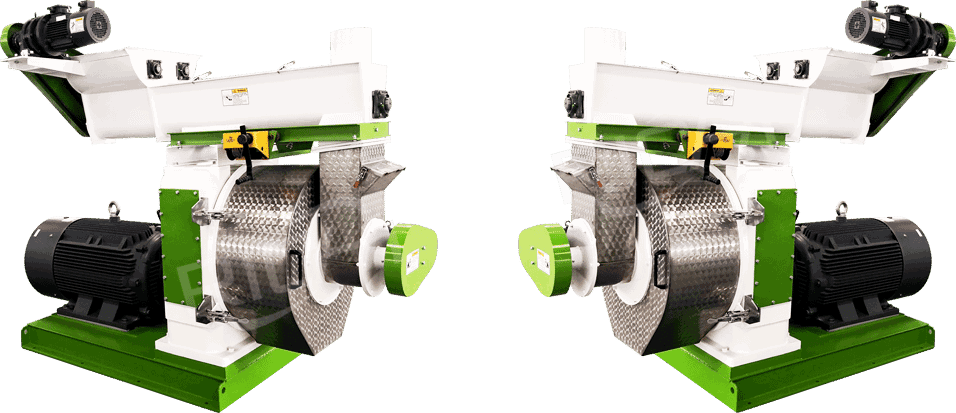

- Brand : RICHI

- Capacity : 2.5-4T/H

- Model : MZLH768

- Main Power : 250KW

-

Guiding Price :

FOB 60000-100000 USD

Brief Introduction

A large amount of crushed raw material enters the pellet mill and filled between the press roller and the ring die, continuously compress the material at a high speed, finally extrude the finished particles.

Get QuoteWood sawdust pellet mill at an effective solution to several problems: Biological crude fiber, deformed granules, poor granulation. The main drive adopts high-efficiency gear transmission, which is more than 20% more efficient than the traditional belt drive. In addition, the ring die adopts the quick release type hoop type, the feeding adopts the frequency conversion speed feeding to ensure the uniform feeding, the door cover is equipped with the forced feeder, and is manufactured by international advanced manufacturing technology, and we can provide all kinds of pellet machines for you. Tailor-made high-quality molds for various raw materials, so that your equipment life is extended, product quality is improved, and tons of consumption costs are reduced.

| Model | Anti-caking Feeder Power | Forced Feeder Power | Pellet Machine Power | Capacity (wood sawdust) | Capacity (grass,straw) | Capacity (organic fertilizer) | Final Pellet |

| MZLH768 | 3KW | 1KW | 250KW | 2.5-4 T/H | 5-7 T/H | 9-10 T/H | 6-12mm |

Sawdust Pellet Mill

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Capacity | 300-400kg/h | 500-700kg/h | 1.0-1.2 t/h | 2.0-2.5 t/h | 2.5-4 t/h | 3-4.5 t/h |

| Power | 37kw | 55kw | 90kw | 110/132kw | 250/280kw | 280kw |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

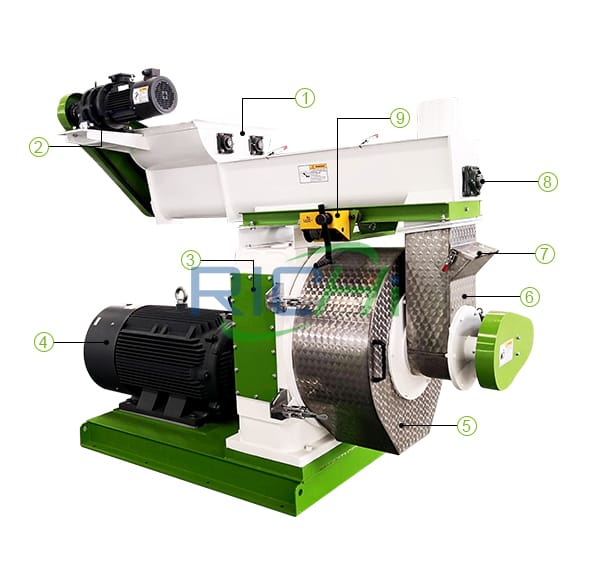

What Are The Parts of Sawdust Pellet Mill?

Sawdust Pellet Mill is a key equipment for the production of pellets, which composed of multiple components. It is mainly composed of drive system, feeding system, pelletizing system, etc. The following figure is for reference. It can be seen that in order to adapt to the particularity of the raw materials, we have increased the size of the feeding port and added a forced feeder, which not only solves the problem of low production efficiency of biomass particles, but also effectively reduces waste of raw materials.

Contact Us-

-

1. Feeder

2. Feeder Motor

3. Gearbox

4. SIEMENS Motor

5. Pelleting Chamber

6. Forced Feeder

8. SKF Bearing

9. Lifting device

Detailed Instructions of Sawdust Pellet Mill

RICHI always believes that good products are one of the important indicators of corporate survival. We use high-standard materials in the production process and cooperate with internationally renowned brands to ensure that we can bring high-quality equipment to customers. The following is a detailed display of RICHI Sawdust Pellet Mill.

Contact Us-

Connected to the air duct, there is a mesh in the box to prevent the finished pellets from overflowing

-

This small lifting device can help user to replace the very heavy ring die and roller assembly

-

Frequency Control Feeder with Anti-caking device

-

Protect machine(Producting main shaft, rotor and ring die)

-

Siemens Motors

-

304 stainless steel ring die, corrosion resistance, Full automatic CNC ring die drilling machine and vacuum heat treatment technology

-

Press Roller Section - Made of 40CrMnTi, the structure of the eccentric shaft can better adjust the distance between the ring die and press roller

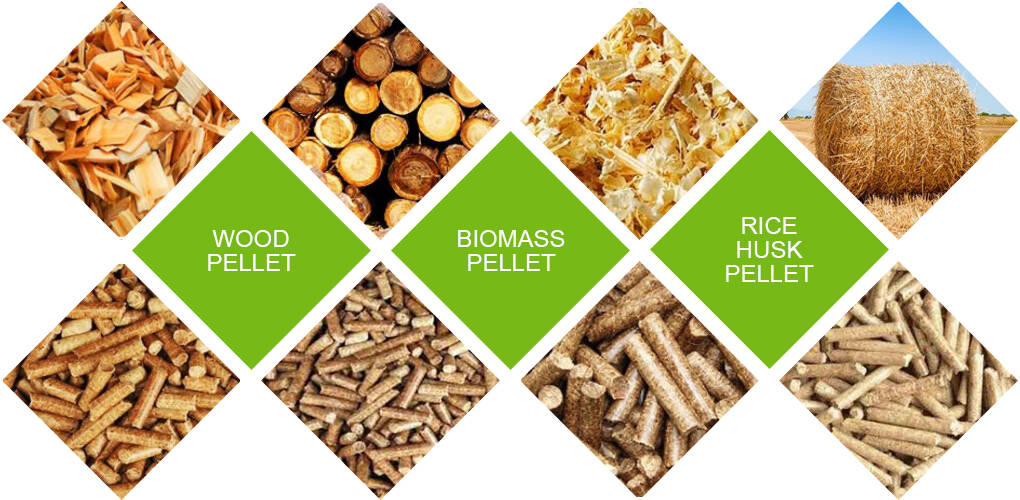

Application of Wood Sawdust Pellet Mill

The wood sawdust pellet mill uses logs, wood chips, sawdust, straw and bamboo chips as raw materials. Wood sawdust pellets can be used as fuel pellets, or horse bedding.

Contact Us

Equipment In RICHI Workshop

- Wood Pellet Mill

- Sawdust Pellet Mill

- Wood Sawdust Pellet Machine

- Sawdust Pellet Plant

Related Pellet Production Line

Our products are usually used in conjunction with other equipment in the pellet production line and have a wide range of applications. The following are common pellet production lines for reference only. If you have different raw materials or different requirements, please contact us for customization.

Contact UsCases

-

Low Cost Small Capacity 400KG/H Wood Pellet Production Plant For Wood Mushroom-Stick Crop Waste

Country : Guizhou Province, China

Capacity: 400KG/H

-

Turn-key China Professional 10TPH Biofuel Pellet Plant Project For Wood And Straw Waste

Country : China

Capacity: 10T/H

-

Professional Design Low Consumption 8T/H Wood Peanut Shell Straw Pellet Manufacturing Plant Project In China

Country : China

Capacity: 8T/H

-

Large 20 tons per hour biomass agricultural and forestry waste wood fuel pellet production plant project in China

Country : Hainan Province, China

Capacity: 20T/H

-

High return 4tph orange peel forestry wood waste pellet manufacturing plant project in China

Country : Hunan Province, China

Capacity: 4T/H