- SUCCESS STORIES

- Home → Success Stories

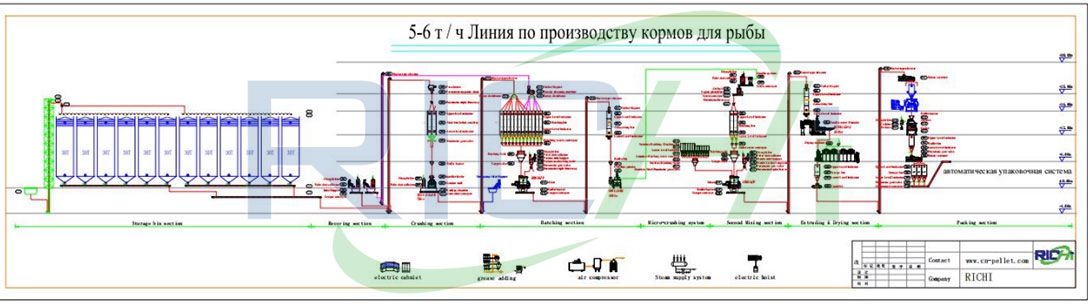

This feed production line is mainly used to produce fish feed pellets such as sturgeon, trout, etc. The customer is from Russia, the capacity of this fish feed production line is 5 tons per hour. It is a fully automatic fish feed production line.

Relying on this fish feed production line, customers can use different raw materials such as soybean meal, bran, fish meal, etc. to produce fish feed, and the pellet size can be adjusted according to specific needs. This fish feed production line is fully installed and the customer has started its start-up.

After the idea of "building a complete fish feed production line" was confirmed, he started to search for manufacturers who could produce fish feed production lines online. After looking at our website, he thought we were a relatively professional manufacturer, so he started asking us about the details of the device.

It is a relatively big project for the customer, and it is a turnkey project, so the customer was always more careful and had many ideas and needs. We changed the design plan many times according to the customer's needs, and finally reached the customer's goal Satisfied, decided to order our equipment.

This is a fully automatic line for the production of fish feed. The entire production process includes the processing of raw materials up to the packaging of the finished pellets. Particularly in the field of packaging, the customer requires the use of fully automatic packaging equipment. The whole production process can improve the efficiency of fish feed production and save labor.

After the raw material is crushed in the crusher, it not only promotes bloating and pelletizing, but also improves the nutrient utilization rate of the raw material.

We equipped this fish feed production line with a shredding system and, at the same time, according to customers' needs, also equipped it with an ultra-fine shredder.

According to the feed formulation requirements, the chopped materials and various additives, oil and water can be evenly mixed in the mixer.

The main equipment used in this section is a fish feed extruder. The mixed material is fed to the conditioner through a frequency conversion screw feeder and water and steam are added to mature the material.

After extrusion, wet and soft pellets are formed (25% to 30% moisture content). To reduce particle breakage, it is recommended to use pneumatic transport to send the material from the extruder through the feed pipe to the dryer for drying, so that the moisture content of the material is reduced to about 13%.

After the foamed pellets are dried, oil, vitamins, flavorings, etc. are sprayed on the surface to promote oil absorption and meet the energy needs of fish. And it can improve the flavor of feed and reduce the content of powder.

According to the degree of automation of weighing and filling and packing in packing operations, it can be divided into three types: manual packing, semi-automatic packing and fully automatic packing. For this fish feed production line, the customer requires a fully automatic packaging system.

After our project plan is confirmed by the customer, we will proceed to manufacture the equipment. All the equipment required for this fish feed production line is manufactured in our own factory.

The basic equipment needed for fish feed production line such as fish feed extruder, grinder, mixer, etc., a certain cycle is required to produce this equipment.

Therefore, from time to time we send the customer pictures, videos or production process of the manufactured equipment or semi-finished product so that they can see the whole production process of the equipment they have purchased.

All equipment is manufactured and shipped to the customer within the agreed time frame. We have a complete delivery process, so no matter where the customer's project is being built, we can guarantee that the equipment will be shipped to the customer's project site.

