- Brand : RICHI

- Capacity : 3-5T/H

- Model : SKLN14*14

- Main Power : 0.75KW

-

Guiding Price :

FOB 4000-20000 USD

Brief Introduction

New feeder to ensure that the spread of material sufficiently homogeneous, thorough cooling and significantly reduced breakage rate, adjustable range of fabrics, a small power consumption.

Get QuoteRICHI Counter-Flow FeedPellet Cooler adopts the principle of counterflow cooling, the pellets are cooled and evenly distributed; the unique sliding valve type discharging mechanism is used for discharging; the sliding valve type discharging mechanism is stable and reliable, and the discharging is smooth; the temperature of the pellet after cooling is not higher than room temperature. +3-5 degrees. An access door is provided on the front of the unit for convenient daily maintenance and overhaul. An observation window is provided on the side for easy observation of the thickness of the material layer in the chamber.

| Model | Capacity(t/h) | Power(kw) |

| SKLN14*14 | 3-5 | 0.75 |

Stainless Steel Pellet Cooling Machine

| Model | SKLN11*11 | SKLN14*14 | SKLN17*17 | SKLN20*20 | SKLN24*24 |

| Capacity(t/h) | 1.5-2 | 3-5 | 5-8 | 9-12 | 13-18 |

| Power(kw) | 0.75 | 0.75 | 1.1 | 2.05 | 2.05 |

Application of Stainless Steel Pellet Cooling Machine

The counter-flow cooler is mainly used in the feed pellet production line. Since the temperature of the pellet just extruded is high, a cooler is required to lower it to room temperature for subsequent screening.

Get QuoteAccessories

RICHI manufactures high-spec accessories using high-quality steel to improve equipment quality and reduce customer maintenance costs.

Get Quote

-

SIEMENS

Motor

-

SKF

Bearing

-

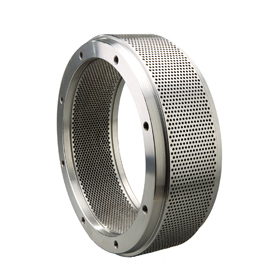

Pellet Machine

Ring Die

-

Pellet Machine

Ring Die

Equipment In RICHI Workshop

- Counter-Flow Cooler

- Feed Pellet Cooler

- Spreading Device

- Discharging Device

Cases

-

Low Cost Small Capacity 400KG/H Wood Pellet Production Plant For Wood Mushroom-Stick Crop Waste

Country : Guizhou Province, China

Capacity: 400KG/H

-

Turn-key China Professional 10TPH Biofuel Pellet Plant Project For Wood And Straw Waste

Country : China

Capacity: 10T/H

-

Professional Design Low Consumption 8T/H Wood Peanut Shell Straw Pellet Manufacturing Plant Project In China

Country : China

Capacity: 8T/H

-

Large 20 tons per hour biomass agricultural and forestry waste wood fuel pellet production plant project in China

Country : Hainan Province, China

Capacity: 20T/H