soft water preparation |

7. Public works of 2t/h expanded corn and 18t/h poultry feed mill business project

(1) Power supply: The electricity used in this project is provided by the local power supply bureau. The 10kV power supply branch line outside the factory leads to a 400kVA transformer in the factory area and transforms it to 380V/220V for the power consumption units of this project. The average power load is 104.17kW, and the annual power consumption is about 500,000 kW·h.

(2) Water supply: The water source for this project is self-provided well water. The water used in this project is mainly boiler soft water treatment equipment and staff domestic water. The total primary water consumption is about 6180m3/a.

(3) Heat supply: The heat supply for this project is provided by a 1t/h steam boiler in the plant area, the fuel is natural gas, and the local gas company provides the heating capacity of 455,000 m3/a.

8. Complete 2t/h extruded corn and 18t/h pig poultry feed mill production process

This project is a feed and expanded corn production project. The products are full price feed and expanded corn. The raw material of expanded corn is corn; the raw material of full price feed is corn, soybean meal, corn germ meal, stone powder, calcium hydrogen phosphate, methionine, salt, soybean oil, DDJS, etc.; the main production process is as follows:

(1) Production process of expanded corn

①Receipt of raw materials

Bulk corn and other raw materials are mainly received by automobile, and the raw materials are unloaded to the unloading pit after being weighed by a dump truck with a loadometer.

②Screening

Impurities in feed ingredients such as corn not only affect the quality of feed products, but also directly affect feed processing equipment and personal safety. In severe cases, the entire equipment can be damaged and affect the smooth progress of feed production, so it should be removed in time. The cleaning equipment is mainly screening. According to the difference in particle size, width, thickness, etc. of the material particles, one part of them will pass through the sieve surface to become the under-sieve, and the other part will remain on the sieve surface as the over-sieve, thereby making feed and impurities Separation, to achieve the purpose of removing impurities, or to separate feeds of different sizes and shapes for classification processing. The screening equipment removes large and long sundries such as straw, straw, hemp rope, paper pieces, soil blocks, corn leaves, corn cobs and other sundries in the raw materials. The screening process is completely airtight, and the screening materials are lifted into the silo.

③Warehousing

The screened raw materials are lifted by a hoist into the silo, and a dust filter device is installed on the top of the silo, and the dust generated by the falling of the material during the lifting process is filtered by the filter device.

④Smash

The corn kernels in the warehouse to be crushed enter the crusher through the impeller feeder. Two crushers are installed in this process. Work efficiency: part of the crushed corn enters the extruder to produce expanded corn, and part of the corn and soybean meal and other materials enter the large crusher to be further crushed to produce full-price feed.

⑤Puffing

The method of corn puffing in this project is wet puffing. Corn puffing is a starch gelatinization process under the combined effects of moisture, heat, mechanical shear, friction, kneading and pressure difference. The corn puffing heat source of this project is the steam produced by the natural gas steam boiler. When the corn flour is mixed with steam, the starch particles begin to absorb water and expand. When passing through the puffing cavity, the rapidly rising temperature and the kneading of the spiral blades accelerate the absorption of water by the mesh bag starch particles. , The crystal structure begins to disintegrate, the hydrogen bond breaks, and the expanded starch grains begin to rupture and become a viscous melt.

Due to the instantaneous pressure drop at the exit of the extruder, the instantaneous loss of steam (moisture) makes a large amount of expanded starch The granules disintegrate and the starch gelatinizes. High temperature, high pressure and mechanical shearing make the starch gelatinization more thorough than the starch produced by other processing methods. Generally, the gelatinization degree can reach 80%-100%. Compared with the conventional cooking process, the plant cell wall can be broken. The starch chain is shorter, which improves digestibility more effectively. There are many factors affecting corn puffing, mainly moisture, puffing temperature, puffing pressure difference and mechanical shearing force in the cavity.

⑥ Cooling of extruded material

In the puffing process, the high temperature and high humidity steam is introduced and the material is extruded to generate a lot of heat, which makes the temperature and humidity of the puffed particles higher. Under such conditions, adhesion and mildew will occur during temporary storage. The moisture must be reduced to below 14%, and the temperature must be lowered to below 8°C higher than the air temperature. Air cooling is used for project cooling. The extruded material is cooled by the air sent by the fan. The moisture and dust generated during the cooling process are passed through Shakron. The dust collector is discharged outside after treatment.

⑦Smash

The extruded material in the warehouse to be crushed enters the crusher through the impeller feeder, and the crushed pellets are conveyed by the screw conveyor and lifted to the temporary storage warehouse by the bucket elevator. This process is equipped with 2 pulverizers, and the particle size after pulverization is about 2-3mm. The purpose of pulverization is to increase the specific surface area of the feed, increase the utilization rate of the animal to the feed, increase the contact area of digestive enzymes to the raw material, and reduce the animal's intake The energy consumption of mastication in the process is beneficial to increase the feed reward; the material is crushed with a crusher and then sieved, and the sieved material is returned to the original crusher for crushing again.

⑧Packing

The finished product is transported to the finished product temporary storage warehouse, and then measured and packaged by the baler. The finished product warehouse is airtight. Because the expanded corn product is pellets, the pellet packaging process generates less dust.

(2) Small material/premix feed production process

①Feeding

Stone powder, dicalcium phosphate, methionine, salt and other small materials are transported to the next step through the feeding port through the scraper.

② Ingredients and mixing

Ingredients refer to the various ingredients of the feed formula, which are mixed according to the specified weight ratio, and processed so that every small part of the whole, even a feed, has the same ingredient ratio as the formula requires. This project uses a high-efficiency mixer, with a short mixing cycle, and the coefficient of variation of mixing uniformity is less than or equal to 5%. The materials enter the mixer after being accurately configured by weighing according to the scientific formula. After a reasonable and scientific mixing time, the materials enter the baler after being evenly mixed.

③Packing

In order to facilitate the subsequent production of ingredients, the evenly mixed small materials are measured and packaged by the baler.

(3) Production process of complete poultry pig feed

①Feeding

★Soybean meal, crushed corn, corn germ meal, DDJS and other raw materials are input through the feeding port, and then conveyed by a screw conveyor, and the bucket elevator is lifted to the next step.

★After the small materials are put in through the powder feeding port, they are conveyed by a screw conveyor and lifted by a bucket elevator to the next step.

★Soybean oil, etc. are directly transported from the storage tank to the batching process;

②Crushing

The pellets in the silo to be crushed enter the pulverizer through the impeller feeder, and the crushed pellets are conveyed by the screw conveyor and lifted to the batching silo by the bucket elevator. The purpose of crushing is to increase the specific surface area of feed, improve the utilization rate of feed by animals, and increase the effect of digestive enzymes on raw materials.

The contact area is reduced; the energy consumption of chewing during the feeding process of the animal is reduced, which is beneficial to increase the feed remuneration; the quality of the subsequent processes is improved and the work efficiency is improved.

③ Ingredients and mixing

Ingredients refer to the various components of the feed formula, which are mixed according to the specified weight ratio, and processed so that each small part of the whole, even a feed, has the same component ratio as the formula requires. When batching, the materials and small materials are mixed in a certain proportion, and the batching accuracy is less than 0.3%. Using a high-efficiency mixer, the mixing cycle is short, and the mixing uniformity variation coefficient is less than or equal to 5%. According to the scientific formula, the materials enter the mixer through a microcomputer and weighing accurately. After a reasonable and scientific mixing time, the microcomputer controls the material to enter the silo to be granulated through the buffer bucket, scraper conveyor, bucket elevator, and distributor.

④Extrusion and granulation

Before entering the animal pig poultry feed pellet making machine, it needs to be tempered. The tempering must be steamed into the material to directly contact and mix and moisten the material. After the tempering is uniform, it will drop to the granulator for granulation by extrusion. The granular feed formed by compacting and extruding a single raw material or compound mixture through mechanical action is called pelleting. The purpose of pelleting is to make finely divided, dust-prone, poorly palatable and difficult-to-ship feed into pellets using the heat, moisture and pressure during the pelleting process.

Compared with powdered feed, pelleted feed has the following advantages: improve feed digestibility; reduce animal picky eaters; make storage and transportation more economical; pelletizing generally increases the bulk density of powdered feed by 40% to 100%; avoids feed ingredients Automatic grading, reducing environmental pollution; killing Salmonella in animal feed. The steam is provided by a natural gas-fired boiler.

⑤Cooling

During the pelleting process, the high temperature and high humidity steam is introduced and the material is extruded to generate a lot of heat, so that when the pellet feed comes out of the pelletizer, the water content reaches 16%-18%, and the temperature is as high as 75℃ -85. ℃, under this condition, the pellet feed is easy to deform and break, and it will also cause adhesion and mildew during storage. The moisture must be reduced to below 14%, and the temperature must be lowered to below 8℃ higher than the air temperature. The project is cooled by wind Cold, the dust generated during the cooling process is discharged outside after being treated by the cyclone dust collector.

⑥Sieving

After the pellet feed is processed by the crushing process, a part of powder clots and other unqualified materials will be produced. Therefore, the crushed pellet feed needs to be sieved into products with neat particles and uniform sizes. The finished granular material is conveyed to the grading screen by the elevator, and the grading screen is a two-layer screen. Large sundries, primary products and other large particles on the sieve are collected through the trash discharge port and recycled to the cooling process. The intermediate sieve is the qualified finished product through the flow tube to the finished product warehouse, and the powder and other small particles under the sieve Reflux directly to the granulation process. This process is all airtight. After being concentrated and mixed, the powdered feed product enters into the powder sieve for screening, the oversieve returns to the crushing process, and the undersieve enters the finished product warehouse as qualified products. This process is all airtight.

⑦Packaging

The finished product is transported to the finished product temporary storage warehouse, and then is packaged and metered and packaged. The finished product warehouse is airtight. Because the powder and fine materials have been screened during the screening process, the amount of dust generated during the packaging process of the pellets is small.

9. Processes that will cause pollution

(1) Waste gas: The waste gas generated during the production process of this pig poultry feed project is mainly corn unloading dust, silo blanking dust, cooling dust, crushing dust, feeding dust, ingredient mixing dust, packaging dust, production process (puffing, manufacturing) Odor and boiler exhaust gas generated by granulation, cooling, screening, packaging).

(2) Wastewater: The wastewater from the boiler soft water treatment equipment of this feed manufacturing project is directly discharged as clean sewage, and the wastewater is mainly domestic sewage from employees.

(3) Noise: The noise sources generated in the production process of this project are mainly grinders, sieving machines, granulators, extruders, air compressors, mixers, balers, palletizers, forklifts, fans, boilers, etc. Operation noise of equipment such as soft water preparation system.

(4) Solid waste: The solid waste generated during the production process of this project mainly includes dust collected by the dust collector, raw material sieve residues, raw material waste packaging, unqualified products, waste reverse osmosis membranes generated by the replacement of soft water treatment equipment, and employee household garbage .

10. The rationality of site selection

The 2t/h expanded corn processing and 18t/h poultry feed mill plant project site is located 410 meters southwest of Xibuyin Village, Baotai Town, Pingyi County, Linyi City. There is no bad geology in the area and it is suitable for plant construction. After effective pollution prevention and control measures are taken during the production and operation of the project, the pollutants are discharged to the surrounding area. The environmental impact is small; the environmental protection distance requirements are met; the environmental management requirements are met, and the water, electricity, and gas supply around the project are guaranteed, and the transportation is convenient. There are no scenic spots, ecological fragile zones, etc., and according to Pingyi County Baotai A certificate issued by the Town, Village and Town Construction Service Center shows that the construction of this project meets the requirements of the overall planning of Baotai Town, Pingyi County, so the site selection of this project is reasonable.

Richi Machinery——A professional poultry feed mill manufacturer in china. If you want to make a poultry feed mill business plan, plaese feel free to contact us. Want to know more poultry feed mill projects from Richi Machinery? Click here:https://www.cn-pellet.com/case/animal-feed-plant

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy