Chicken Feed Pellet Making Machine - The Guide To Buying And Using

What are chicken pellets made of?

Different types of chickens have different feed formulas, and chickens at different growth stages have different feed formulas. For example, the feed formula for brooding chickens is: corn 44%, bean cake 15%, stone powder 1.5%, calcium hydrogen phosphate 1.1%, methionine 0.05%, lysine 0.05%, premix 0.50%, fish meal 1.5%, sorghum 10%, low-quality flour 10%, peanut cake 8%, wheat bran 8%. After all these raw materials are mixed, they are made into pellets by a chicken feed pellet making machine.

How to make chicken feed pellets of your own?

RICHI recommendation steps to make chicken feed pellets

- Step 1. Prepare raw materials.

Different types have different formulas, and different growth cycles also have different formulas. Generally speaking, the raw materials are corn, bean cake, stone powder, peanut cake, wheat bran, and other nutrients. - Step 2. Raw material processing

Most raw materials need to be crushed. RICHI recommends using a professional feed crusher. - Step 3. Raw material mixing

According to different formula requirements, all raw materials must be fully mixed in a certain proportion. We recommend that you use a professional feed mixer. - Step 4. Press the mixed raw materials into pellets by chicken feed pellet

making machine

- The mixed material is then fed into a chicken feed pellet machine and pressed into pellets. For long-term use, you must store the finished chicken feed pellets in a dry and ventilated place to avoid mold and deterioration

With the above information, you can make high-quality pellet feed for chicken. Homemade chicken balls are cost-effective, maintain the nutritional balance of the chicken, and ensure the health of the chicken. The chicken feed pellet machine not only allows you to be self-sufficient but can even trade feed pellets, which is a high return investment.

Learn more: How to build your animal feed mill plant?What is a chicken feed pellet making machine?

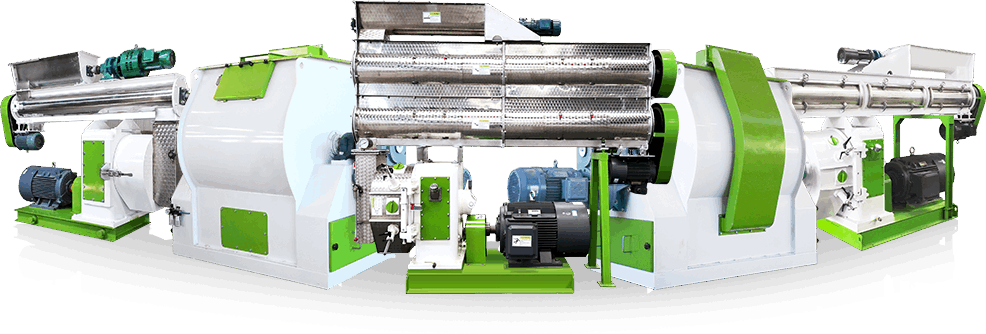

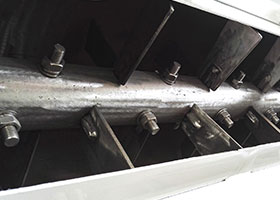

The chicken feed pellet machine is chicken feed pelletizing equipment. It is a chicken feed

making machine that directly compresses the pellets of crushed corn, soybean meal, etc.

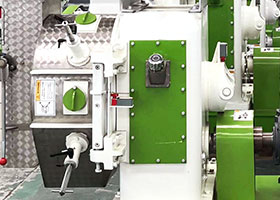

The chicken feed making machine is widely used in large, medium, and small livestock farms,

poultry farms, individual farmers, and small and medium farms, farmers, or large, medium and

small chicken feed mill plants.

The chicken feed pellet machine has the following advantages:

- Wide adaptability to raw materials.

- Powdery feed and grass meal can be pelletized without or with a little liquid addition, so the moisture content of pellet feed is basically the moisture content of the material before pelleting, which is more conducive to storage.

- Making pellet feed can obtain higher economic benefits than mixing powder feed.

- Dry feed processing, the produced feed pellets have high hardness, smooth surface, and internal maturation, which can improve the digestion and absorption of nutrients.

- The granule formation process can denature the pancreatic enzyme resistance factor in grains and beans, reduce the adverse effects on digestion, kill all kinds of parasite eggs and other pathogenic microorganisms, and reduce all kinds of worms and digestive system diseases.

How does a feed pellet machine work?

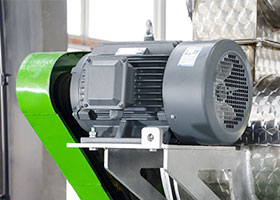

How does a chicken feed pellet making machine work? When you feed raw materials into the chicken feed pellet machine through the hopper, they fall on the ring die and spread over it under the function of roller. When you start the chicken feed pellet machine, the electric motor runs and brings along the main shaft through the gearbox.

How to start a chicken feed mill plant?

Carry out market research on chicken feed plant

- Local market environment.

- Development and scale of aquaculture industry.

- Number and scale of chicken feed manufacturers, and chicken feed pellet making machine.

Receive training and technology for chicken feed pellet formulation

- Understand chicken feed pellet formula.

- Understand raw materials and how to buy raw materials.

- Understanding the different growth cycles of chickens requires changing different formulas.

Develop business plan for chicken feed pellet plant

- Determine the type of feed that needs to be produced.

- Determine the production scale, such as: one ton per hour, ten tons per hour, etc.

Find a good location for your chicken feed pellet making machine

- Find a suitable land to build a chicken feed mill plant with sufficient electricity and water..

Purchase equipment and machinery of a chicken feed mill plant

- Contact a professional chicken feed pellet making machine manufacturer to consult in detail and determine the process plan and all equipment list of the chicken feed pellet production line. Here RICHI suggests that you must find a professional chicken feed pellet machine manufacturer, preferably a qualified chicken feed pellet making machine manufacturer and exporter.

Purchase raw materials and start pelletizing

- After the chicken feed pellet production line is built, the raw materials can be purchased according to the established formula, and then the chicken feed pellet can be produced.

Brand and market your poultry feed plant

How to buy chicken feed pellet making machine from China?

Buying a chicken feed pellet machine from China is easy now. However, you should research before settling for a chicken feed making machine supplier.

Decide on production capacity

First, you must decide on production capacity. Do you want 1t/h chicken feed pellet machine、5t/h chicken feed pellet machine、10t/h chicken feed pellet machine、more or less? Answering this question will help you make the right investment option.

Model of production

Once you decide on how the capacity you’ll make, the next step is to decide on the production model. That is, manual or automatic. As you know, manual production is labor-intensive but cheap to maintain. On the other hand, the cost of automatic production is very high, but its output and efficiency cannot be matched manually.

Raw materials

In fact, it is necessary to understand the formula. If you buy our chicken feed pellet making machine here, we can recommend a general chicken feed pellet formula for you.

Brand

This is the most crucial step since buying from a chicken feed pellet making machine manufacturers. Fortunately, RICHI provides you high-quality chicken feed pellet making machine that feature modern technology, sturdy frame.

Shipping cost

Depending on your country or location, you might incur high shipping fees. So, ask the pellet making machine supplier or manufacturer how much it will cost you before making the purchase of chicken feed pellet making machine. (RICHI reminds you: Due to the different shipping companies and the complicated external environment, the daily ocean freight may not be the same. So when you consult us about ocean freight, please be patient, because we also need the shipping company to give us Quote for the day.)

How to get chicken feed making machine price?

As a reliable and experienced manufacturer and supplier of poultry feed making machine, we can not only provide a single poultry feed making machine price but also customize a complete poultry feed production line. If you want to build your own poultry feed pellet production line to produce poultry feed pellets, then you need to prepare at least ten thousand dollars. So we suggest you leave your requirements in the form below:

- What pellet feed do you want to produce, big/medium/small chickens; broilers; laying hens?

- How much capacity do you expect? (We can customize 1-100 tons per hour chicken feed production line)

- Do you have your own poultry farm and how many chickens do you have?

- Is this a commercial project whose purpose is to sell chicken feed?

- Are resources such as land and electricity ready?

- If you just want to invest in this industry, then you can tell us your budget and needs, and we will redesign the plan and customize a feed production line to meet your requirements.