After receiving the equipment, the customer must install and debug the equipment. There are generally two installation methods. One is that we send our engineers to the customer's project site to help the customer install it. The other is that we provide all the drawings and the customer installs it by himself., we can give the manual online.

This customer chooses the second method of installation. Therefore, we provide customers with all the drawings required for installation, including installation drawings, steel structure technology, etc., as well as detailed installation instructions and instructions for use.

The warranty period of this fish feed production line is one year. After the customer's installation is completed, our after-sales service team will immediately contact the customer to discuss the commissioning and operation of the production line.

Our after-sales staff will explain and solve any problems customers encounter during the production process.

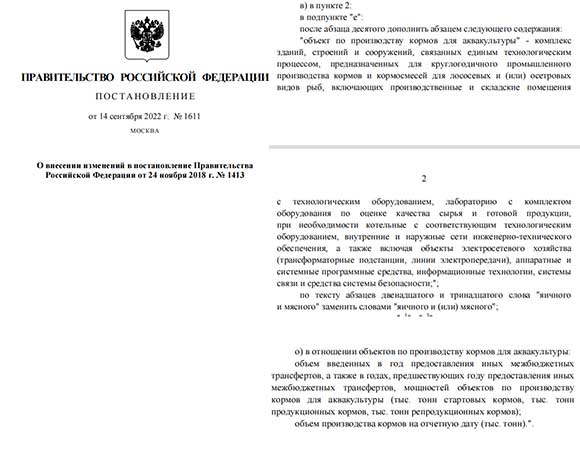

From 2023, 20% of costs for the construction or modernization of workshops for the production of feed for salmon and sturgeon are to be compensated The Government is expanding the range of measures to support producers of feed for the farming of salmon and sturgeon. The corresponding Decree (dated September 14, 2022, No. 1611) was signed by Prime Minister Mikhail Mishustin.

According to the document, from 2023, the Government will compensate 20% of the costs of construction or modernization of feed production facilities for valuable species of salmon and sturgeon.

The signed document amends Government Resolution No. 1413 of November 24, 2018.

The support measure will help reduce dependence on imported feed and promote further development of salmon and sturgeon farming in Russia to supply the domestic market with fish products.

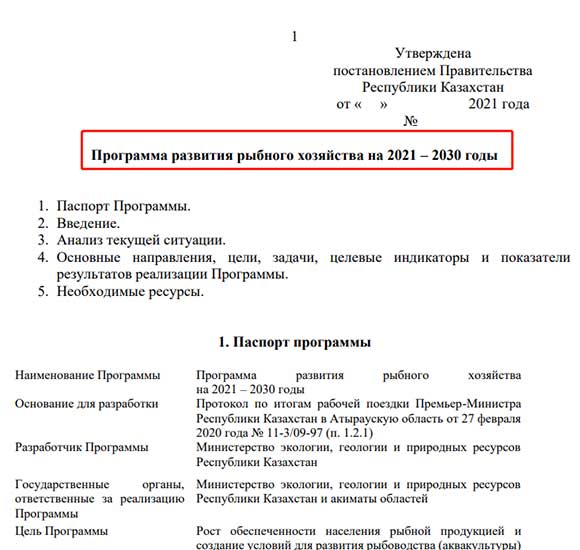

Program Goal: Increase of fish products availability and creation of conditions for fish farming (aquaculture) development

Our fish feed production line is exported to Russia, Kazakhstan, Uzbekistan, etc. Most of the projects are turnkey projects, i.e. complete fish feed production line. Of course, some customers only purchase separate equipment for fish feed production. So now we have mature experience in manufacturing fish production equipment. And our process is relatively complete, from design, production, delivery, installation to after-sales service, there are professional staff to contact customers at any stage. Whether you want to buy complete fish feed production line or separate fish feed production equipment, we can meet your needs.

Get QuoteIf you have any questions, please contact our Executive Manager and we will get back to you as soon as possible

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible.