- Brand : RICHI

- Capacity : 300-400KG/H

- Model : MZLH320

- Main Power : 22KW

-

Guiding Price :

FOB 10000-20000 USD

Brief Introduction

The material passing through the conditioner enters the pelleting chamber, pass through the ring die and pressure roller, and forms cylindrical pellets under the action of high speed and pressure. The length can be controlled by the cutter. Therefore, the pelletizer is the core equipment in pellet production. RICHI MZLH model biomass pellet machine can adapt to the production of a variety of raw materials (wood log, sawdust, agricultural and forestry waste, husk, fiber, etc). Large output and high efficiency. Contact us for more guidance on the biomass pellets production and a quotation for our equipment and solution.

Get QuoteRICHI biomass pellet mill, the support bar and main shaft are forged together, keep uniform gap between roller and ring die, ensure high efficiency. Output increases 10-12%, reduce maintenance rate. Add oil when starting up, user can set the adding oil volume and period according to the case, avoid wrong operation hurting the machine. Stainless steel gate, long durability. Pneumatic fast discharging gate, avoid burning the motor or damage the equipment. Forged bearing, long durability.

| Model | Anti-caking Feeder Power | Forced Feeder Power | Pellet Machine Power | Capacity (wood sawdust) | Capacity (grass,straw) | Capacity (organic fertilizer) | Final Pellet |

| MZLH320 | 1.5KW | 0.55KW | 37KW | 300-400KG/H | 600-800KG/H | 1-2 T/H | 6-12mm |

Biomass Pellet Mill

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Capacity | 300-400kg/h | 500-700kg/h | 1.0-1.2 t/h | 2.0-2.5 t/h | 2.5-4 t/h | 3-4.5 t/h |

| Power | 37kw | 55kw | 90kw | 110/132kw | 250/280kw | 280kw |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

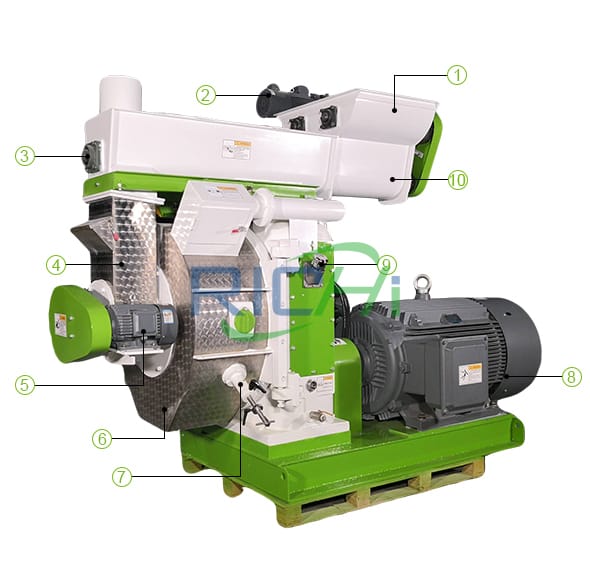

What Are The Parts of Biomass Pellet Mill?

Biomass Pellet Mill is a key equipment for the production of pellets, which composed of multiple components. It is mainly composed of drive system, feeding system, pelletizing system, etc. The following figure is for reference. It can be seen that in order to adapt to the particularity of the raw materials, we have increased the size of the feeding port and added a forced feeder, which not only solves the problem of low production efficiency of biomass particles, but also effectively reduces waste of raw materials.

Contact Us-

-

1. Feeder

2. Feeder Motor

3. SKF Bearing

4. Forced Feeder

5. Forced Feeder Motor

6. Pelleting Chamber

7. Cutter Assembly

8. SIEMENS Motor

9. Gearbox

10. Conditioner

Detailed Instructions of Biomass Pellet Mill

RICHI always believes that good products are one of the important indicators of corporate survival. We use high-standard materials in the production process and cooperate with internationally renowned brands to ensure that we can bring high-quality equipment to customers. The following is a detailed display of RICHI Biomass Pellet Mill.

Contact Us-

Connected to the air duct, there is a mesh in the box to prevent the finished pellets from overflowing

-

This small lifting device can help user to replace the very heavy ring die and roller assembly

-

Frequency Control Feeder with Anti-caking device

-

Protect machine(Producting main shaft, rotor and ring die)

-

Siemens Motors

-

304 stainless steel ring die, corrosion resistance, Full automatic CNC ring die drilling machine and vacuum heat treatment technology

-

Press Roller Section - Made of 40CrMnTi, the structure of the eccentric shaft can better adjust the distance between the ring die and press roller

Application of Biomass Pellet Mill

This series of biomass pellet machine, not only capable of handling a variety of agricultural and forestry waste (wood log, sawdust, straw), husk, fiber, etc., can also handle animal manure. It can be said that as long as it is organic, it can be used as raw material to produce pellets.

Contact Us

Equipment In RICHI Workshop

- Biomass Pellet Mill

- SKF Bearing

- Siemens Motor

- Biomass Pellet Machine

Related Pellet Production Line

Our products are usually used in conjunction with other equipment in the pellet production line and have a wide range of applications. The following are common pellet production lines for reference only. If you have different raw materials or different requirements, please contact us for customization.

Contact UsCases

-

Low Cost Small Capacity 400KG/H Wood Pellet Production Plant For Wood Mushroom-Stick Crop Waste

Country : Guizhou Province, China

Capacity: 400KG/H

-

Turn-key China Professional 10TPH Biofuel Pellet Plant Project For Wood And Straw Waste

Country : China

Capacity: 10T/H

-

Professional Design Low Consumption 8T/H Wood Peanut Shell Straw Pellet Manufacturing Plant Project In China

Country : China

Capacity: 8T/H

-

Large 20 tons per hour biomass agricultural and forestry waste wood fuel pellet production plant project in China

Country : Hainan Province, China

Capacity: 20T/H

-

High return 4tph orange peel forestry wood waste pellet manufacturing plant project in China

Country : Hunan Province, China

Capacity: 4T/H